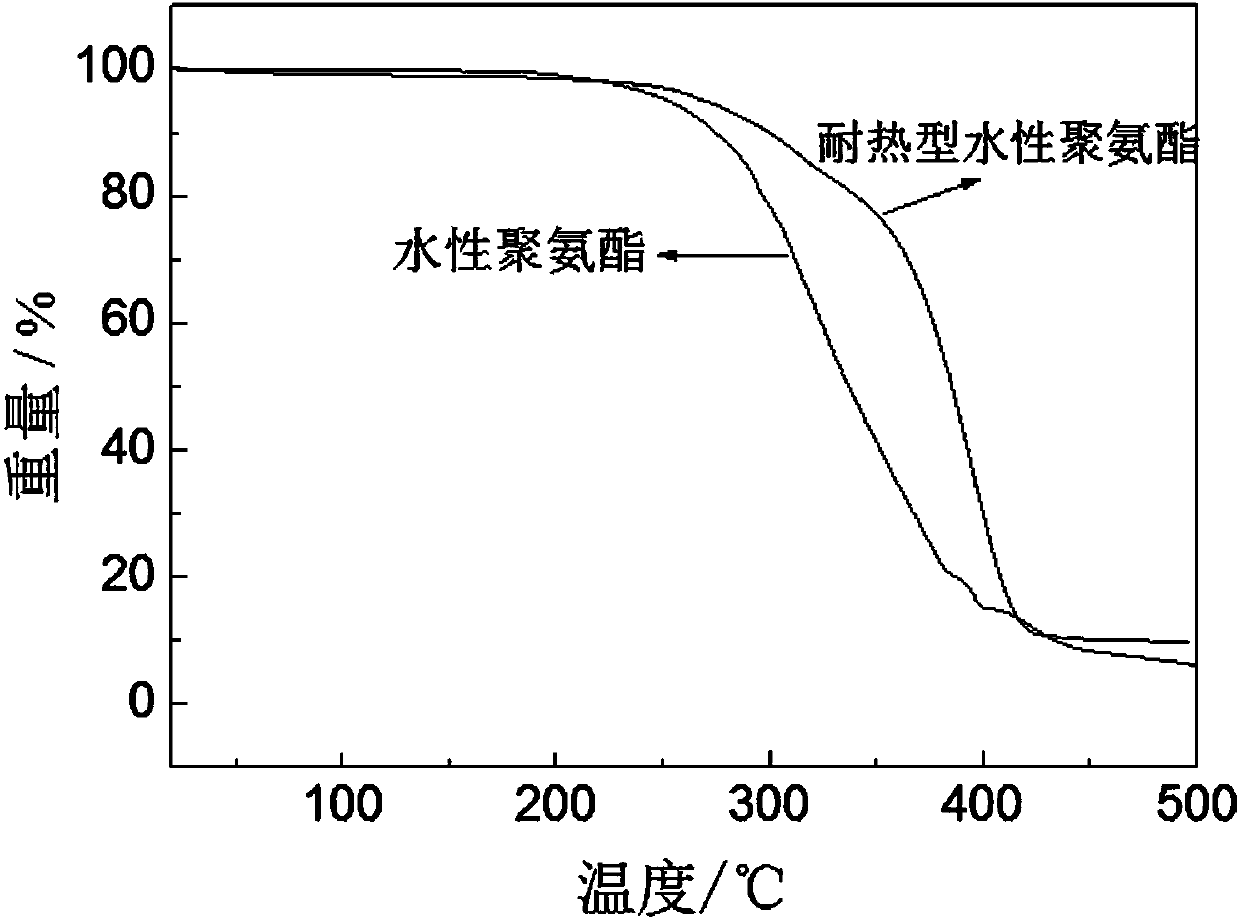

Heat-resistant waterborne polyurethane and preparation method thereof

A water-based polyurethane and heat-resistant technology, which is applied in the field of heat-resistant water-based polyurethane and its preparation, can solve the problems of poor heat resistance and water resistance, improve heat resistance, improve heat resistance and water resistance, and simplify the preparation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Embodiment 1, a kind of heat-resistant waterborne polyurethane of the embodiment of the present invention, is prepared by the following method, and described method comprises the following steps in sequence:

[0040] Step 101, preparing polyurethane prepolymer: mix 46.5% polytetrahydrofuran diol, 15.5% hexamethylene diisocyanate, 33.1% acrylate monomer (20% styrene, 13.1% hexyl acrylate) ) and 0.74% melamine were added to the dry reactor, the reactor was heated to 80°C, stirred evenly, and then the catalyst dibutyltin dilaurate with a mass percentage of 0.1% was polymerized for 2.0 hours to form a polyurethane prepolymer ;

[0041] Step 102, chain extension reaction: the hydrophilic chain extender dimethylol butyric acid with a mass percentage of 1.2%, the reaction temperature is 70°C, and the reaction time is 2.0 hours;

[0042] Step 103, capping reaction: adding 1.6% by mass of hydroxyethyl acrylate into the reactor for capping reaction, the reaction temperature is 8...

Embodiment 2

[0045] Embodiment 2, the embodiment of the present invention provides a heat-resistant water-based polyurethane, which is prepared by the following method, and the method includes the following steps in sequence:

[0046]Step 201, preparing polyurethane prepolymer: mix 40.7% of polyε-caprolactone diol, 18.2% of isophorone diisocyanate, 33.3% of acrylate monomer (wherein methyl methacrylate 22 %, butyl acrylate 11.3%) and 1.3% melamine were added to the dry reactor, the reactor was heated to 80°C, stirred evenly, and then the catalyst dibutyltin dilaurate with a mass percentage of 0.09% was polymerized for 2.0 Hour, form polyurethane prepolymer;

[0047] Step 202, chain extension reaction: the hydrophilic chain extender dimethylol butyric acid with a mass percentage of 2% is used, the reaction temperature is 80°C, and the reaction time is 2.5 hours;

[0048] Step 203, capping reaction: adding hydroxyethyl methacrylate with a mass percentage of 2.8% to the reactor for capping r...

Embodiment 3

[0051] Embodiment 3, the embodiment of the present invention provides a heat-resistant water-based polyurethane, which is prepared by the following method, and the method includes the following steps in sequence:

[0052] Step 301, preparing polyurethane prepolymer: mix 32.8% polytetrahydrofuran diol, 21.8% isophorone diisocyanate, 32.7% acrylate monomer (including 20.5% methyl methacrylate, 20.5% acrylate Octyl ester 12.2%) and 2.1% melamine were added to the dry reactor, the reactor was heated to 80°C, stirred evenly, and then the catalyst dibutyltin dilaurate with a mass percentage of 0.07% was polymerized for 2.5 hours to form Polyurethane prepolymer;

[0053] Step 302, chain extension reaction: dimethylol butyric acid, a hydrophilic chain extender with a mass percentage of 3.2%, is reacted at a temperature of 75° C. and a reaction time of 2.0 hours;

[0054] Step 303, capping reaction: adding 4.5% by mass hydroxypropyl acrylate into the reactor for capping reaction, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com