Imidazole epoxy curing agent micro capsule and preparation method thereof

An epoxy curing agent and imidazole technology, applied in the field of imidazole epoxy curing agent microcapsules and their preparation, can solve the problems affecting the storage period of the curing agent, poor coating effect and thermal stability, etc. , convenient storage and transportation, easy-to-control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Weigh 1g of polysulfone and dissolve it in 30ml of dichloromethane, and add 1g of 1-benzyl-2-methylimidazole to it; (2) Use an ultrasonic oscillator to disperse it evenly and use it as the oil phase; (3) Add the obtained oil phase to 300ml aqueous solution containing 1wt% polyvinyl alcohol at 30°C and 750rpm, and then stir at 35°C for 5 hours to let the dichloromethane volatilize slowly to obtain polysulfone-coated imidazole solidified (4) After sieving, washing with water, suction filtration and drying, a light yellow microcapsule product can be obtained. refer to figure 1 , figure 1 Scanning electron micrographs of the microcapsules prepared for this example. The volume average particle diameter of the prepared microcapsules is analyzed to be about 110 μm, and the capsule core content is 25%.

Embodiment 2

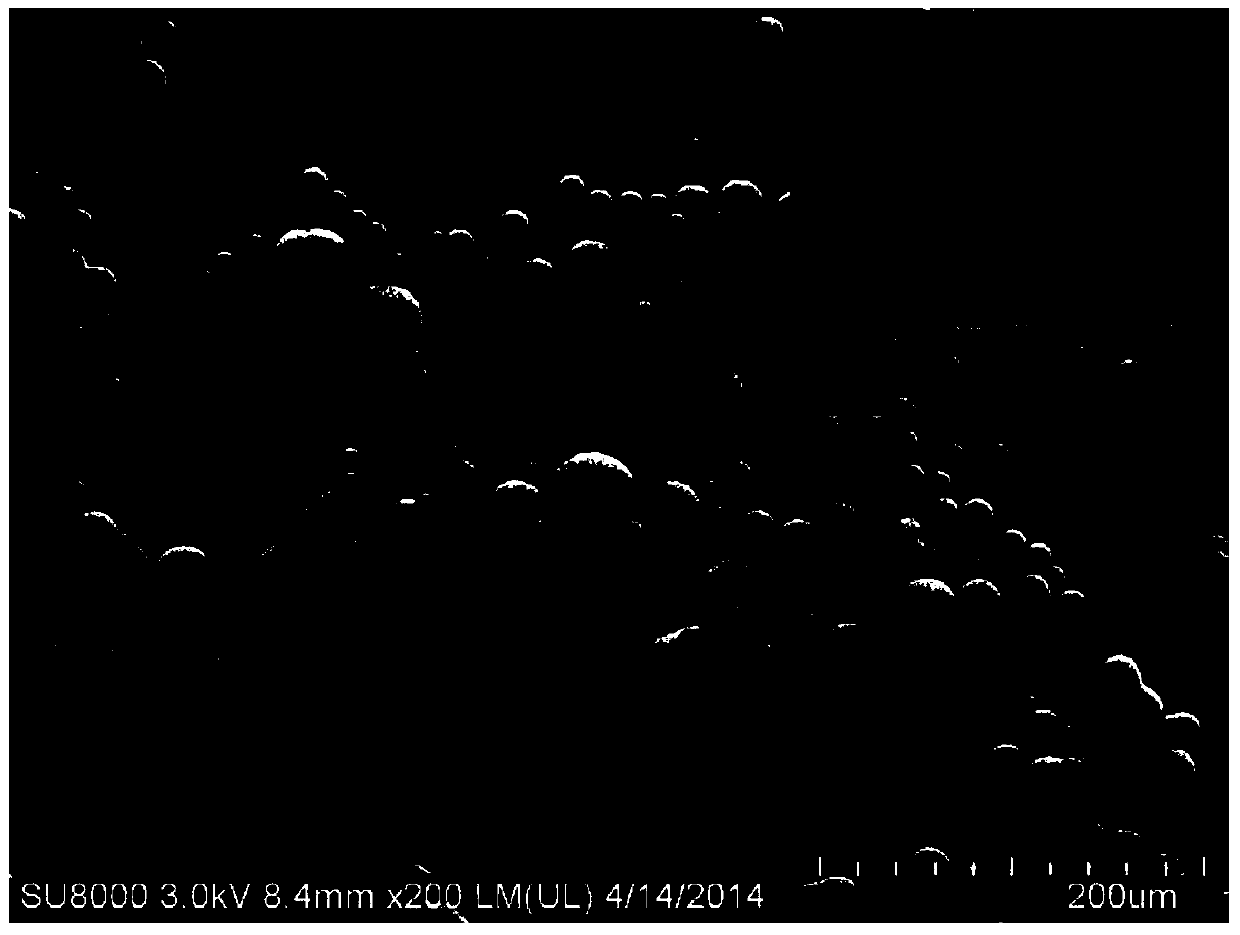

[0028] (1) Weigh 2g of polysulfone and dissolve it in 50ml of dichloromethane, and add 1g of 1-benzyl-2-methylimidazole to it; (2) Use an ultrasonic oscillator to disperse it evenly and use it as the oil phase; (3) Add the obtained oil phase to 500ml aqueous solution containing 1wt% octylphenol polyoxyethylene ether at 30°C and a rotation speed of 1000rpm, then stir at 35°C for 7 hours, let the dichloromethane volatilize slowly, and obtain the polysulfone package Microcapsule suspension covered with imidazole curing agent; (4) light yellow microcapsule product can be obtained after sieving, washing with water, suction filtration and drying. refer to figure 2 , figure 2 Scanning electron micrographs of the microcapsules prepared for this example. The volume average particle diameter of the prepared microcapsules is analyzed to be about 140 μm, and the capsule core content is 23%.

Embodiment 3

[0030] (1) Weigh 1g of polysulfone and dissolve it in 30ml of dichloromethane, and add 2g of 1-benzyl-2-methylimidazole to it; (2) Use an ultrasonic oscillator to disperse it evenly and use it as the oil phase; (3) Add the obtained oil phase to 300ml of aqueous solution containing 1wt% Tween-80 at 30°C and 800rpm, and then stir at 40°C for 7 hours to allow the dichloromethane to volatilize slowly to obtain polysulfone-coated imidazoles Solidifying agent microcapsule suspension; (4) After sieving, washing with water, suction filtration and drying, a light yellow microcapsule product can be obtained. refer to image 3 , image 3 Scanning electron micrographs of the microcapsules prepared for this example. The volume average particle diameter of the prepared microcapsules is analyzed to be about 40 μm, and the capsule core content is 20%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com