EPDM-ENB rubber compound, preparation method and device thereof

A technology of EPDM rubber and compound rubber, which is applied in the field of chemical products and production, can solve the problems of self-adhesion and mutual adhesion, poor wear resistance, air tightness and flame retardancy, and poor flame retardancy and adhesion performance. It can meet the problems of non-polar oil and solvent resistance, and achieve the effect of optimizing production operation, low equipment investment and operating cost, and good flame retardancy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

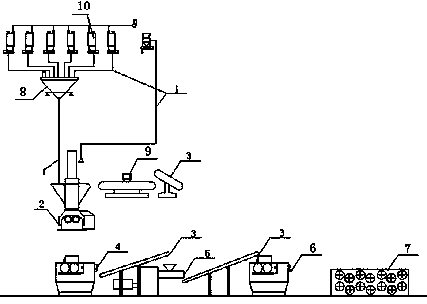

[0025] The preparation method of quaternary ethylene-propylene rubber compound of the present invention, preparation process is as follows:

[0026] ⑴Material preparation process: weigh EPDM rubber, chlorinated polyethylene rubber, softener, reinforcing agent, activator, anti-aging agent, accelerator, lubricant and vulcanizing agent according to the mass ratio;

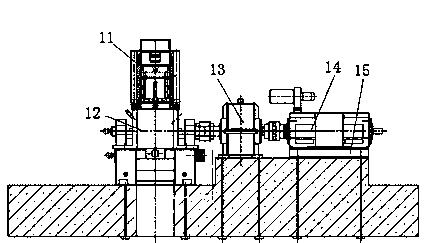

[0027] (2) Mixing process: Preheat the meshing mixer (2) to 100°C to 120°C, add EPDM rubber, reinforcing agent, lubricant, activator, anti-aging agent, softener; add chlorine after 2 minutes of starting Chemicalized polyethylene rubber, control the banburying temperature to 120°C-130°C, and unload after banburying for 2 minutes;

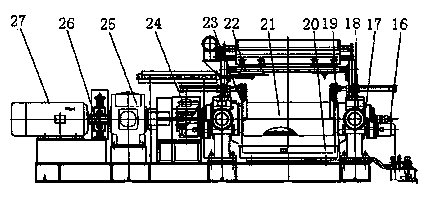

[0028] (3) Tablet pressing process: Preheat the primary mill (4) to 100°C to 120°C, adjust the rotation speed of the primary mill to 50 to 80r / min, and the roller distance to 1mm±0.5mm, add the compound rubber in step (2) Thin pass 3 times in the first-stage open mill to make a mixed film; ...

Embodiment 1

[0033]quaternary ethylene propylene rubber compound, the components are by mass fraction: EPDM rubber 60, chlorinated polyethylene rubber 17, carbon black N330 8, magnesium oxide (Mgo) 5.5, paraffin oil (PO) 5, peroxide Polymerization of dicumyl (DCP) 1N-cyclyl-2-benzothiazole sulfenamide (CZ) 1.6, stearic acid (SA) 0.9 and 2.2.4-trimethyl-1,2-dihydroquinoline Body (RD) 1.0. The preheating temperature of banburying is 105°C, the temperature of banburying is 120°C, the temperature of primary refining is 105°C, and the temperature of secondary refining is 70°C.

Embodiment 2

[0035] EPDM rubber 65, chlorinated polyethylene rubber 15, carbon black N660 8, zinc oxide (zno) 5.5, dioctyl phthalate (DOP) 5, propyl isocyanate (IAIC ) 1, N-cyclyl-2-benzothiazole sulfenamide (CZ) 1.6, stearic acid (SA) 0.9 and MBZ-thiobenzimidazole (MBZ) 1.0. The preheating temperature of banburying is 110°C, the temperature of banburying is 125°C, the temperature of primary refining is 110°C, and the temperature of secondary refining is 75°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com