Complex water-based polymer waterproof coating and manufacturing method thereof

A water-based polymer and waterproof coating technology, applied in the field of waterproof coatings for construction, to achieve the effects of avoiding dust pollution, good integrity, and excellent elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

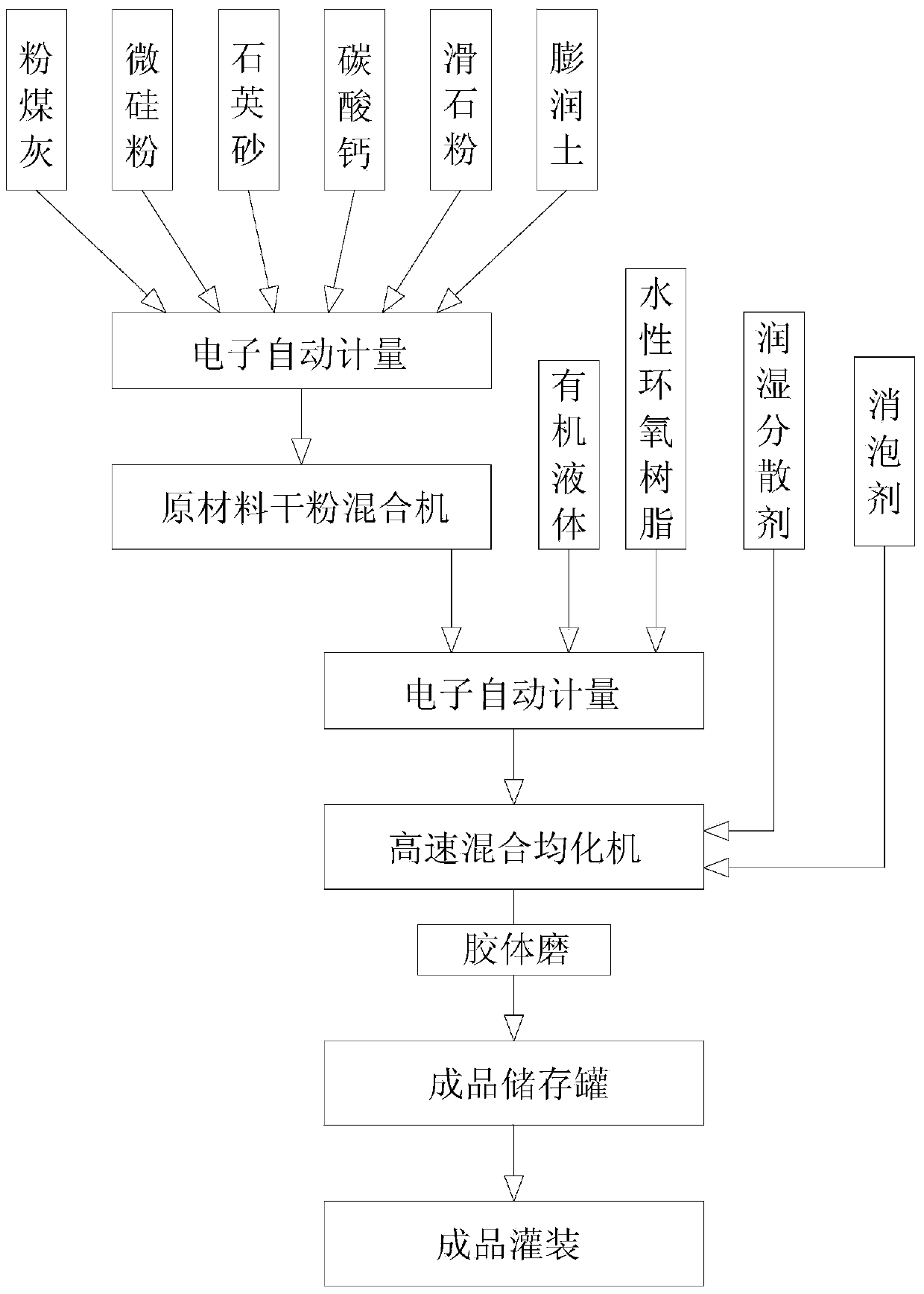

Method used

Image

Examples

Embodiment 1

[0042] The first step raw materials and pre-production preparation:

[0043] 1. Put 500 kg of fly ash, 50 kg of micro silica fume, 300 kg of calcium carbonate, 100 kg of quartz powder, 50 kg of talcum powder, and 50 kg of bentonite. Input the above materials into the raw material weighing hopper according to the weight data, and the raw material screw feeder Automatically metered and transported to the dry powder mixing and stirring equipment, the dry powder was mixed and homogenized for 15 minutes, and the degree of mixing and homogenization reached 99%, and then the finished dry powder after mixing and homogenization was put into the finished product storage bin for use.

[0044] 2. 1000 kg of styrene-butadiene latex and 100 kg of water-based epoxy resin are transported to a high-speed mixing homogenizer for use.

[0045] 3. Weigh 10 kg of wetting and dispersing agent (polyacrylate) for use.

[0046] 4. Weigh 5 kg of defoamer (isopropanol) for use;

[0047] The second step...

Embodiment 2

[0058] The first step raw materials and pre-production preparation:

[0059] 1. Put 250 kg of coal ash, 100 kg of silica fume, 100 kg of calcium carbonate, 250 kg of quartz powder, 100 kg of talcum powder, and 100 kg of bentonite into the solid waste discharged from thermal power plants. Raw material metering hopper and raw material screw feeder are automatically metered and transported to the dry powder mixing and stirring equipment. The dry powder is mixed and homogenized for 10 minutes, and the degree of mixing and homogenization reaches 99%. Then, the finished dry powder after mixing and homogenization is put into the finished product storage bin use.

[0060] 2. 500 kg of vinyl acetate-ethylene copolymer emulsion and 150 kg of water-based epoxy resin are transported to a high-speed mixing homogenizer for use.

[0061] 3. Weigh 5 kg of wetting and dispersing agent (naphthalene sulfonate condensation polymer) for use.

[0062] 4. Weigh 10 kg of defoamer (polypropylene gly...

Embodiment 3

[0074] Its specific content is similar to that of Example 1, except that organic color paste is added to the manufacturing materials of the product according to customer requirements, and iron oxide toner can also be added to prepare different color finishes.

[0075] That is to say, on the basis of maintaining its basic functions, the product complex water-based polymer waterproof coating of the present invention can add some functional materials (such as: toning) according to customer needs.

[0076] As a variation example of the present invention:

[0077] (1) water-based latex among the present invention can select pure acrylate emulsion, vinyl acetate-ethylene copolymer emulsion, styrene-acrylate copolymer emulsion, styrene-butadiene latex for use. These four kinds of emulsions have the advantages of low cost, not limited by regional materials and shortage factors caused by seasons, and sufficient supply.

[0078] (2) The inorganic low-gelling material in the present inv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bond strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com