Preparation method of magnesite powder briquetting binding agent

A magnesite powder and magnesite technology, which is applied in the field of preparation and magnesite agglomeration binder, can solve the problems of poor magnesite agglomeration effect and inconvenient use of the binder, and achieves ideal shape, Simple preparation method and scientific formula effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

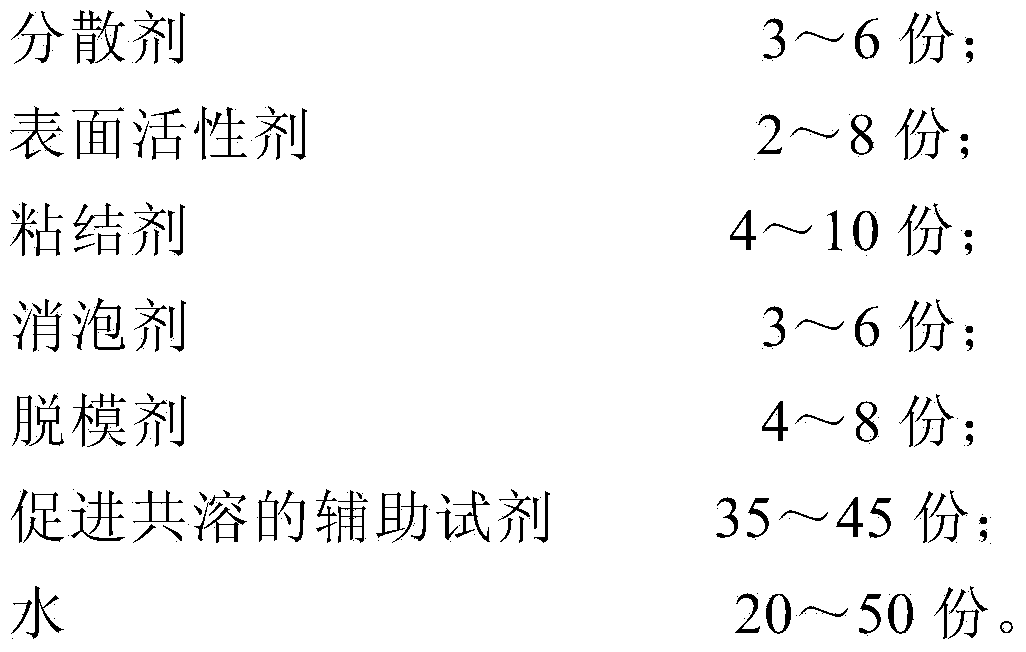

[0026] This embodiment discloses a binder for magnesite agglomeration, which specifically includes the following components by weight:

[0027]

[0028] Wherein, the dispersant is polyvinyl butyral; the surfactant is sodium dodecylbenzene sulfonate; the defoaming agent is glycerin; the binder is sodium methyl cellulose; the release agent is magnesium stearate. The auxiliary reagent used in this embodiment to promote co-dissolution is ethanol.

[0029] The preparation method of the above-mentioned magnesite agglomerate binder includes the following steps: mixing and dissolving the components according to the weight ratio at 90° C. to obtain the magnesite agglomerate binder.

[0030] The use of the magnesite agglomerating binder described in this example in magnesite agglomeration includes mixing and kneading magnesite powder and magnesite agglomerating binder according to a weight ratio of 100:5 , Pressing and molding to obtain magnesite pellets. When magnesite powder is m...

Embodiment 2

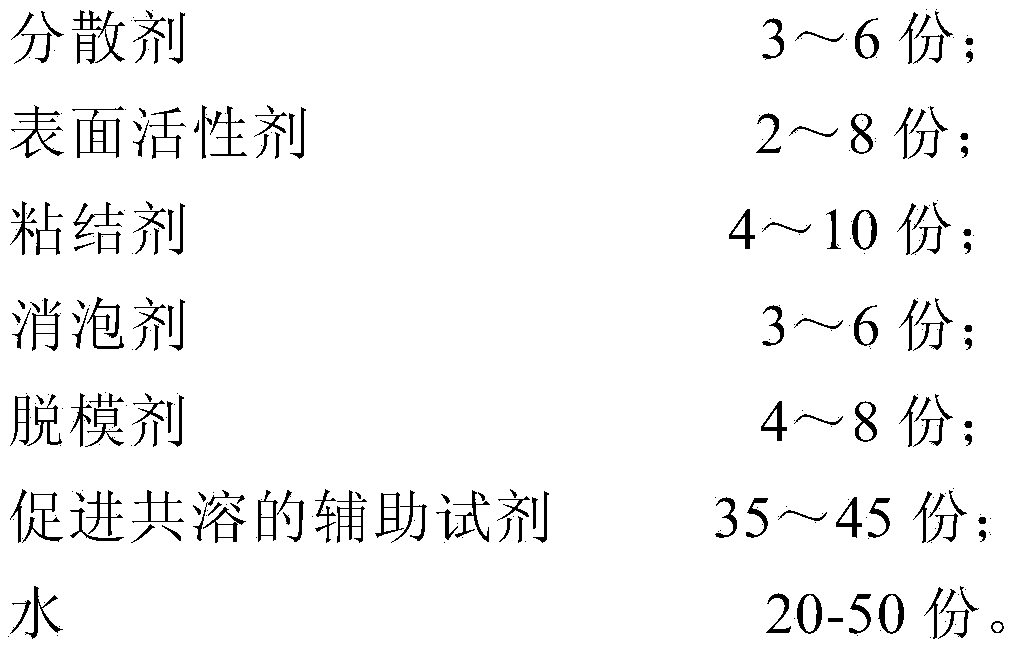

[0032] This embodiment discloses a binder for magnesite agglomeration, which specifically includes the following components by weight:

[0033]

[0034] Among them, the dispersant is polyvinyl butyral; the surfactant is sodium dodecylbenzene sulfonate; the defoamer is octanol; the binder is sodium methylcellulose and polyethylene glycol 1::1 mixture (mass); the release agent is calcium stearate. The auxiliary reagent promoting co-dissolution in this embodiment is ethanol.

[0035] The preparation method of the above magnesite agglomerate binder includes the following steps: mixing and dissolving the components according to the weight ratio at 70° C. to obtain the magnesite agglomerate binder.

[0036] The application of the magnesite agglomerate binder in the magnesite agglomeration process comprises mixing, kneading, and pressing the magnesite powder and the magnesite agglomerate binder according to a weight ratio of 100:10 to obtain Magnesite pellets. When the magnesit...

Embodiment 3

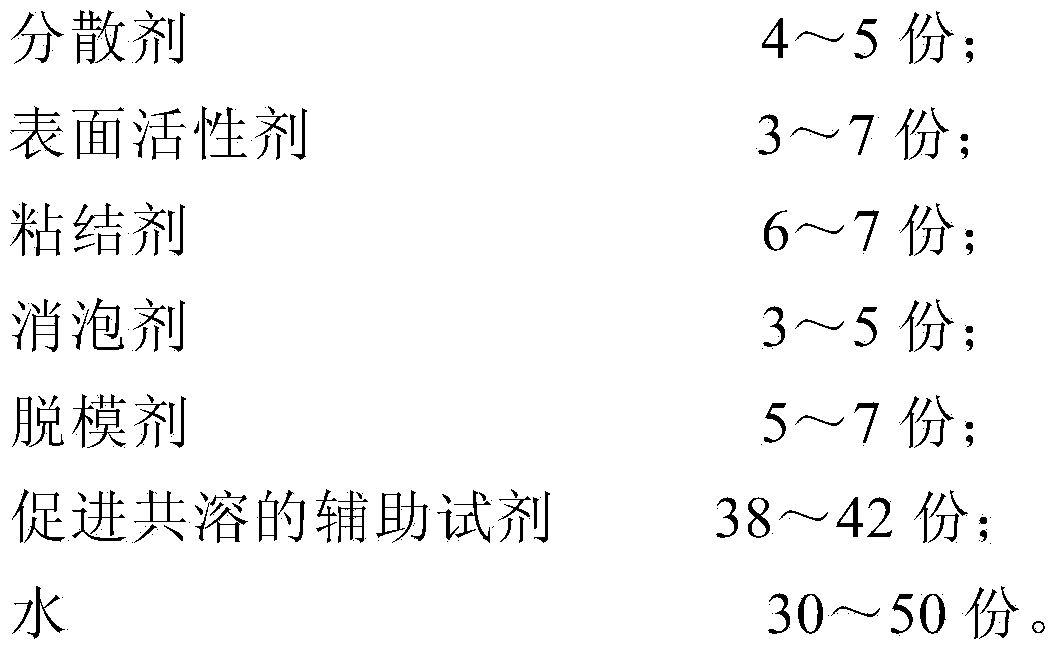

[0038] This embodiment discloses a binder for magnesite agglomeration, which specifically includes the following components by weight:

[0039]

[0040] Among them, the dispersant is polyvinyl butyral; the surfactant is sodium dodecylbenzenesulfonate; the defoamer is glycerin and octanol; the binder is sodium methylcellulose; the release agent is stearin A mixture of magnesium stearate, calcium stearate and sodium stearate. In this embodiment, the auxiliary reagents for promoting co-dissolution are ethanol and methanol, and the mass ratio of ethanol and methanol is 1:1.

[0041] The preparation method of the magnesite agglomeration binder in this embodiment includes the following steps: mixing and dissolving the components according to the weight ratio at 100° C. to obtain the magnesite agglomeration binder.

[0042] The application of the magnesite agglomeration binder in the magnesite agglomeration of this embodiment includes mixing, kneading and pressing magnesite powde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com