Preparation method of lithium-selenium battery positive electrode

A battery positive electrode, lithium-selenium technology, applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of reducing battery energy density, poor electrode cycle performance, peeling of active material particles, etc., to increase energy density and improve cycle performance and rate performance, the effect of reducing contact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

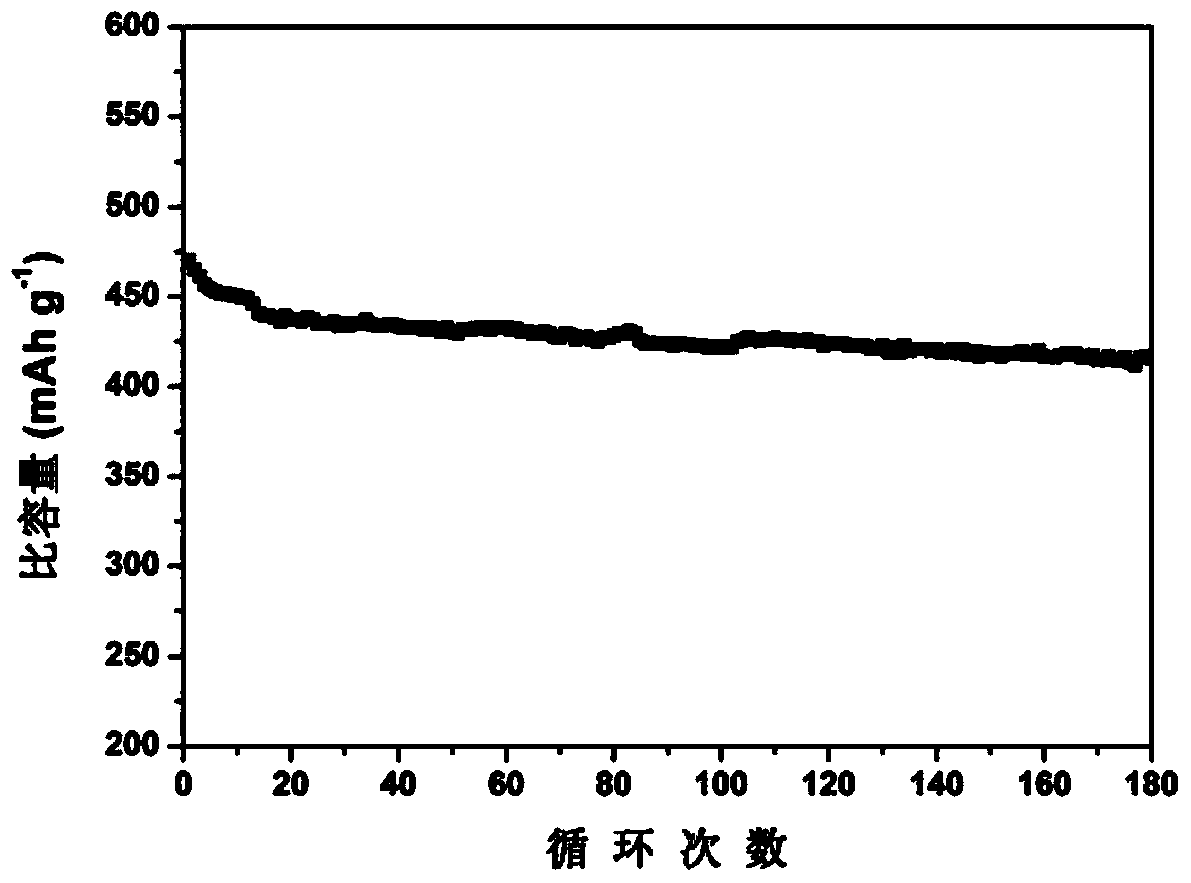

[0035] Deposit or grow 0.05 grams of polyaniline on the surface of filter paper with a thickness of 20 microns and a mass of 0.02 grams, then add 0.2 grams of potassium hydroxide powder to the surface of the filter paper, place it under a nitrogen atmosphere and heat it to 800 ° C for 4 hours to obtain The specific surface area of the current collector with the carbon fiber network structure as the self-supporting body is 850m 2 / g hierarchical porous carbon composite current collector; add 5.0mol / L selenium carbon disulfide solution 1.0mL on the surface of the nitrogen-containing hierarchical porous carbon composite current collector with carbon fiber as a self-supporting body, and dry it in a drying oven at 60°C for 5 hours Remove carbon disulfide, and then place it in a tube furnace under a nitrogen protective atmosphere and heat it up to 260° C. for 10 hours to obtain a lithium-selenium battery electrode with a selenium content of 72%. The lithium-selenium battery electr...

Embodiment 2

[0041] Deposit or grow 0.025 grams of polydopamine on the surface of printing paper with a thickness of 50 microns and a mass of 0.075 grams, and then add 0.075 grams of potassium hydroxide powder to the surface of the filter paper, then place it under a nitrogen atmosphere and heat it to 700 ° C for carbonization for 2 hours , the specific surface area of the current collector with the carbon fiber network structure as the self-supporting body is 550m 2 / g hierarchical porous carbon composite current collector; add 0.5 mol / L selenium carbon disulfide solution 3mL on the surface of the nitrogen-containing hierarchical porous carbon composite current collector with carbon fiber as a self-supporting body, and dry it in a drying oven at 40°C for 2 hours to remove carbon disulfide, and then placed in a tube furnace under a nitrogen protective atmosphere and heated to 600° C. for 10 hours of heat treatment to obtain a lithium-selenium battery electrode with a selenium content of 51...

Embodiment 3

[0043] Deposit or grow 0.05 grams of polypyrrole on the surface of writing paper with a thickness of 10 microns and a mass of 0.01 grams, and then add 0.2 grams of potassium hydroxide to the surface of the filter paper, then place it under a nitrogen atmosphere and heat it to 900°C for carbonization for 5 hours. The specific surface area obtained by using carbon fiber as a self-supporting body is 510m 2 / g hierarchical porous carbon composite current collector; soak the obtained nitrogen-containing hierarchical porous carbon composite current collector with the carbon fiber network structure as a self-supporting body in 3.0mol / L selenium carbon disulfide solution, in a dry box at 50 ° C Dry for 4 hours to remove carbon disulfide, then place in a tube furnace under a nitrogen protective atmosphere and heat up to 300° C. for 15 hours to obtain a lithium-selenium battery electrode with a selenium content of 62%. The lithium-selenium battery electrode prepared in this example is a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com