Attapulgite/polyvinylidene fluoride nano-composite ultra-filtration membrane and preparation method thereof

A technology of polyvinylidene fluoride and polyvinylidene fluoride resin, which is applied in the field of attapulgite/polyvinylidene fluoride nanocomposite ultrafiltration membrane and its preparation, can solve the problems of difficult dispersion, limited scale application, and high preparation cost. To achieve the effect of improving dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The preparation method of the ultrafiltration membrane can be obtained by a common phase inversion method, and after the phase inversion of the cast membrane liquid in the coagulation liquid, an ultrafiltration membrane with a microporous structure can be obtained.

[0039] In the above method, the coagulation liquid is used as a non-solvent, and examples thereof include water; aliphatic hydrocarbons such as hexane, pentane, and trichloroethylene; aromatic hydrocarbons such as benzene and toluene; and mixed solvents thereof. When polyvinylidene fluoride is used as a polymer raw material, water is usually preferably used as the non-solvent of the coagulation bath, but it is not particularly limited as long as it does not dissolve polyvinylidene fluoride. The membrane morphology of the obtained microporous support membrane changes depending on the composition of the polymer solution, and accordingly, the membrane formability of the composite semipermeable membrane also cha...

Embodiment 1

[0048] Add 1 gram of nano-attapulgite to 80 grams of triethyl phosphate, after vigorous mechanical stirring and ultrasonic treatment, add 20 grams of polyvinylidene fluoride powder, stir and dissolve at 80 ° C for 24 hours, and then add 5 grams Polyethylene glycol was stirred for 12 hours to obtain the casting solution, which was left to defoam at 80°C for 24 hours, and the immersion precipitation phase inversion method was adopted. The conditions were: the air dry distance was 0 cm; the flow rate of the casting solution was 2 mL / min; It is deionized water with a flow rate of 2mL / min; the coagulation bath is deionized water with a water temperature of 20-30°C to prepare an attapulgite / polyvinylidene fluoride nanocomposite hollow fiber ultrafiltration membrane with a membrane thickness of about 200 μm. The outer diameter is about 1.0 mm. It has been determined that the pure water flux at 0.1MPa and 20°C is 160 L / (m 2 h) with dextran as the standard substance, its molecular we...

Embodiment 2

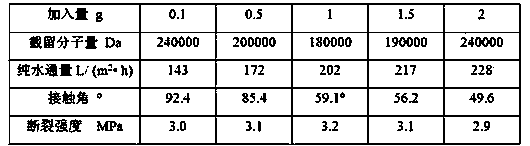

[0054] Add 0.1, 0.5, 1, 1.5, 2 grams of nano-attapulgite to 85 grams of triethyl phosphate, after vigorous mechanical stirring and ultrasonic treatment, add 15 grams of polyvinylidene fluoride powder and stir at 80 ° C Dissolved for 24 hours, then added 5 grams of polyethylene glycol and stirred for 12 hours to obtain a casting solution, left to defoam at 80°C for 24 hours, and adopted the immersion precipitation phase inversion method, the conditions were: the air dry distance was 0 cm; the casting solution The flow rate is 2mL / min; the core liquid is deionized water, and the flow rate is 2mL / min; the coagulation bath is deionized water, and the water temperature is 20~30°C, and the attapulgite / polyvinylidene fluoride nanocomposite hollow fiber ultrafiltration membrane. Under the conditions of different nano-attapulgite additions, the membrane performance data are shown in the table below:

[0055]

[0056] It can be seen from the table that controlling the addition of na...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com