Anti-scale agent used for barium, strontium and iron and preparation method thereof

A technology of scale inhibitor and barium strontium iron, which is applied in the field of oilfield scale remover, can solve the problems such as the large rise of Luohe water pressure, the decrease of water injection volume of water injection wells, and the single scale inhibition effect, etc., and achieves simple synthesis process, high input and output. High ratio, good effect of medicine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

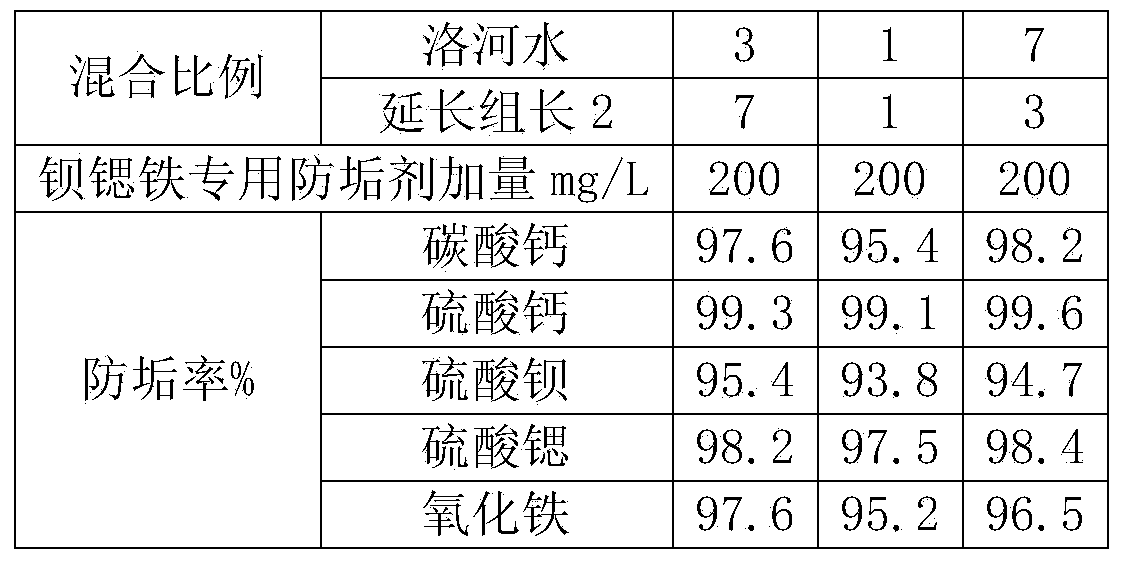

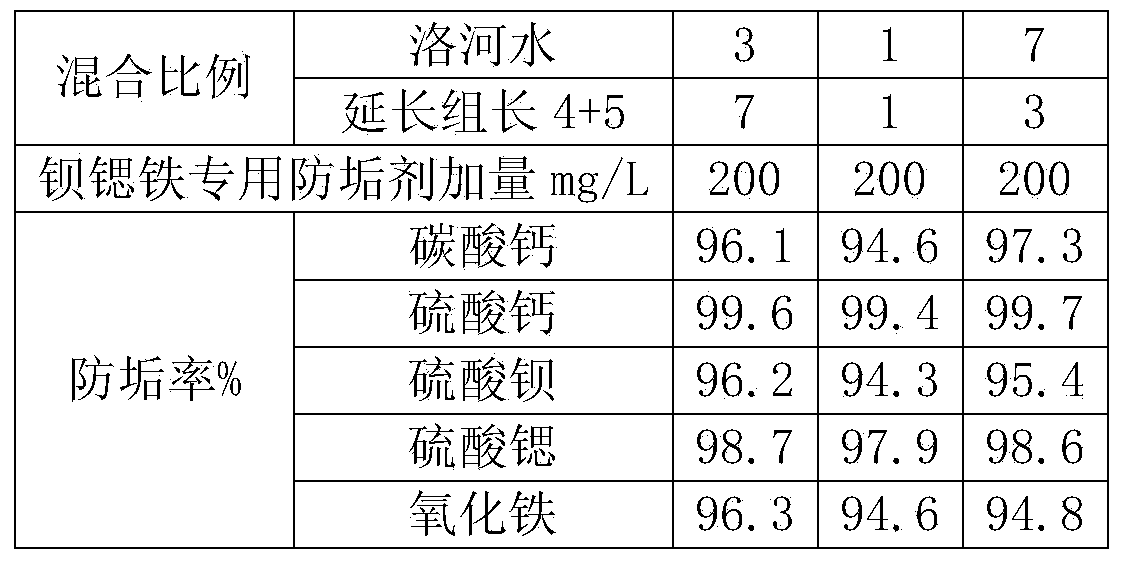

Embodiment 1

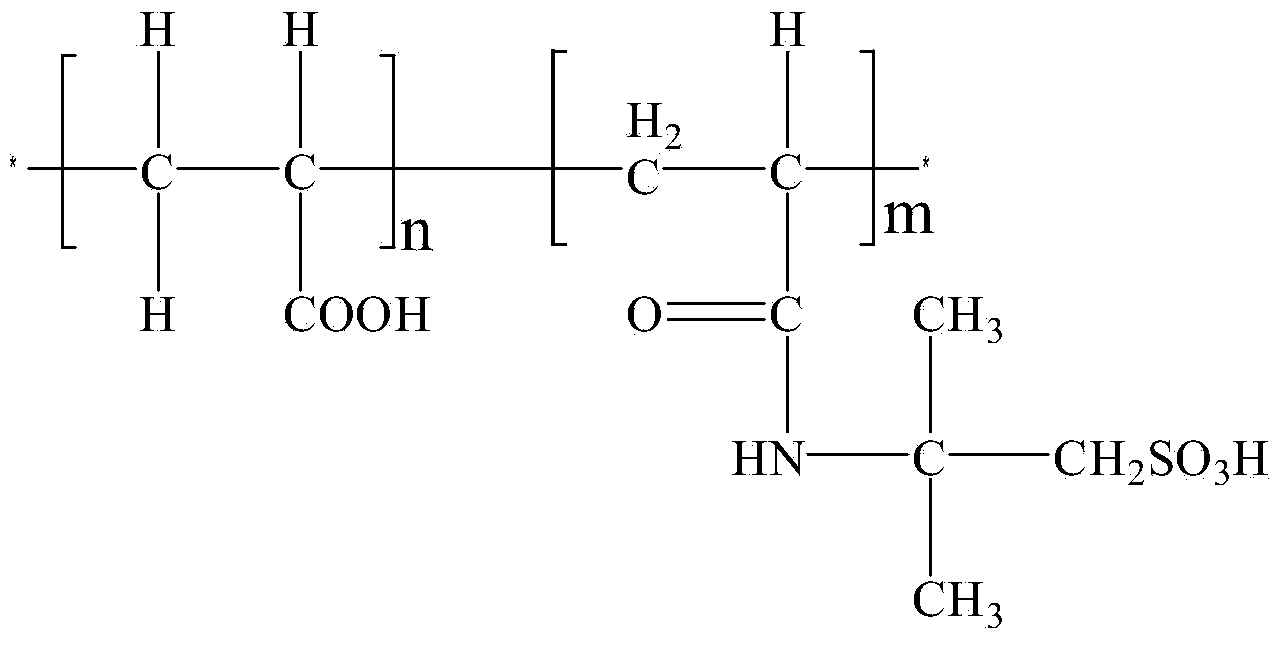

[0045] Formula composition: Dihexene triamine, nitrilotriacetic acid, formaldehyde, phosphorus trichloride synthetic derivative 45%, ethylenediaminetetraacetic acid 7%, acrylic acid and 2-acrylamide-2-methylpropanesulfonic acid synthesis 17%, the pH value is adjusted to 7.5 with ammonia water, and the rest is water.

[0046] Wherein dipenetriamine, nitrilotriacetic acid, formaldehyde, the synthesis process method of phosphorus trichloride synthetic derivative are: add a certain amount of diexenetriamine in the reaction kettle, then add nitrilotriacetic acid, under 80 ℃ Stir the reaction for 2 hours, then add a certain amount of water, control the temperature at 32-35°C, and slowly add the formaldehyde solution dropwise after stirring evenly. The temperature is controlled within 42-45°C. After the dropwise addition of formaldehyde, the temperature is raised to 100-110°C, reacted for 3 hours, and then the temperature is lowered to 35°C-40°C, slowly adding phosphorus trichloride,...

Embodiment 2

[0052] Formula composition: Dihexene triamine, nitrilotriacetic acid, formaldehyde, phosphorus trichloride synthetic derivatives 45%, ethylenediaminetetraacetic acid 6%, acrylic acid and 2-acrylamide-2-methylpropanesulfonic acid synthesis 20%, adjust the pH value to 7.3 with ammonia water, and the rest is water.

[0053] Wherein dipenetriamine, nitrilotriacetic acid, formaldehyde, the synthesis process method of phosphorus trichloride synthetic derivative are: add a certain amount of diexenetriamine in the reaction kettle, then add nitrilotriacetic acid, under 80 ℃ Stir the reaction for 2 hours, then add a certain amount of water, control the temperature at 32-35°C, and slowly add the formaldehyde solution dropwise after stirring evenly. The temperature is controlled within 42-45°C. After the dropwise addition of formaldehyde, the temperature is raised to 100-110°C, reacted for 3 hours, and then the temperature is lowered to 35°C-40°C, slowly adding phosphorus trichloride, and...

Embodiment 3

[0059] Formula composition: Dihexene triamine, nitrilotriacetic acid, formaldehyde, phosphorus trichloride synthetic derivatives 40%, ethylenediaminetetraacetic acid 8%, acrylic acid and 2-acrylamide-2-methylpropanesulfonic acid synthesis 25%, adjust the pH value to 7.5 with ammonia water, and the rest is water.

[0060] Wherein dipenetriamine, nitrilotriacetic acid, formaldehyde, the synthesis process method of phosphorus trichloride synthetic derivative are: add a certain amount of diexenetriamine in the reaction kettle, then add nitrilotriacetic acid, under 80 ℃ Stir the reaction for 2 hours, then add a certain amount of water, control the temperature at 32-35°C, and slowly add the formaldehyde solution dropwise after stirring evenly. The temperature is controlled within 42-45°C. After the dropwise addition of formaldehyde, the temperature is raised to 100-110°C, reacted for 3 hours, and then the temperature is lowered to 35°C-40°C, slowly adding phosphorus trichloride, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com