A method for treating landfill leachate concentrate by membrane method

A landfill leachate and treatment method technology, which is applied in the field of landfill leachate treatment, can solve problems such as high energy consumption, pollution transfer, and high operating costs, and achieve the effects of low energy consumption, reduced treatment costs, and low operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

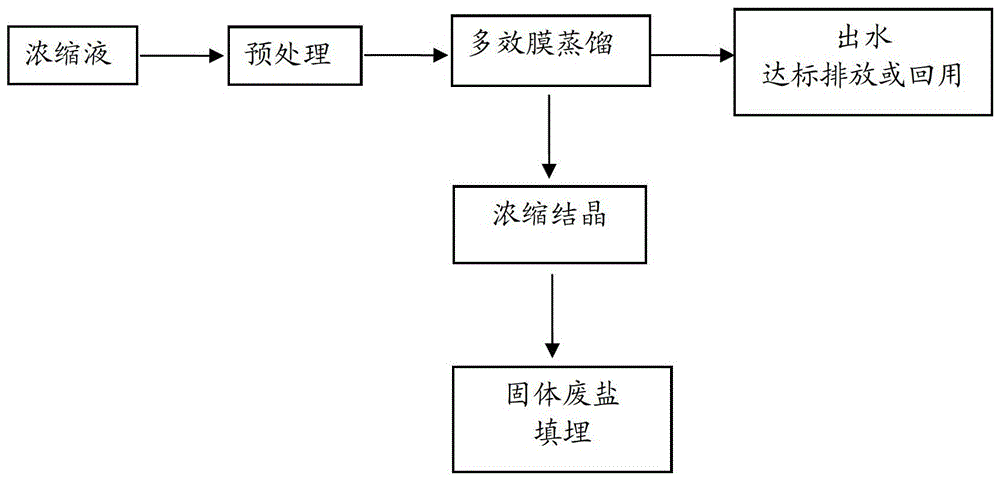

Image

Examples

Embodiment 1

[0067] After the biochemical + reverse osmosis membrane treatment of leachate from a landfill site, a membrane-based concentrated solution of about 30% of the total volume of the original landfill leachate was produced, which contained a large amount of refractory organic matter and salt. Adjust the pH value of the membrane method concentrated solution (feed solution) to 8.2, add sodium carbonate decalcification reagent to remove the calcium ions in the membrane method concentrated solution in the form of precipitates, and the removal rate of calcium ions is 92.5%; then through multi-stage Foam separation, microfiltration (average pore size is 0.1μm), ultrafiltration (cutoff molecular weight 6000MWCO) devices remove suspended matter and some refractory organic matter in the feed liquid after decalcification; then adjust the pH value of the filtrate to about 5.2 to make the solution Moderately saturated calcium salts are transformed into highly soluble calcium salts.

[0068] M...

Embodiment 2

[0073] After the biochemical + reverse osmosis membrane treatment of leachate from a landfill site, a membrane-based concentrated solution of about 30% of the total volume of the original landfill leachate was produced, which contained a large amount of refractory organic matter and salt. Adjust the pH value of the membrane concentrated solution (feed liquid) to 7.8, add sodium sulfite decalcification reagent to remove calcium ions in the membrane concentrated solution in the form of precipitates, the removal rate of calcium ions is 95%, and the feed liquid after decalcification After air bubbling oxidation, activated coke adsorption, microfiltration (average pore size: 0.1μm), ultrafiltration (cutoff molecular weight: 6000MWCO) devices, the suspended solids and some refractory organic substances in the feed liquid after decalcification are removed.

[0074] Membrane concentrated solution after pretreatment, conductivity is 63ms / cm, almost colorless, surface tension is 59mN / m, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com