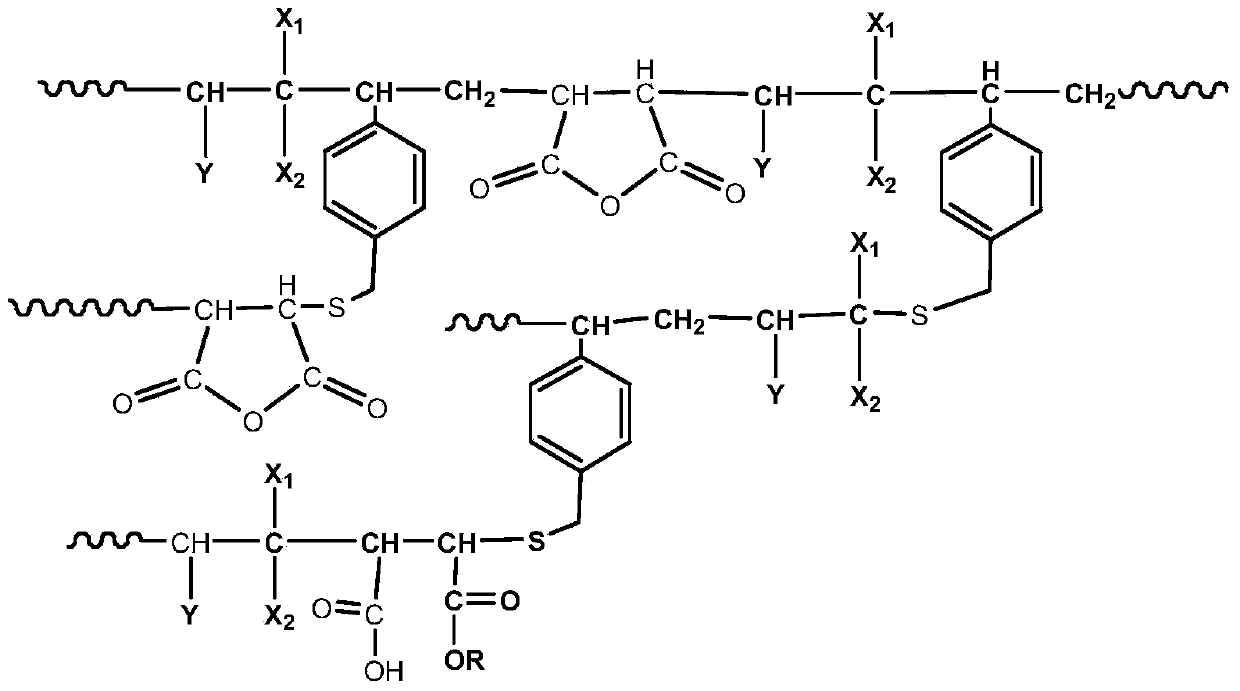

Method for improving color fastness of pigment ink by using multifunctional hyperbranched dispersant

A pigment ink, multifunctional technology, applied in dyeing method, ink, application, etc., can solve the problems of decreased stability, hard hand feeling, low color fastness of fabrics, etc., and achieve the effect of small particle size and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Dissolve the monomer 0.98g maleic anhydride, 1.04g styrene and 0.10g p-vinylbenzyl mercaptan in a beaker containing 40g toluene, stir until the solid dissolves, and then dissolve 0.23g azobisisobutyronitrile in the beaker. Stir in a beaker with 20 g of toluene until the solids are completely dissolved. Add 1 / 3 of the mixed monomer solution and the initiator solution to a 100ml four-necked flask with a condenser, stir and heat up to 65°C, and after the reaction for 30min, start to drop the remaining monomer solution and initiator solution respectively. into the reaction solution. After the dropwise addition, the reaction was continued for 24 h, and 0.2 g of p-toluenesulfonic acid and 1.6. g of methanol were added thereto, and the reaction was continued at 50° C. for 48 h. After the reaction is completed, it is cooled to room temperature, and the obtained product is suction filtered, washed with petroleum ether for 3 times and then dried to obtain a hyperbranched multifu...

Embodiment 2

[0034] Dissolve 0.75g of hyperbranched multifunctional dispersant into 44.25g of aqueous sodium hydroxide solution (pH=11), then add 5g of Pigment Red 122, adjust the pH of the system to 8-9, stir magnetically for 30min, ultrasonicate for 25min or grind to an average When the particle size is less than 200 nm, the hyperbranched dispersion C.I. Pigment Red 122 color paste is obtained, and the average particle size of the pigment particles is 170 nm.

Embodiment 3

[0036] Weigh 40g hyperbranched dispersion C.I. Pigment Red 122 color paste, then add 5g adhesive, 3g ethanol, 15g pentaerythritol, 10g ethylene glycol, 10g glycerol, 1g isopropanol, 2g Tween 20, 14g deionized The water is mixed evenly, stirred at 500 rpm for 30 minutes with a mixer, then adjusted to pH 9 with sodium hydroxide, and filtered through a 500 nm microporous membrane to obtain the pigment ink. The physical properties of this ink at 25°C are as follows: surface tension σ=30.6mN / m, viscosity η=7.88cP, Z-average particle size d=142.3nm, and Zeta potential ξ is -28.2mV. The ink was sprayed onto the fabric by an inkjet printer, and after drying, it was placed at 130° C. for 5 minutes for curing. The color fastness of the fabric was tested by a rubbing fastness tester, and its dry rubbing fastness and wet rubbing fastness were both grades 4-5. The ink has good ink jet printing fluency, bright colors, and soft handfeel of printed fabrics.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface tension | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Z-average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com