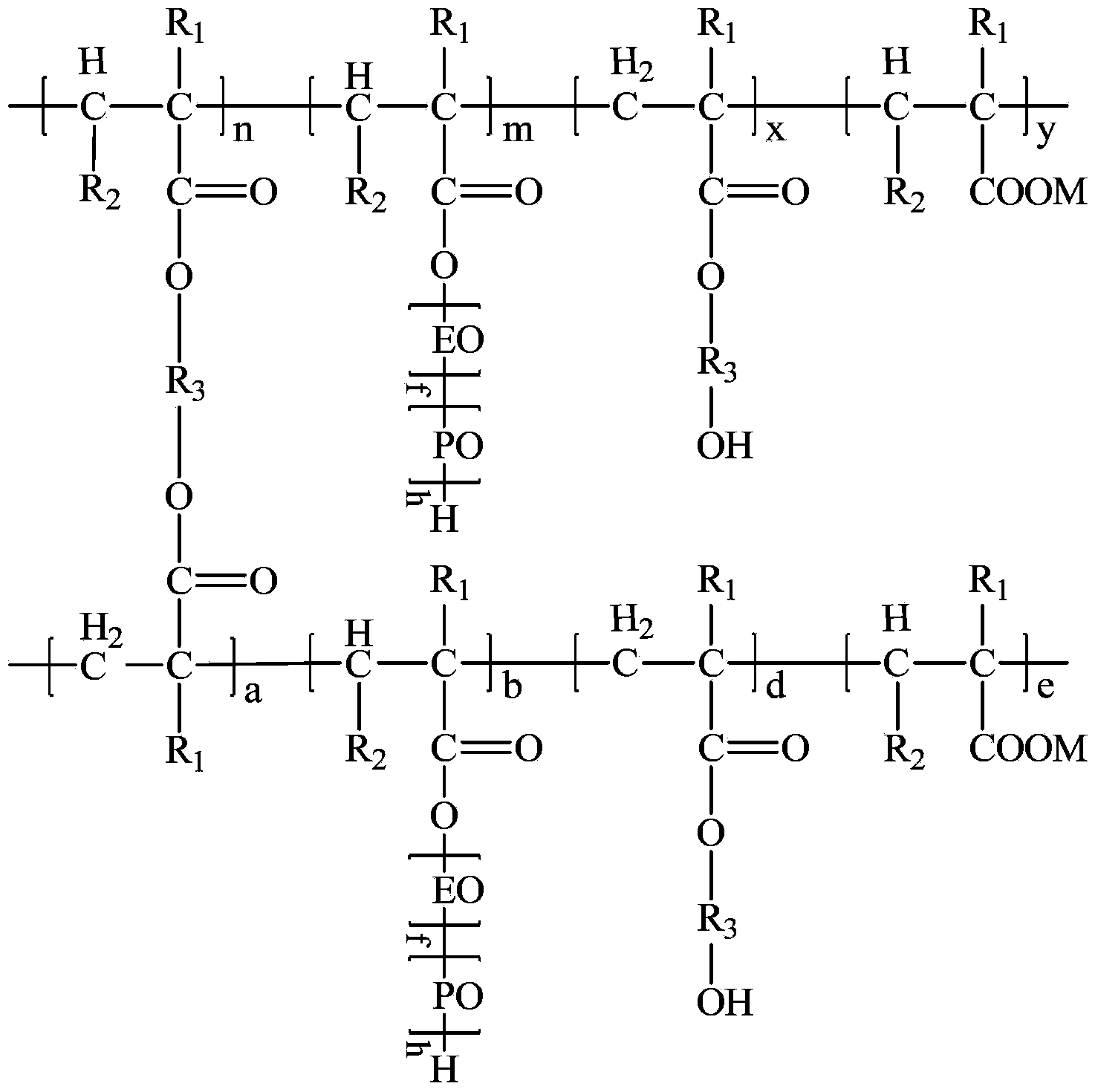

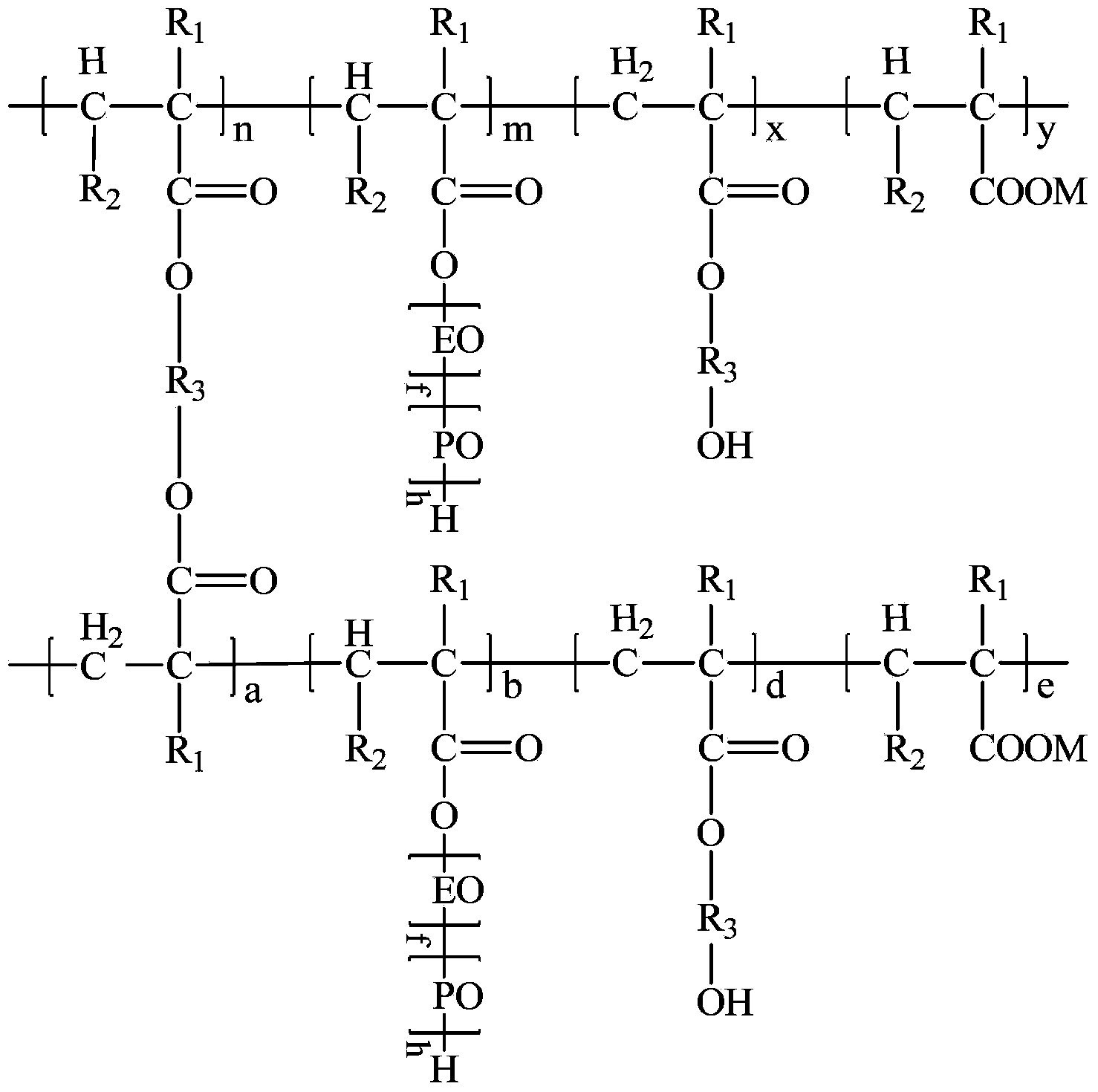

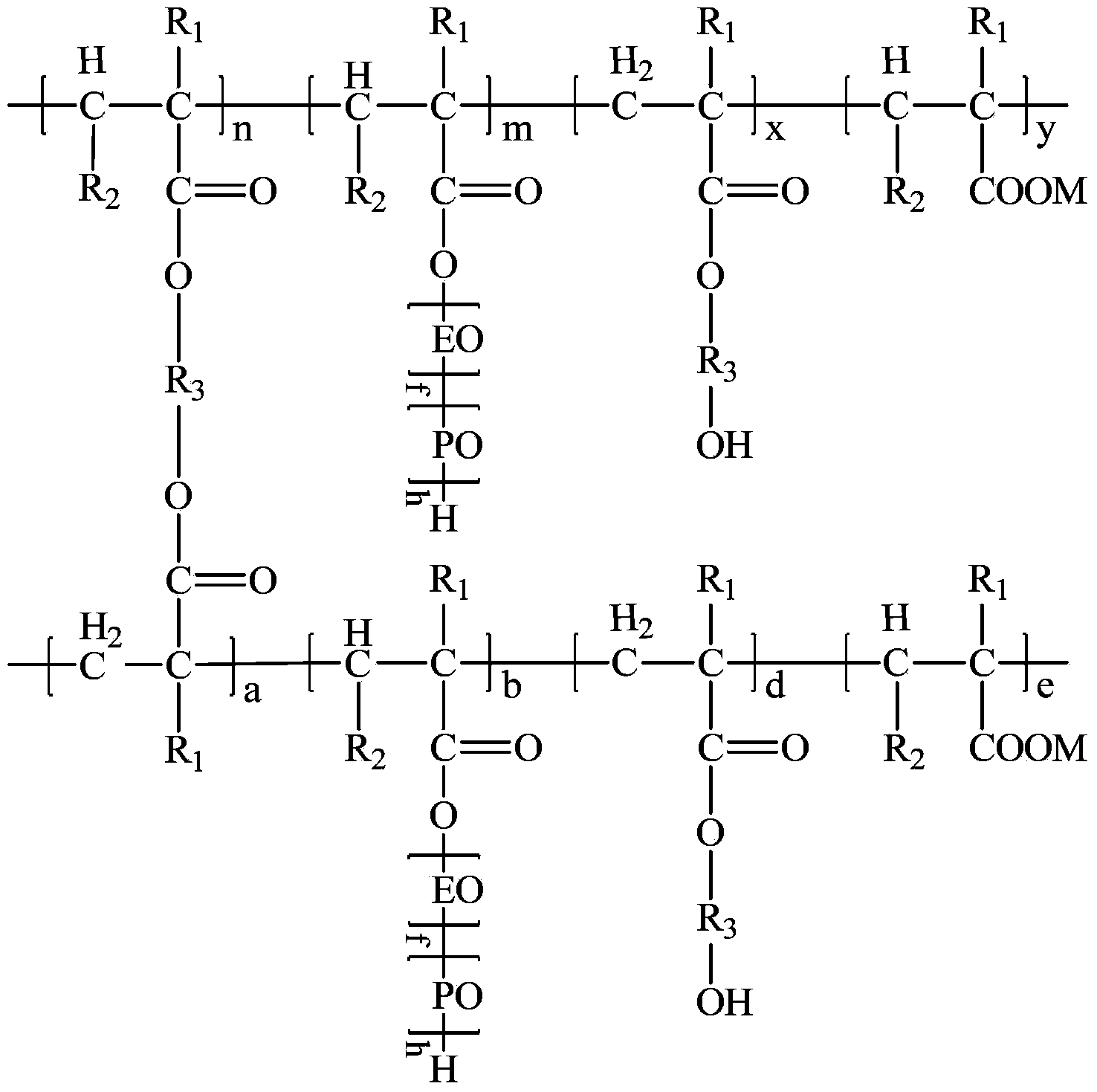

Ester polycarboxylate slump retaining agent and preparation method thereof

A technology of ester polycarboxylic acid and slump retention agent, applied in the field of building materials, can solve the problems of slump loss, uneven quality, easy bleeding, etc., to control slump loss, small steric hindrance, good adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Preparation of bifunctional monomer: Mix 72.00g of acrylic acid, 360.00g of hydroxyethyl acrylate and 11.74g of hydroquinone, under the protection of nitrogen, heat up to 60°C, add 12.07g of concentrated sulfuric acid, and heat up to 110°C , then keep the temperature for 2h, during which the water generated by the reaction is removed by the method of flowing nitrogen with water, and the temperature is lowered to room temperature after the end of the constant temperature to obtain the first mixture;

[0032] (2) Copolymerization reaction: 100.00 g of the first mixture prepared in step (1) is mixed with 69.00 g of methoxypolyethylene glycol propylene glycol acrylate with a molecular weight of 1200, and then 1.17 g of thioglycolic acid is added to obtain the second mixture, The second mixture, hydrogen peroxide aqueous solution (wherein, hydrogen peroxide 3.43g, water 20.00g) and ascorbic acid aqueous solution (wherein, ascorbic acid 0.50g, water 20.00g) were dropped in...

Embodiment 2

[0035] (1) Preparation of bifunctional monomer: Mix 86.00g of methacrylic acid, 650.00g of hydroxypropyl methacrylate and 9.88g of phenothiazine, heat up to 60°C under nitrogen protection, and add 4.52g of p-toluenesulfonic acid , the temperature was raised to 120°C, and the temperature was kept constant for 2 hours. During this period, the water generated by the reaction was removed by vacuuming, and after the constant temperature was completed, it was lowered to room temperature to obtain the first mixture;

[0036](2) Copolymerization reaction: 150.00 g of the first mixture prepared in step (1) is mixed with 120.00 g of methoxypolyethylene glycol propylene glycol acrylate with a molecular weight of 2000, and then 1.12 g of trisodium phosphate is added to obtain the second mixture , drop the second mixture and ammonium persulfate aqueous solution (ammonium persulfate 2.62g, water 40.00g) into 184.71g of water for reaction, keep the reaction temperature at 70°C, and the time f...

Embodiment 3

[0039] (1) Preparation of bifunctional monomer: Mix 49.00g maleic anhydride, 36.00g acrylic acid, 260.00g hydroxypropyl methacrylate, 116.00g hydroxyethyl acrylate, 4.00g hydroquinone and 2.00g phenothiazine , under the protection of nitrogen, the temperature was raised to 50°C, 3.48g of p-toluenesulfonic acid was added, the temperature was raised to 115°C, and the temperature was kept constant for 3 hours. mixture;

[0040] (2) Copolymerization reaction: 150.00 g of the first mixture prepared in step (1) is mixed with 160.00 g of methoxypolyethylene glycol maleate with a molecular weight of 1200, and then 1.30 g of mercaptopropionic acid is added to obtain the second Mixture, the second mixture and potassium persulfate aqueous solution (among them, potassium persulfate 2.50g, water 40.00g) were dropped into 191.72g of water for reaction, keeping the reaction temperature at 60°C, and the dropwise addition time was 3.5 hours, and the dropwise addition was completed After incub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com