Microbial displaced fluid circulation and ground fermentation method and device

A microbial oil displacement and fluid production technology, which is applied in the direction of earthwork drilling, production fluid, wellbore/well components, etc., can solve the problem of supplementing nutrients and bacteria when nutrients are inappropriate, so as to reduce production costs and improve production efficiency. Bacterial concentration, easy operation and management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

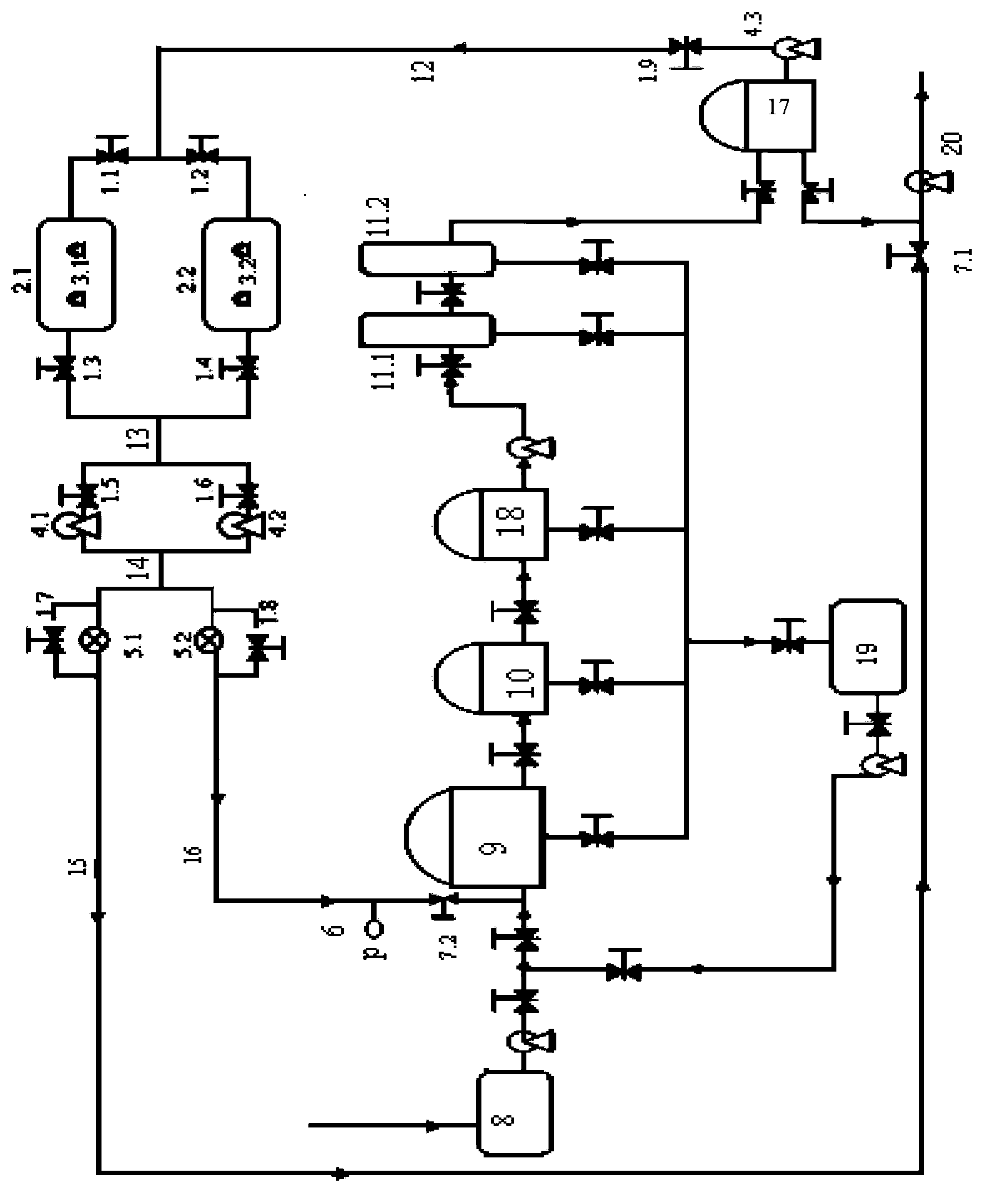

[0029] The volume of the liquid distribution tank in the process flow is 25m 3 , the motor connected to the agitator in each liquid distribution tank is a three-phase asynchronous motor; the water control valve is a flange medium pressure valve with a nominal diameter of 50mm; the flowmeter adopts an electromagnetic flowmeter with a range of 0.125 to 6000m 3 / h; the pipeline is a PVC pipeline, with an inner diameter of 50mm, a back wall of 5mm, and a pressure of 5MPa;

[0030] The incoming water for microbial flooding and dispensing comes out of the sewage storage tank 17, passes through the main liquid inlet valve 1.9 and the liquid inlet pump 4.3 along the liquid distribution water pipeline 12, and enters the liquid distribution tank A2 through the water control valve A1.1 and the water control valve B1.2 .1 and dosing pool B2.2, according to the concentration of added nutrient solution, configure nutrient solution in dosing pool A2.1 and dosing pool B2.2; stir evenly with a...

Embodiment 2

[0032] Example 2 Microbial flooding production fluid circulation and surface fermentation method

[0033] Taking Baolige oilfield sewage reinjection system as an example, the oil well output fluid in this oilfield is separated from oil and water in the three-line separator, the dehydrated crude oil is exported, and the sewage is passed through the sewage settling tank, the secondary settling tank, the buffer tank, and the filtration tank. tank, secondary filter tank, and sewage storage tank to remove residual oil and suspended matter and reinject into the two fault blocks of the oil field. The whole sewage treatment time is 8-12h, the main residence time is in the sewage settling tank, and the treatment temperature is 45℃~50℃.

[0034] Before the implementation, the device process (embodiment 1) designed by the present invention is installed in parallel on the sewage treatment process of the combined station:

[0035] Liquid distribution system: liquid distribution pool volum...

Embodiment 3

[0047] Embodiment 3 indoor physical model experiment:

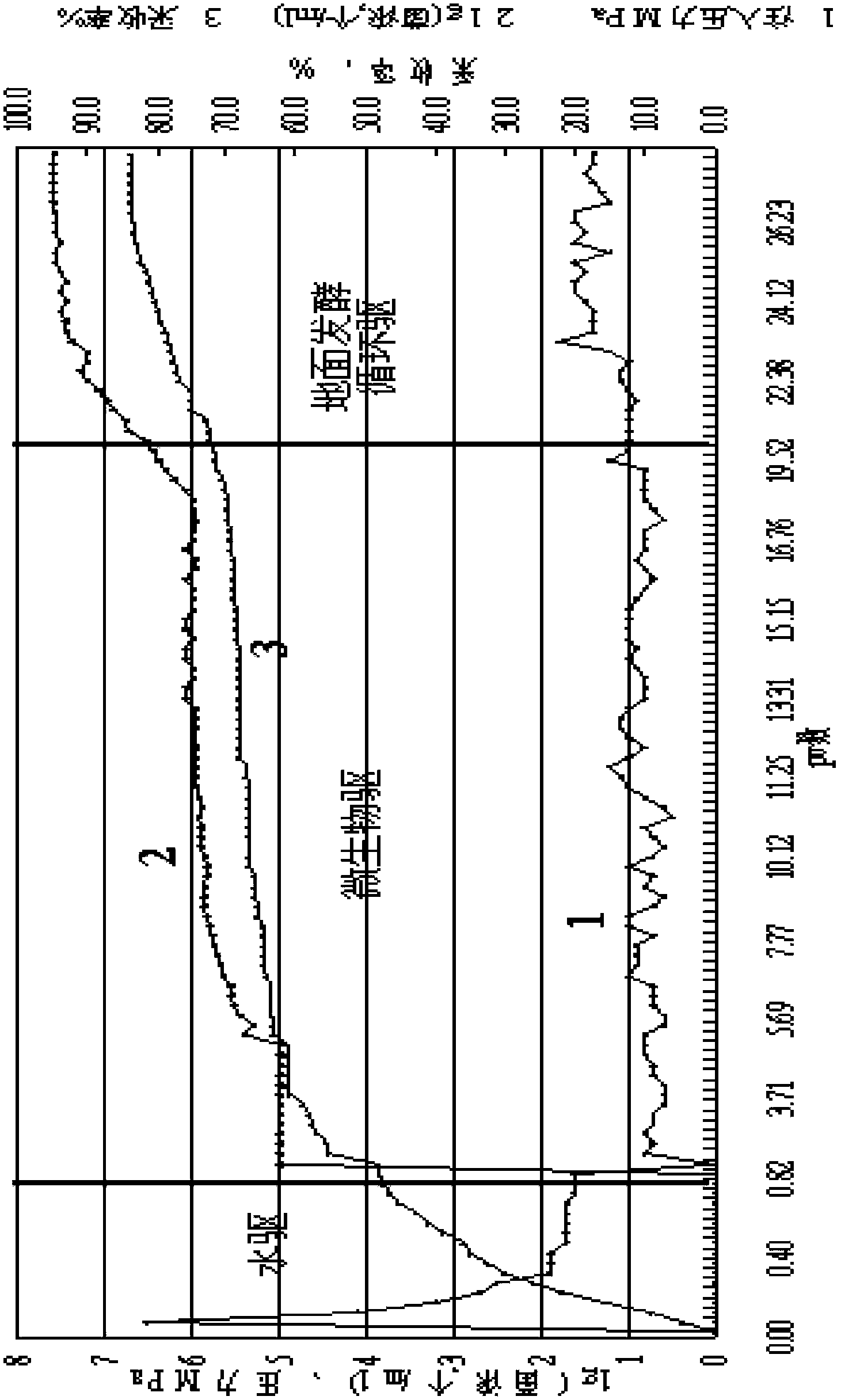

[0048] Artificial quartz sand filled core Φ2.5×100cm (core permeability 43.5×10 -3 μm 2 , porosity 31.8%, displacement pressure: 0.2~5.8MPa, displacement speed: 0.2ml / min).

[0049] The first is to establish a microbial field. After the oil-saturated core is cultivated in a 58°C constant temperature box for water flooding (formation water) to 85% water content, the bacterial solution and nutrient solution are injected to carry out microbial oil displacement, and the output is detected during the microbial displacement process. The bacterial concentration of the liquid and the change data of the recovery factor were collected, and the microbial flooding was stopped until the bacterial concentration of the produced liquid was stable, and the microbial field had been established in the formation at this time.

[0050] Secondly, carry out the simulation experiment of the surface fermentation process of microbial output liqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com