Method for improving light extraction efficiency of light-emitting diode by means of nanoindentations

A technology of light-emitting diodes and light extraction efficiency, which is applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problems of long processing time, high use cost, and limited improvement of light extraction efficiency, so as to facilitate large-scale manufacturing and economical use Guaranteed effect on cost and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A method for improving the light extraction efficiency of a light-emitting diode by using nano-indentation, the method comprising:

[0048] Using the nano-scale patterned sapphire substrate as a template, by applying a load to the nano-scale patterned sapphire substrate and the light-emitting diode epitaxial wafer, under the action of the external force of the load, the nano-scale patterned structure on the sapphire substrate acts as an indenter. into the gallium phosphide window layer of the light emitting diode epitaxial wafer, and obtain a periodic nanoscale patterned indentation structure on the gallium phosphide window layer of the light emitting diode epitaxial wafer. The light extraction efficiency of the light emitting diode is thus increased.

Embodiment 2

[0050] A method for improving the light extraction efficiency of light-emitting diodes by using nano-indentation as described in Example 1, including the following specific steps:

[0051] ① Ultrasonic cleaning of nanoscale patterned sapphire substrate and LED epitaxial wafer to ensure their respective surfaces are clean;

[0052] ②Using the nano-scale patterned sapphire substrate as a nano-indentation template, attaching the side of the sapphire substrate with a nano-scale patterned structure to the upper surface of the light-emitting diode epitaxial wafer;

[0053] ③ Applying pressure to the nano-scale patterned sapphire substrate and the light-emitting diode epitaxial wafer, the direction of the loading pressure is the direction perpendicular to the surface of the light-emitting diode, so that the nano-scale patterned structure on the surface of the sapphire substrate acts as an indenter Pressing into the light-emitting diode epitaxial wafer, forming a nano-scale patterned ...

Embodiment 3

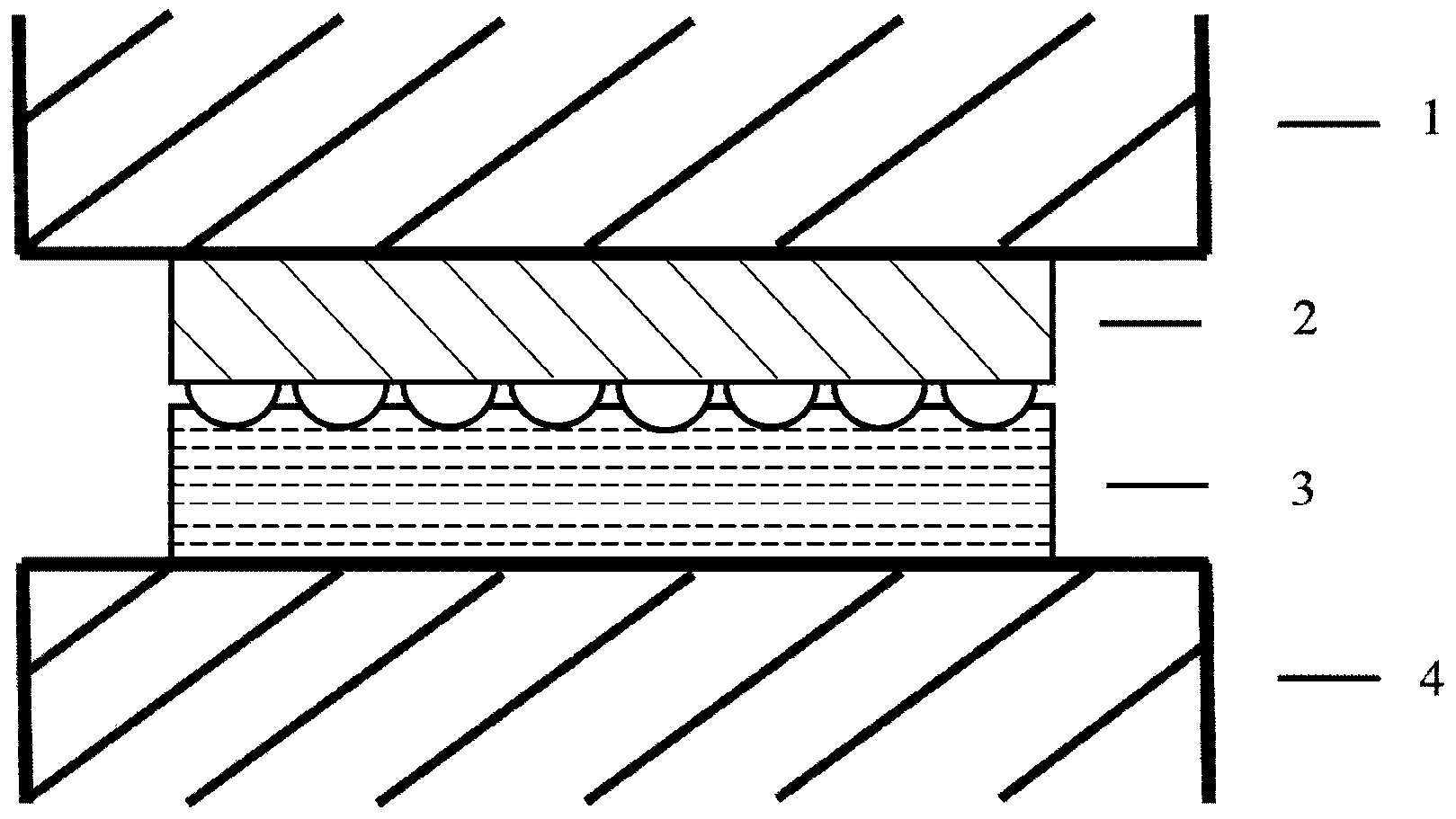

[0056] Such as Figure 1-Figure 4 shown.

[0057] Using the method described in Examples 1 and 2 to carry out nano-indentation treatment on the AlGaInP red light-emitting diode epitaxial wafer, the steps are as follows:

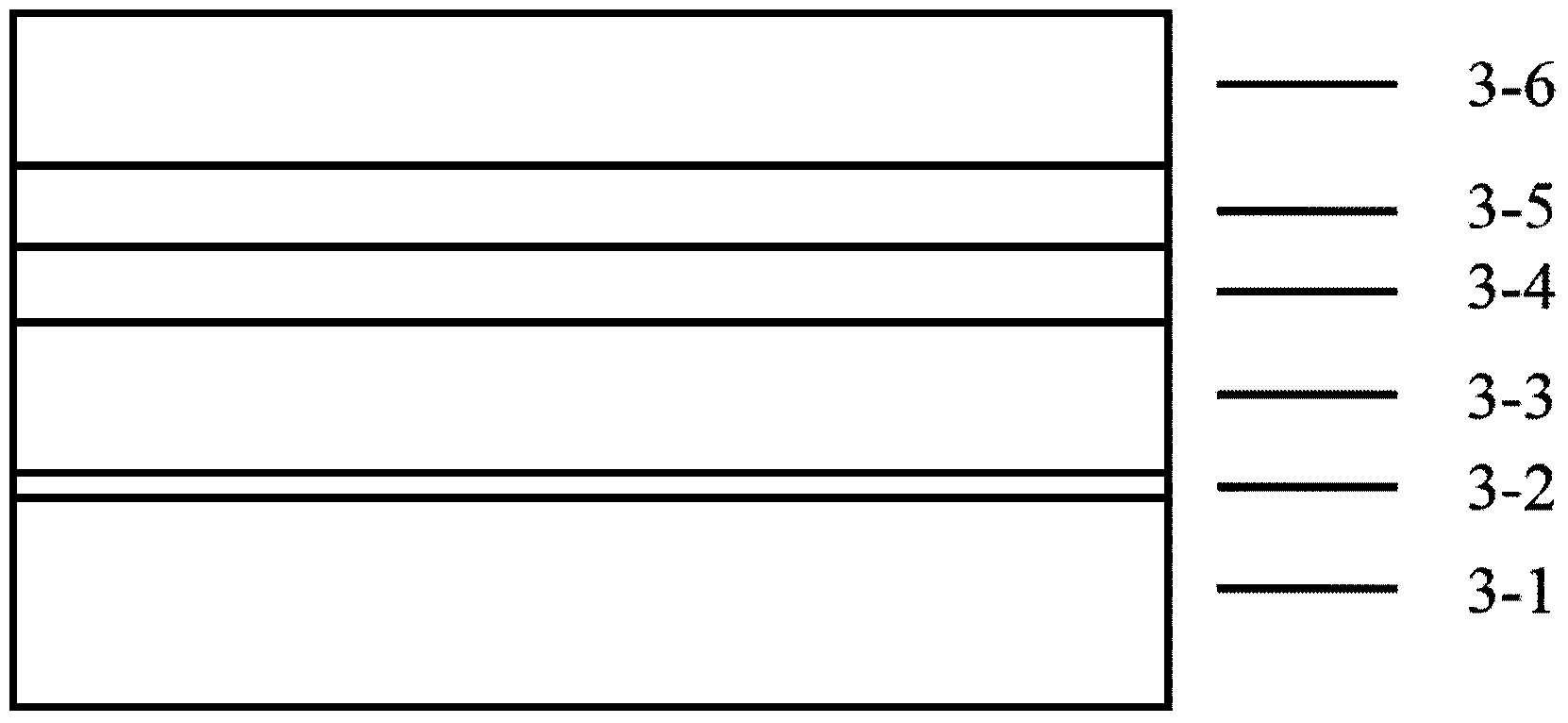

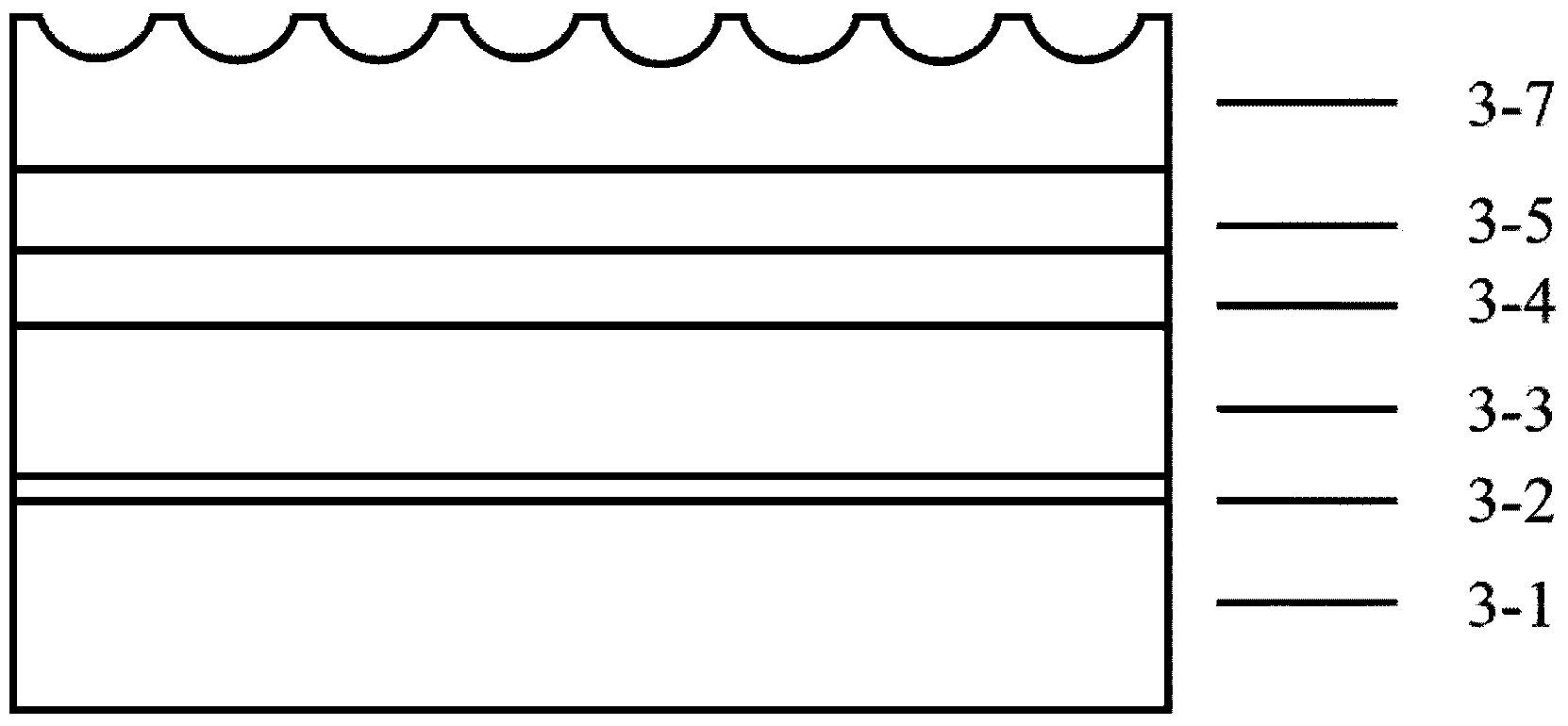

[0058] (1) Growth of red light-emitting diode epitaxial wafers: Bragg reflector 3-2, n-type aluminum gallium indium phosphorus layer 3-3, and multiple quantum wells are sequentially grown on the surface of GaAs substrate 3-1 by metalorganic chemical vapor deposition Layer 3-4, p-type aluminum gallium indium phosphide layer 3-5 and p-type GaP layer 3-6 are prepared into a red light emitting diode epitaxial wafer;

[0059] (2) Preparation of nanoscale patterned sapphire substrate 2: form a mask layer on the surface of the sapphire substrate, pattern the mask layer, and use ICP etching to obtain a hemispherical patterned structure on the surface of the sapphire substrate;

[0060] (3) Utilizing the nanoscale patterned sapphire substrate in step (2) as a nano-i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Young's modulus | aaaaa | aaaaa |

| Young's modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com