Recombined nutritional rice flakes and preparation method thereof

A technology of rice flakes and nutrition, which is applied in the field of grain processing and can solve problems affecting the development and application of sorghum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

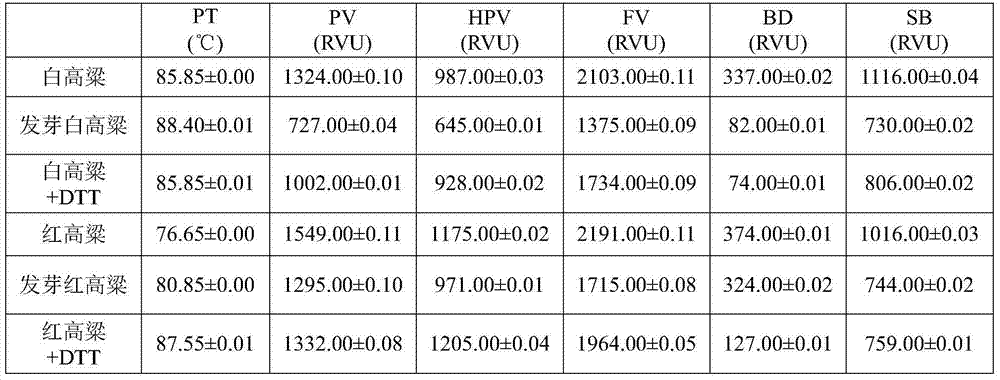

Method used

Image

Examples

Embodiment 1

[0034] The germinated white sorghum, indica rice and grain amaranth are respectively cleaned, screened, and ground into powder, and then passed through a 60-mesh sieve. Germinated white sorghum flour, rice flour, and grain amaranth powder are mixed into mixed flour in a ratio of 2:6:2, and the moisture content of the mixed flour is adjusted to 15%, and then extruded into recombined nutritional rice with a twin-screw extruder. The feeding speed is 15kg / h, the screw speed is 160r / min, the die head temperature is 70°C, the die head pressure is 3MPa, the torque is 72%, and the temperature distribution in the barrel is 75°C, 180°C, 50°C. Then dry it with hot air at 45° C. for 20 minutes, and press it into tablets with a tablet machine with a roller pitch of 0.1 mm. After being pressed, it is dried at 60° C. until the moisture content is 3%, and the germinated white sorghum, rice, and grain amaranth recombined nutritional rice flakes are obtained. The protein content of the recombi...

Embodiment 2

[0036] The germinated red sorghum, indica rice and grain amaranth are respectively cleaned, screened, and ground into powder, and then passed through a 100-mesh sieve after grinding. Germinated white sorghum flour, rice flour, and grain amaranth powder are mixed into mixed powder in a ratio of 1:8:1, and the moisture content of the mixed powder is adjusted to 30%, and then extruded into recombined nutritional rice with a twin-screw extruder. The feeding speed is 20kg / h, the screw speed is 200r / min, the die head temperature is 100°C, the die head pressure is 8MPa, the torque is 63%, and the temperature distribution in the barrel is 65°C, 140°C, 30°C. Then dry it with hot air at 55° C. for 30 minutes, and compress it with a tablet machine with a roller pitch of 0.3 mm. After being pressed, it is dried at 80°C until the water content is 6%, and the germinated red sorghum and grain amaranth recombined nutritional rice flakes are obtained. The protein content of the recombinant nu...

Embodiment 3

[0038]The germinated red sorghum, indica rice and grain amaranth are respectively cleaned, screened, and ground into powder, and then passed through a 100-mesh sieve after grinding. Germinated white sorghum flour, germinated red sorghum flour, rice flour, and grain amaranth flour are mixed in a ratio of 1:2:6:1 to form a mixed powder, and the moisture content of the mixed powder is adjusted to 20%, and extruded with a twin-screw extruder to form Reconstituted nutritional rice, the extrusion conditions are feeding speed 18kg / h, screw speed 180r / min, die head temperature 80°C, die head pressure 6MPa, torque 70%, temperature distribution in the barrel 70°C, 150 ℃, 40℃. Then 55 DEG C of hot air drying for 30 minutes, tableting with a tablet machine, the distance between the rollers of the tablet machine is 0.2 mm. After being pressed, it is dried at 70 DEG C until the water content is 5%, to obtain germinated white sorghum, germinated red sorghum, rice and grain amaranth recombin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com