Pearl enzymolysis solution and preparation method thereof

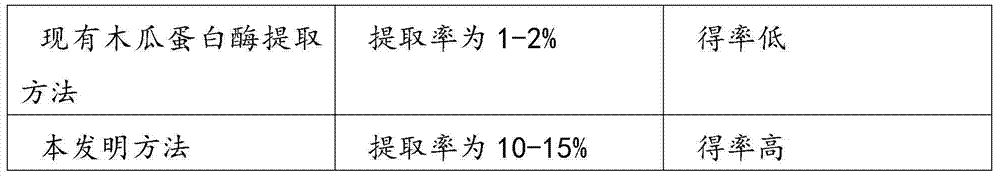

The technology of pearl enzymolysis solution and enzymolysis solution is applied in the field of biological enzymolysis, which can solve the problems of large molecular weight of polypeptide fragments and incomplete enzymolysis, and achieve the effects of high enzymolysis rate, rich variety and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

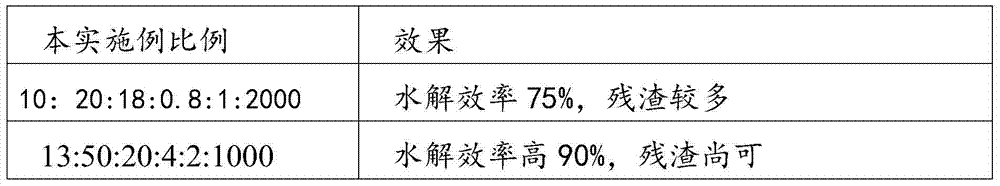

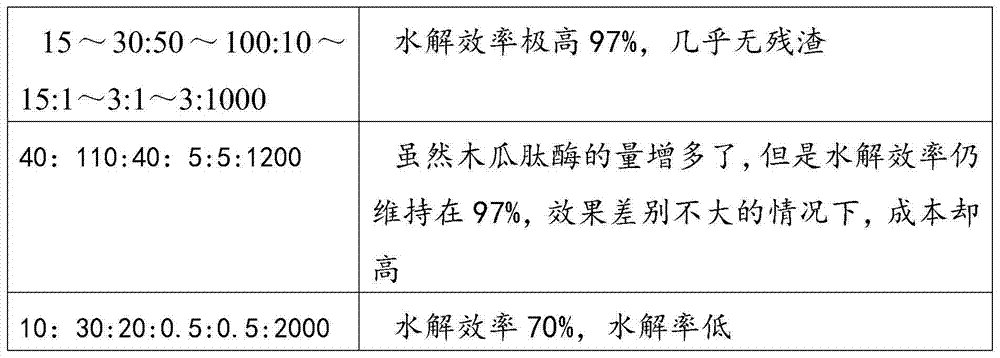

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1: a kind of pearl enzymolysis solution developed by the present invention, the raw material of this enzymolysis solution comprises pearl powder, volume concentration is 5% lactic acid solution, papaya peptidase, L-cysteine, ethylenediaminetetraacetic acid Disodium salt, distilled water, the mass ratio of the above components is 15:50:15:1:1:1000.

[0019] The raw materials taken by the present invention have no toxic and side effects, and the obtained enzymolyzed liquid has no toxicity. Drinking as a health drink and applying cosmetics to the skin has no side effects. The enzymolyzed pearl liquid is tested according to the drug toxicity test method of Shanghai Drug Inspection Institute. The acute toxicity LD50 test was carried out by intragastric administration of mice. The result is as follows:

[0020] Kunming hybrid mice, weighing 20 grams, were used and divided into male and female groups. 10 rats in each group, administered with the same dosage, and o...

Embodiment 2

[0021] Embodiment two: the raw material of pearl enzymolysis solution of the present invention comprises pearl powder, volume concentration is 10% lactic acid solution, papaya peptidase, L-cysteine, edetate disodium salt, distilled water, the above-mentioned composition The mass ratio is 30:100:10:3:3:1000

[0022] The method for preparing the above-mentioned pearl enzymatic hydrolysis solution includes the following steps, (1) preparing a lactic acid solution, the volume concentration of which is 10%;

[0023] (2) firstly add pearl powder to the lactic acid solution prepared in step (1) to carry out acidolysis reaction, centrifuge after the acidolysis reaction, the precipitate obtained is pearl shell keratin, then pearl shell keratin, papaya peptidase , L-cysteine, ethylenediaminetetraacetic acid diamine salt, and distilled water are mixed for enzymatic hydrolysis reaction. The mass ratio of sodium salt and distilled water is 30:100:10:3:3:1000, and the amino acid sequence o...

Embodiment 3

[0029] Embodiment three: the pearl enzymolysis liquid that the present invention develops, the raw material of this enzymolysis liquid comprises pearl powder, volume concentration is 7% lactic acid solution, papaya peptidase, L-cysteine, edetate disodium salt , distilled water, the mass ratio of the above components is 20:70:13:2:2:1000.

[0030] The method for preparing the above-mentioned pearl enzymatic hydrolysis solution comprises the following steps, (1) preparing a lactic acid solution, the volume concentration of which is 9%;

[0031] (2) firstly add pearl powder to the lactic acid solution prepared in step (1) to carry out acidolysis reaction, centrifuge after the acidolysis reaction, the precipitate obtained is pearl shell keratin, then pearl shell keratin, papaya peptidase , L-cysteine, ethylenediaminetetraacetic acid diamine salt, and distilled water are mixed for enzymatic hydrolysis reaction. The mass ratio of sodium salt to distilled water is 20:70:13:2:21000, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com