On-line coating preparation method and device of nano copper powder

A technology of nano copper powder and preparation device, which is applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of increased cost, large specific surface area of nano copper powder, complicated operation, etc. The effect of quality and ease of use, excellent oxidation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

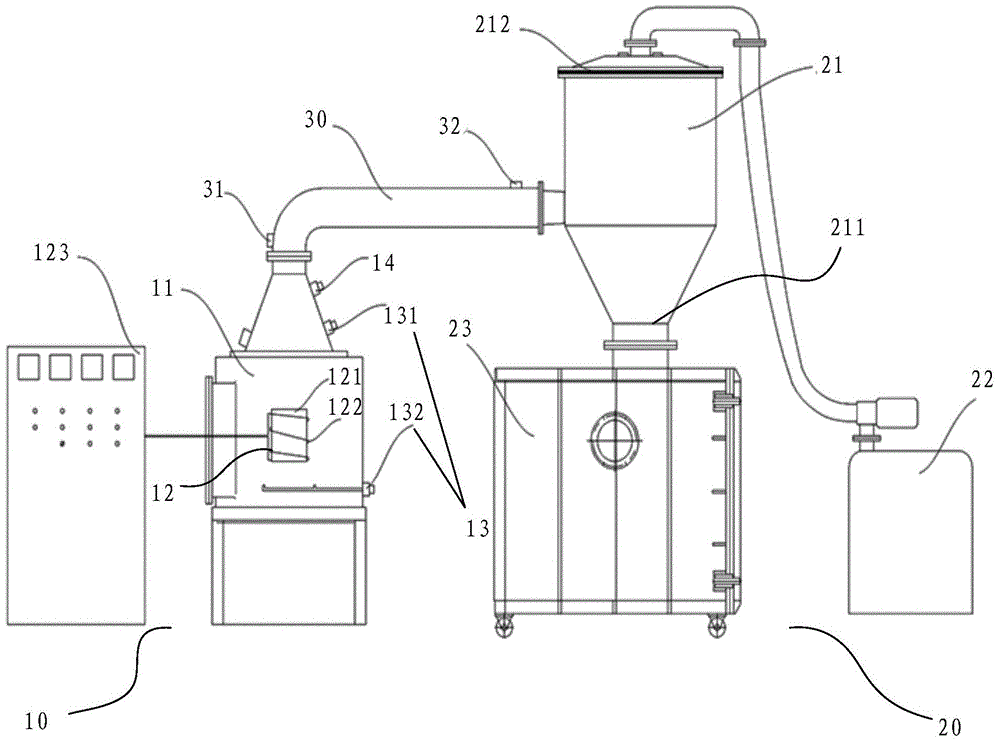

[0018] An embodiment of the present invention provides an online coating preparation method of nano-copper powder, comprising the following steps:

[0019] S10, heating, evaporating and gasifying the copper-based metal raw material in the evaporation chamber under vacuum conditions to form gaseous metal copper;

[0020] S20, during the gasification process of the copper-based metal raw material, introducing an inert gas and an aerosol coating agent into the evaporation chamber;

[0021] S30, after the copper-based metal raw material is evaporated, stop heating and continue to feed inert gas to bring the pressure in the evaporation chamber to the normal pressure level, and collect the powder after cooling to normal temperature.

[0022] Using the above steps and methods of the present invention, based on the existing heating evaporation-condensation method, metal copper can be vaporized by means of resistance heating, induction heating, plasma arc or laser; then an inert gas is...

Embodiment 1

[0039] S10, filling the high-purity oxygen-free copper wire raw material with a diameter of 4mm in the graphite crucible of the evaporation chamber;

[0040] S20, start the suction pump so that the vacuum degree of the evaporation chamber is less than 1Pa;

[0041] S30, turn on the cooling water circulation of the condensation pipe, start the super-audio frequency induction heating machine and gradually increase the power until the high-purity oxygen-free copper raw material becomes molten;

[0042] S40, to further increase the power of the super-audio frequency induction heating machine for gasification, and control the evaporation temperature between 2200 and 2600°C; at the same time, pass inert gas through the first gas inlet and the second gas inlet, Add the coating agent solution to form an aerosol coating agent, and spray the temperature at 300°C; and adjust the flow rate of the inert gas to keep the gas pressure in the evaporation chamber within the range of 1-50kPa thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com