Method for preparing nitrogen-doped graphene by treating carbonate by shock waves

A technology of nitrogen-doped graphene and carbonate, which is applied in the field of technology, can solve the problems of long reaction duration of reaction equipment, danger in the production process, and high production cost, and achieve good redox catalytic activity, low price, and high production cost. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

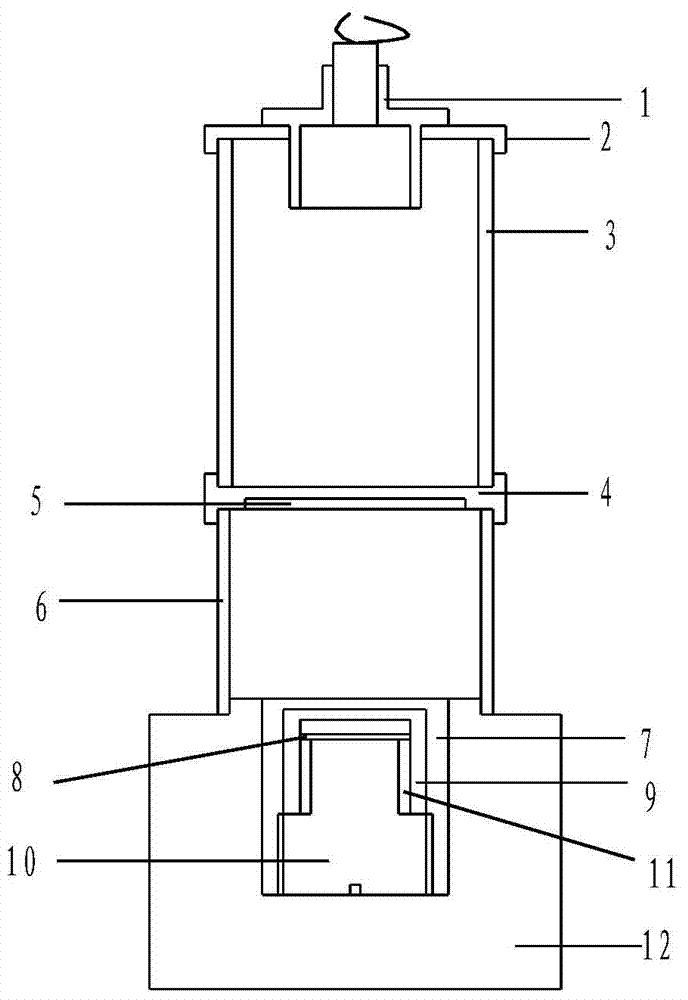

Method used

Image

Examples

Embodiment 1

[0064] (1) Mix magnesium carbonate (8g), sodium (4g) and ammonium nitrate (3.2g) evenly to obtain powder 1; put powder 1 into a copper-lined stainless steel box, and compact it with a hydraulic press to obtain the powder 1. Preform with a density of 95%;

[0065] Among them, the thickness of the copper lining is 1mm; the wall thickness of the stainless steel box is 2mm; the pressure of the hydraulic press is 7.5MPa, and the holding time is 2min;

[0066] (2) impacting the sample box with a flyer with a speed of 2.83km / s induces a chemical reaction, and obtains powder 2; wherein the flyer is a flyer driven by nitromethane liquid detonation;

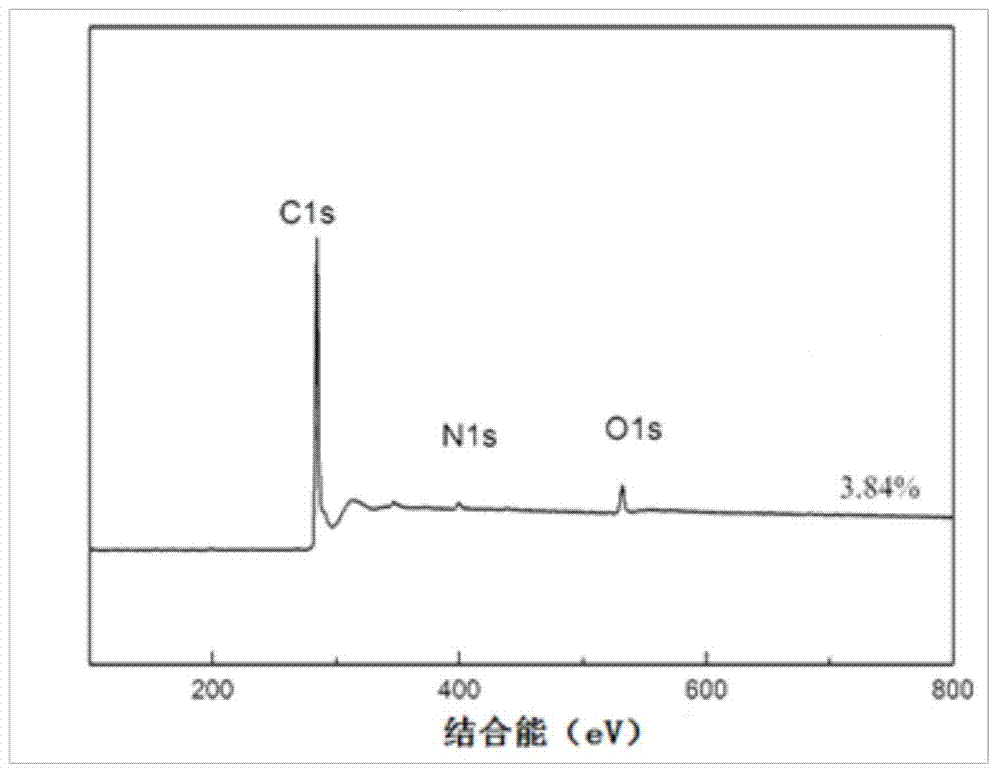

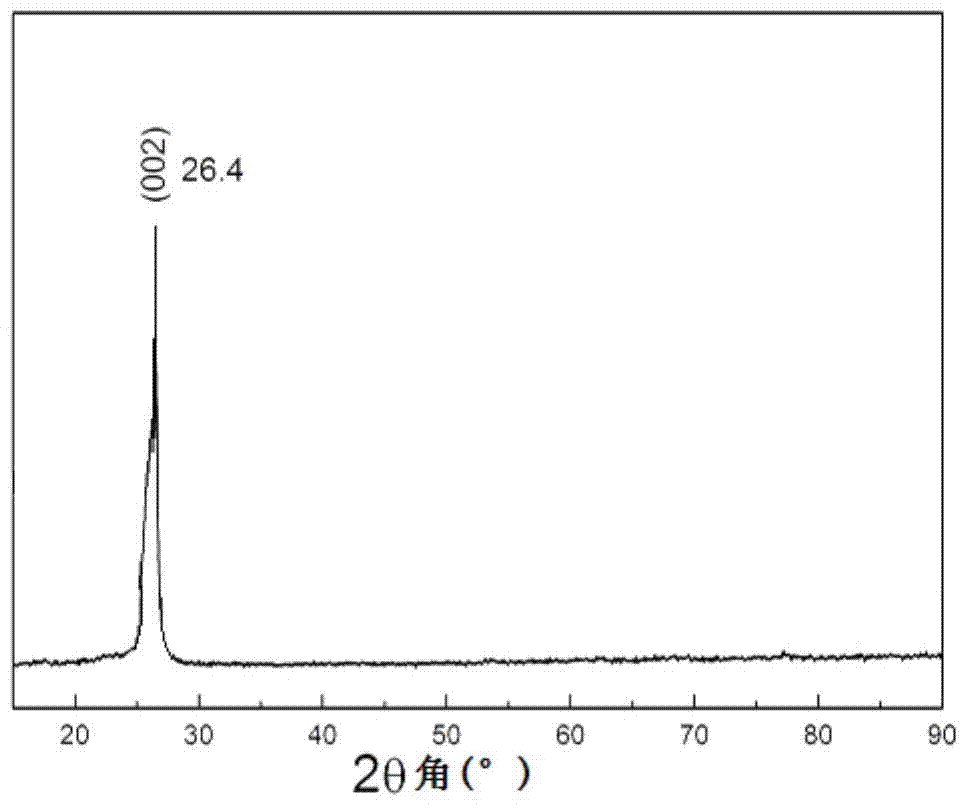

[0067] (3) Put powder 2 into the reactor, add concentrated nitric acid to purify, react at 70°C for 13h, filter and wash to obtain solid a, freeze and dry in vacuum to obtain black powder, obtained by figure 2 It can be seen that element binding energy peaks appear at 284eV, 400eV, and 532eV in the element binding energy spectrum of the ...

Embodiment 2

[0070] (1) Mix calcium carbonate (12g), sodium (3g) and ammonium nitrate (0.6g) evenly to obtain powder 1; put powder 1 into a copper-lined stainless steel box, and compact it with a hydraulic press to obtain the powder 1. A blank with a density of 80%; the thickness of the copper lining is 2mm; the wall thickness of the stainless steel box is 3mm; the pressure of the hydraulic press is 7.5MPa, and the holding time is 1min;

[0071] (2) impacting the sample box with a flyer with a speed of 2.95km / s induces a chemical reaction to obtain powder 2; wherein the flyer is a flyer driven by the detonation of nitromethane liquid;

[0072] (3) Put the powder 2 into the reactor, add concentrated nitric acid for purification, react at 65°C for 15 hours, filter and wash to obtain solid a, freeze and dry in vacuum to obtain a black powder, obtained by Figure 9 It can be seen that in the element binding energy spectrum of the black powder, element binding energy peaks appear at 284eV, 400e...

Embodiment 3

[0075] (1) Mix calcium carbonate (9g), magnesium (3g) and urea (1.8g) evenly to obtain powder 1; put powder 1 into a copper-lined stainless steel box and compact it with a hydraulic press to obtain a dense 88% of the initial billet; among them, the thickness of the copper lining is 3mm; the wall thickness of the stainless steel box is 3mm; the pressure of the hydraulic press is 7.5MPa, and the holding time is 2min;

[0076] (2) impacting the sample box with a flyer with a speed of 3.37km / s to induce a chemical reaction to obtain powder 2; wherein the flyer is a flyer driven by the detonation of a nitromethane liquid;

[0077] (3) Put the powder 2 into the reactor, add concentrated nitric acid for purification, react at 80°C for 12 hours, filter and wash with suction to obtain solid a, freeze and vacuum-dry to obtain a black powder, obtained by Figure 16 It can be seen that in the element binding energy spectrum of the black powder, element binding energy peaks appear at 284eV...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com