Production method for preparation of calcium dihydrogen phosphate and by-production of special fertilizer for cauliflowers

A technology of calcium dihydrogen phosphate and calcium hydrogen phosphate, applied in chemical instruments and methods, applications, phosphorus compounds, etc., can solve problems such as reducing the purity of calcium dihydrogen phosphate products, difficulty in meeting calcium dihydrogen phosphate, and affecting soil structure layers , to achieve the effect of promoting yield and quality of cauliflower, improving absorption rate and improving purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

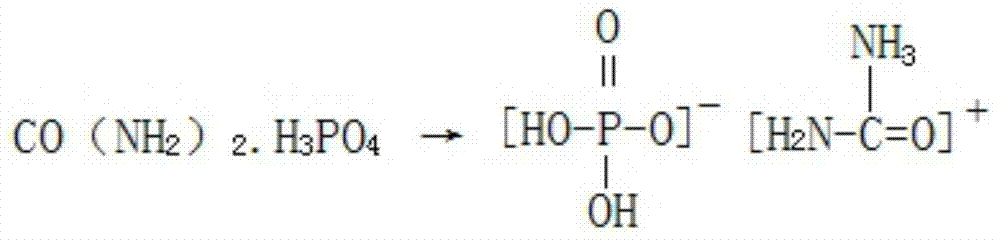

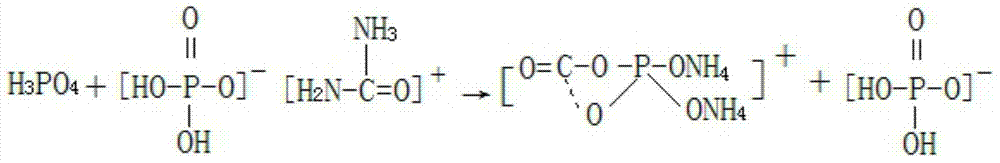

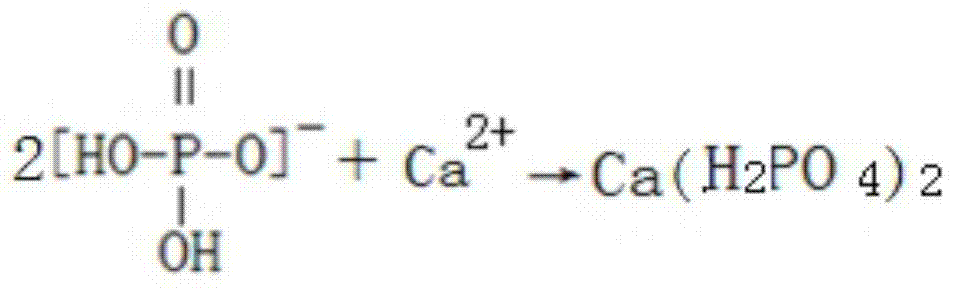

Method used

Image

Examples

Embodiment 1

[0044] A production method for preparing calcium dihydrogen phosphate by-product cauliflower special fertilizer, comprising the following steps:

[0045] (1) Preparation and mixing of raw materials: Put phosphoric acid and carbonamide at a molar ratio of 1.4:1 in a stirred reactor at a temperature of 80°C and control the stirring speed of the stirred tank at 180r / min to stir and mix for 2 hours to obtain an intermediate slurry;

[0046] (2) Preparation of calcium hydrogen phosphate: Add soluble calcium salt into the reaction kettle containing the intermediate slurry prepared in step 1) at a constant speed for 2 hours, control the pH value to 3, continue stirring and reacting for 10 minutes, and the reaction ends to obtain Slurry containing calcium hydrogen phosphate;

[0047] (3) Cyclic crystallization and filtration: place the slurry containing calcium hydrogen phosphate obtained in step 2) in a cooling crystallizer to cool down to a temperature of 20° C. within 10 seconds, ...

Embodiment 2

[0053] A production method for preparing calcium dihydrogen phosphate by-product cauliflower special fertilizer, comprising the following steps:

[0054] (1) Preparation and mixing of raw materials: Phosphoric acid and carbonamide are placed in a stirred reactor at a molar ratio of 2.0:1, at a temperature of 100°C, and the stirring speed of the stirred tank is controlled at 200r / min to stir and mix for 3 hours to obtain an intermediate slurry;

[0055] (2) Preparation of calcium hydrogen phosphate: Add soluble calcium salt 3h at a constant speed to the reaction kettle containing the intermediate slurry obtained in step 1), control the pH value to 3.5, continue stirring and reacting for 15min, and the reaction ends to obtain Slurry containing calcium hydrogen phosphate;

[0056] (3) Cyclic crystallization filtration: place the slurry containing calcium hydrogen phosphate obtained in step 2) in a cooling crystallizer to cool down to a temperature of 19°C within 10s, cool down t...

Embodiment 3

[0062] A production method for preparing calcium dihydrogen phosphate by-product cauliflower special fertilizer, comprising the following steps:

[0063] (1) Preparation and mixing of raw materials: Phosphoric acid and carbonamide are mixed in a stirred reactor at a molar ratio of 1.7:1 at a temperature of 90°C and the stirring speed of the stirred tank is controlled at 190r / min for 2.5 hours to obtain intermediate body slurry;

[0064] (2) Preparation of calcium hydrogen phosphate: Add soluble calcium salt into the reaction kettle containing the intermediate slurry obtained in step 1) at a constant speed for 2.5 hours, control the pH value to 3.3, continue stirring and reacting for 12 minutes, and the reaction ends. Obtain the slurry containing calcium hydrogen phosphate;

[0065] (3) Cyclic crystallization and filtration: the slurry containing calcium hydrogen phosphate obtained in step 2) is placed in a cooling crystallizer to cool down to a temperature of 18°C within 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com