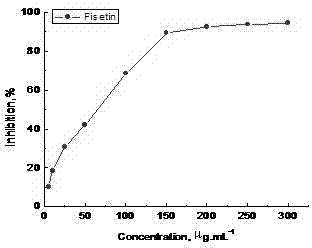

Preparation method of fisetin capable of inhibiting tyrosinase activity through rapid separation in medium-pressure column

A technology of tyrosinase and fisetinase, applied in the directions of organic active ingredients, preparations for skin care, medical preparations containing active ingredients, etc., to achieve the effect of easy implementation, high purity, prevention and treatment of chronic diseases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

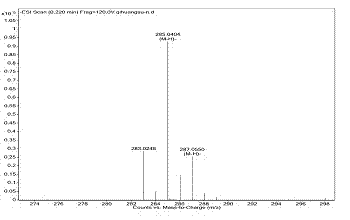

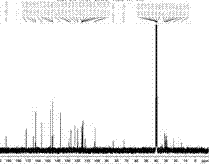

Image

Examples

Embodiment 1

[0040] Step one, degreasing:

[0041] The lacquer wood flour was dried, crushed, and degreased with petroleum ether. The volume ratio of wood powder mass and petroleum ether was 1:15 g / mL, at a temperature of 30°C, extracted for 3 h, extracted 4 times, filtered to obtain a filter residue, dried, and degreased sumac powder;

[0042] The second step, extract:

[0043] Add 1 g raw material of sumac powder to 15 mL of 50% methanol aqueous solution or ethanol aqueous solution to extract 4 times, the extraction temperature is 60 ° C, the extraction time is 1 h, after extraction, filter, combine the filtrates, and concentrate in vacuum to obtain the crude extract of sumac;

[0044] The third step, extraction:

[0045] The extract obtained from the extract was extracted 3 times with ethyl acetate organic solvent, and the ethyl acetate layer was concentrated to obtain ethyl acetate extract;

[0046] The fourth step, medium pressure column purification:

[0047] The ethyl acetate ex...

Embodiment 2

[0053] Step one, degreasing:

[0054] The lacquer wood powder was dried, crushed, and degreased with petroleum ether, diethyl ether, n-hexane, pentane, and n-pentane organic solvents. The ratio of wood flour mass to organic solvent volume was 1:35 g / mL at a temperature of 80 °C for 1 h. 1 time, filter to obtain filter residue, dry to obtain defatted sumac powder;

[0055] The second step, extract:

[0056] Add 1 g raw material of sumac powder to 30 mL of 30% methanol aqueous solution or ethanol aqueous solution to extract 1-4 times, the extraction temperature is 680 ° C, the extraction time is 3 h, after extraction, filter, combine the filtrates, and vacuum concentrate to obtain the crude extract of sumac ;

[0057] The third step, extraction:

[0058] The extract obtained from the extract is extracted twice with an ethyl acetate organic solvent, and the ethyl acetate layer is concentrated to obtain an ethyl acetate extract;

[0059] The fourth step, medium pressure column...

Embodiment 3

[0065] Step one, degreasing:

[0066] The lacquer wood powder was dried, crushed, degreased with n-hexane, the volume ratio of wood powder mass and n-hexane was 1:20 g / mL, the temperature was 60°C, extracted for 2 h, extracted twice, filtered to obtain filter residue, dried to obtain degreased sumac powder;

[0067] The second step, extract:

[0068] Add 1 g raw material of lacquer tree powder to 20 mL of methanol aqueous solution or ethanol aqueous solution of different concentrations to extract 1-4 times, the extraction temperature is 60-80°C, and the extraction time is 1-3 h. After extraction, filter, combine the filtrates, and concentrate in vacuo to obtain Sumac crude extract;

[0069] The third step, extraction:

[0070] Extracting the extract obtained from the extract with ethyl acetate organic solvent for 2-5 times, concentrating the ethyl acetate layer to obtain the ethyl acetate extract;

[0071] The fourth step, medium pressure column purification:

[0072] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com