Chromium-silicon co-infiltration agent on alloy surface and preparation method of coating

A chrome-silicon infiltration and alloy technology is applied in the field of alloy surface coating preparation. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

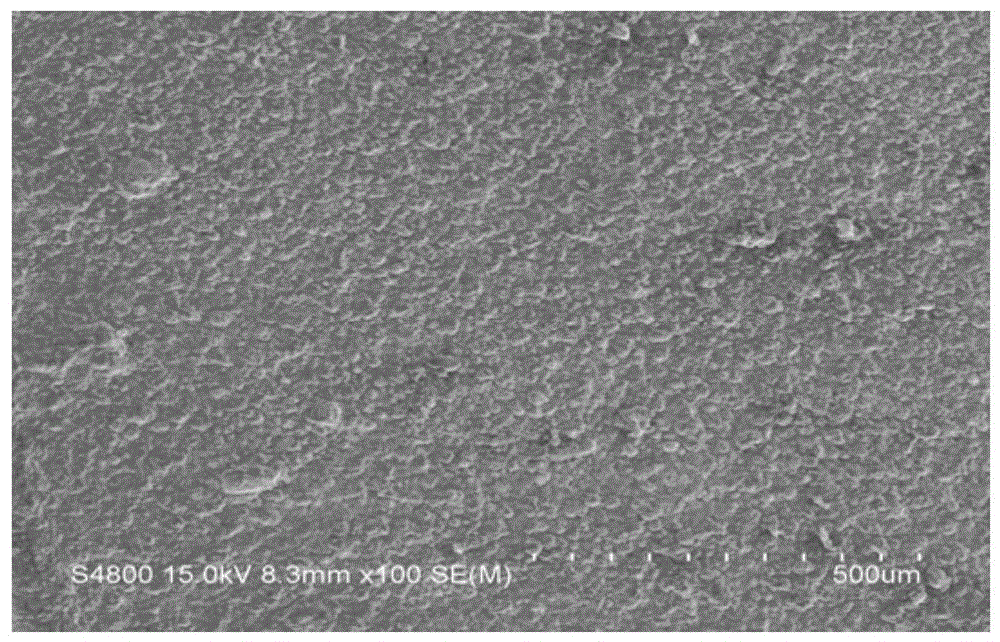

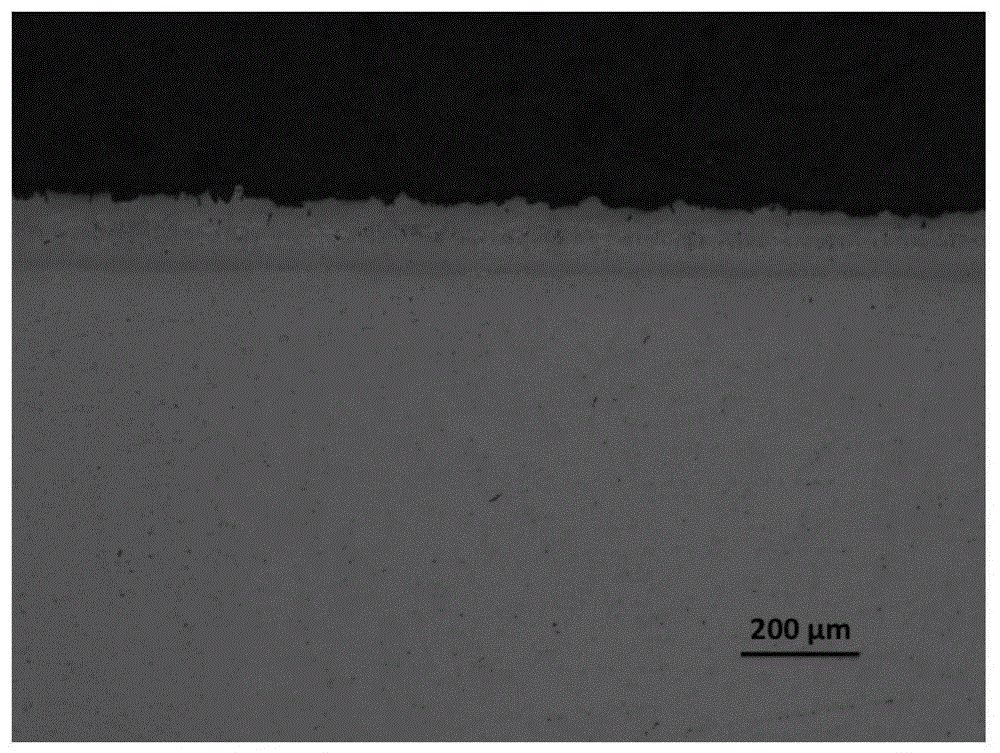

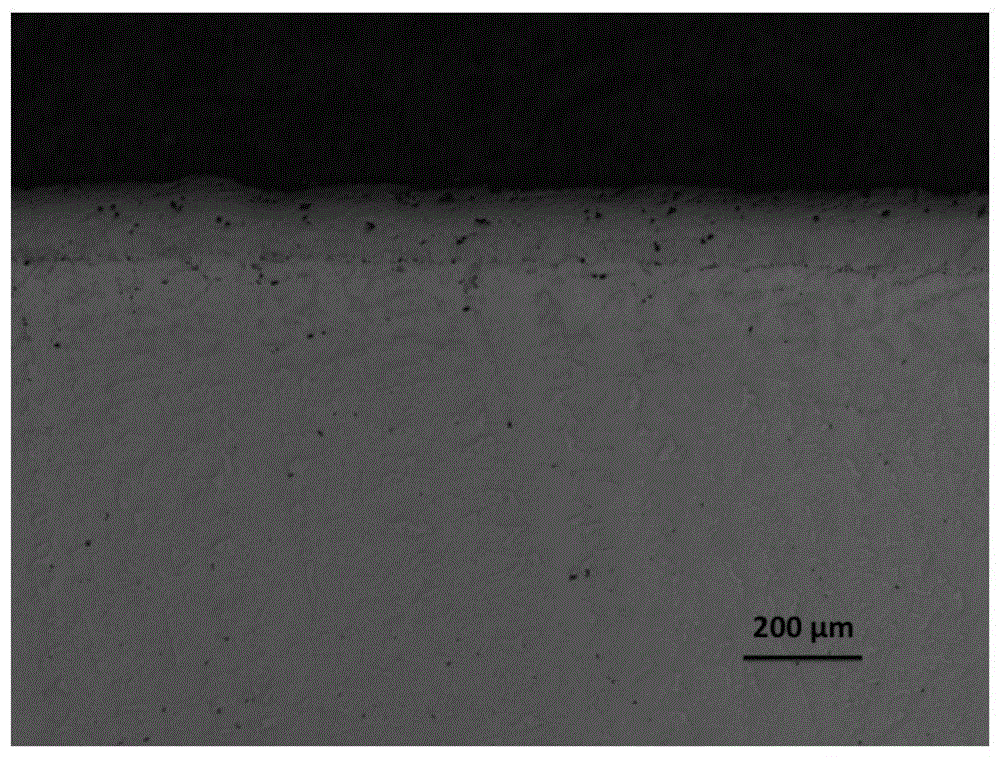

Image

Examples

Embodiment 1

[0039] A kind of alloy surface chromium-silicon infiltrating agent in the present embodiment, comprises the component powder of following percentage by weight: Chromium: 20%, ferrosilicon alloy: 15%; Titanium: 3%; Activator: 2% (ammonium chloride 0.5%, sodium fluoride 1.5%); calcium oxide: 5%; magnesium oxide: 5%; aluminum oxide: the balance. The particle size of the above-mentioned component powders is 150-250 mesh.

[0040] The workpiece material is Cr25Ni35Nb alloy, and the coating preparation process is as follows:

[0041] Step (1): calcining the alumina powder at a temperature of 1100° C. for 2 hours. Weigh each component by weight percentage, stir and mix them evenly, and put them into the infiltration box.

[0042] Step (2): Grind the workpiece with silicon carbide sandpaper to 800#, wash with acetone and blow dry.

[0043] Step (3): Embed the workpiece in the infiltrant and compact it, the distance between the workpiece and the top and bottom is 30mm. Then seal th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com