Preparation method of composite feed additive containing lipase and lactic acid bacteria

A compound feed, lipase technology, applied in the direction of animal feed, animal feed, application, etc., can solve the problems of blank and less research on the mechanism of lipase action, and achieve the purpose of reducing emissions, improving the gastrointestinal environment, improving meat quality and improving meat quality. flavor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

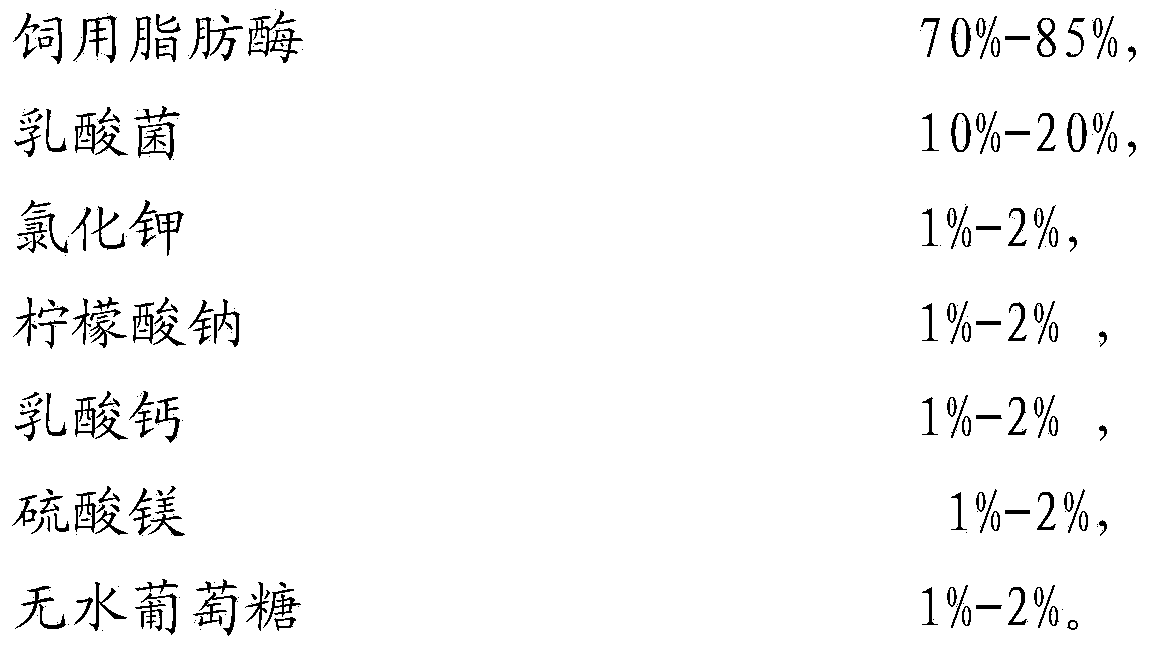

Method used

Image

Examples

Embodiment 1

[0028] Step A: extracting and preparing feed lipase with high enzyme activity. The process route of its extraction is: filter the fermented liquid with plate and frame to remove bacteria, add thiamine to precipitate the filtrate after ultrafiltration and concentration, then filter to obtain enzyme sludge, and adopt low-temperature fluidized drying and granulation technology to dry the enzyme sludge , to obtain highly active dry enzyme granules.

[0029] Among them, the lipase is fermented by Candida, and its fermentation enzyme production process and lipase extraction are: 20m 3 In the fermentation tank, the ventilation rate is 0.4-0.8V / V / min, the stirring speed is 180r / min, the fermentation temperature is 35°C, cottonseed oil and olive oil (1:1) are added during the cultivation process to control the fermentation end point, and the pH value is Under the condition of 5.5~6.5, ferment for 72h, the mature fermentation enzyme activity is 4000U / mL. The fermented liquid is filter...

Embodiment 2

[0036] Step A: Candida is used for lipase, and its fermentation enzyme production process and lipase extraction are: 20m 3 The fermentation tank has a ventilation rate of 0.4-0.8V / V / min, a stirring speed of 180r / min, and a fermentation temperature of 35°C. During the cultivation process, cottonseed oil and olive oil (1:1) are added to control the fermentation end point, and the pH value is Under the condition of 5.5~6.5, ferment for 72h, the mature fermentation enzyme activity is 4000U / mL. The fermented liquid is filtered, concentrated by ultrafiltration, precipitated by ammonium sulfate, dried and granulated to obtain the finished product of granular alkaline lipase. 4 U / g.

[0037] Step B: preparing microencapsulated complex lactobacilli, specifically including the following aspects.

[0038] The activation method of Lactobacillus is as follows: take a small amount of Lactobacillus stored at -70°C and inoculate them in MRS liquid medium respectively, culture them staticall...

Embodiment 3

[0043] 1. Animals for testing: 180 weaned piglets at the age of 21 days were randomly divided into 2 treatment groups, each of which was repeated 5 times, and 18 piglets were each repeated. The test group of the prepared premix (adding 1.0kg / T feed). Group C is the test group using the premix prepared in Example 2 (1.0 kg / T feed added).

[0044] 2. The test period is 42 days.

[0045] 3. Measuring indicators: daily weight gain; feed-to-meat ratio; diarrhea rate; death rate.

[0046] 4. The test is shown in Table 1

[0047] Table 1

[0048] indicators

Group A

Group B

Group C

Initial weight(kg)

8.36±0.82 a

8.78±0.68 a

8.85±0.65 a

Weight at the end of the test (kg)

25.33±3.21 a

26.38±3.82 a

26.58±3.67 a

Daily weight gain (kg / d)

0.404±0.06 a

0.419±0.09 a

0.424±0.08 a

material to weight ratio

1.56±0.12 a

1.50±0.15 a

1.45±0.12 a

Diarrhea rate (%)

4.55±0.66 a

2.82±0.45 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com