Imidazole functionalized magnetic meso-porous silicon as well as preparation method and application thereof

A mesoporous silicon, functionalized technology, applied in chemical instruments and methods, inorganic chemistry, radioactive purification, etc., can solve the problems of difficult recycling and reuse, achieve strong magnetic response intensity, high specific surface, and promote selective adsorption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The invention provides a method for preparing imidazole functionalized magnetic mesoporous silicon, comprising the following steps:

[0028] (1) Using magnetic iron ferric oxide nanoparticles as the core, using a sol-gel method, using a silicon source precursor to hydrolyze, and coating a layer of amorphous silicon dioxide on the surface of the magnetic iron ferric oxide nanoparticles;

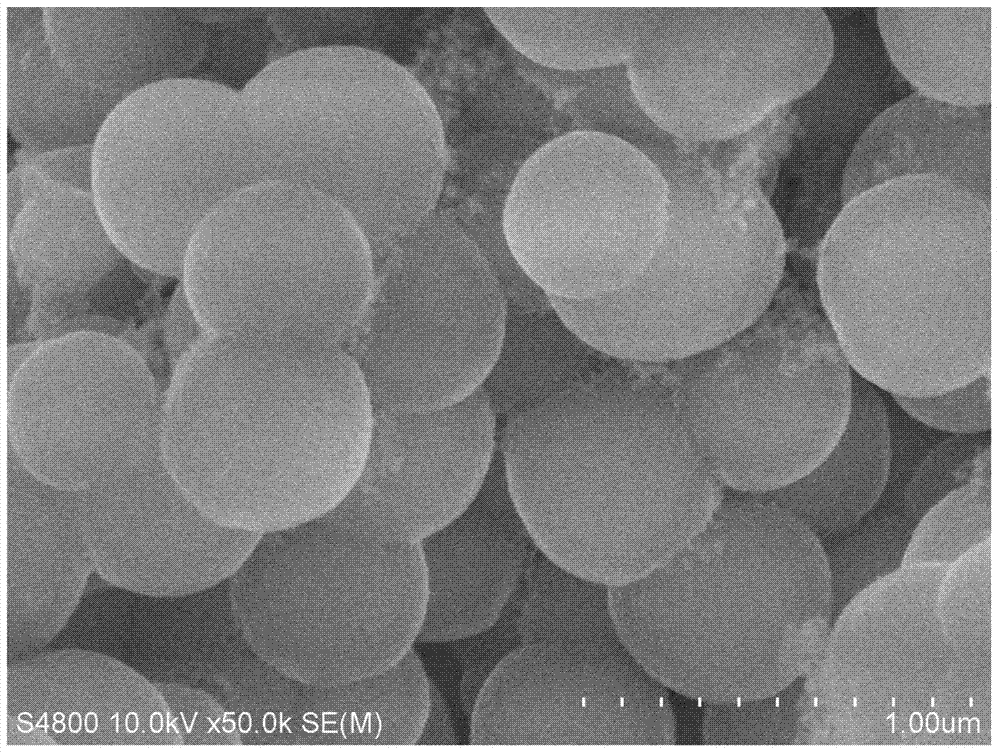

[0029] (2) reusing the sol-gel method to self-assemble a layer of composite shell on the surface of magnetic nanoparticles wrapped with amorphous silicon to obtain magnetic mesoporous silicon; the composite shell is composed of surfactant and silicon dioxide;

[0030] (3) calcining the magnetic mesoporous silicon, removing the surfactant in the magnetic mesoporous silicon, and obtaining a spherical magnetic composite material with mesoporous silicon dioxide as the shell;

[0031] (4) Finally, the spherical magnetic composite material is grafted with imidazole functional groups by a post...

Embodiment 1

[0048] (1) Disperse 0.10 g of magnetic ferric iron tetroxide of about 300 nm synthesized by solvothermal method into 50 ml of 0.1 mol / L HCl solution, ultrasonicate for 10 minutes, the magnetic particles are dispersed, washed with deionized water, and dispersed to the 80ml of ethanol, 20ml of deionized water and 1.0ml of mixed solution with a mass fraction of 28% ammonia, then dropwise added 0.03g of tetraethyl orthosilicate, stirred at room temperature for 6 hours, and the obtained product was washed with ethanol and water.

[0049] (2) the product obtained in step (1) is dispersed into containing 60ml ethanol, 80ml deionized water, 1.00g mass fraction is in the mixed solution of 28% ammoniacal liquor and 0.30g cetyltrimethylammonium bromide, After mechanically stirring for 30 minutes to make the solution uniform, slowly add 0.4 g of tetraethyl orthosilicate dropwise, continue mechanically stirring for 6 hours after the dropwise addition, collect the product with a magnet, and ...

Embodiment 2

[0053] (1) Disperse 0.12 g of magnetic ferric iron tetroxide of about 500 nm synthesized by solvothermal method into 50 ml of 0.1 mol / L HCl solution, ultrasonically 10 minutes, the magnetic particles are dispersed, washed with deionized water, and dispersed to the 90ml of ethanol, 10ml of deionized water and 1.0ml of mixed solution with a mass fraction of 28% ammonia, then dropwise added 0.05g of methyl orthosilicate, stirred at room temperature for 6 hours, and the obtained product was washed with ethanol and water.

[0054] (2) The product obtained in step (1) is dispersed into containing 90ml ethanol, 60ml deionized water, 1.00g mass fraction is the ammoniacal liquor of 28%, and in the mixed solution of 0.35g octadecyltrimethylammonium bromide After mechanical stirring for 30 minutes to make the solution uniform, slowly add 0.5 g of ethyl orthosilicate dropwise, continue mechanical stirring for 6 hours after the dropwise addition, collect the product with a magnet, and wash ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Layer thickness | aaaaa | aaaaa |

| Layer thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com