Method for preparing adipic acid and C4-6-dibasic acid from cyclohexane oxidation reaction byproduct

An oxidation reaction and cyclohexane technology, applied in chemical instruments and methods, preparation of organic compounds, separation/purification of carboxylic acid compounds, etc., can solve the problem of low added value of recovered products, low recovery rate of by-products, and increased production costs and other issues, to save energy consumption, easy operation, and reduce emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

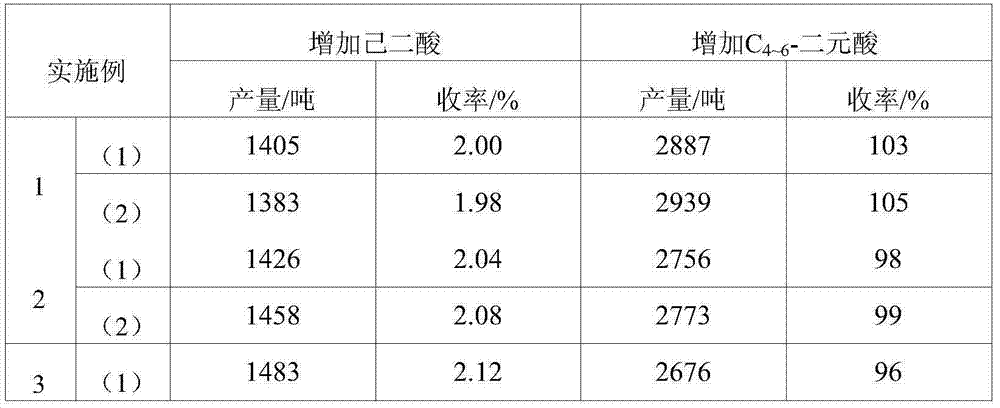

Embodiment 1

[0040] Embodiment 1 adopts the inventive method to produce adipic acid and C 4~6 -a

[0041] Get 80kg hexanaphthene air oxidation liquid from hexanaphthene air oxidation device, wash with deionized water according to oil / water ratio of 100 in extraction tower, the washing aqueous solution that obtains uses fresh hexanaphthene according to oil / water ratio 3. Carry out backwashing to obtain 1.26 kg of washing aqueous solution altogether, wherein the organic matter content is 20.6% (weight), the washing temperature is 70° C., and the operating pressure is normal pressure. The obtained washing water is evaporated and concentrated under normal pressure, and the distilled light component weight is 60%, and the concentrated solution obtained is divided into 2 parts:

[0042] (1) 1 part was oxidized with nitric acid with a content of 60%, and the reaction temperature was gradiently raised: 55±5°C, 65±5°C, 75±5°C, 85±5°C, the total reaction time was 3h, and the amount of nitric acid w...

Embodiment 2

[0044] Embodiment 2 adopts the inventive method to produce adipic acid and C 4~6 -a

[0045] Get 85kg hexanaphthene air oxidation liquid from hexanaphthene air oxidation device, wash with deionized water according to oil / water ratio of 110 in the extraction tower, the washing aqueous solution that obtains uses fresh hexanaphthene according to oil / water ratio 4. Carry out back washing to obtain 1.28kg of aqueous washing solution altogether, wherein the organic matter content is 21.8% (weight), the washing temperature is 65° C., and the operating pressure is normal pressure. The obtained washing water is subjected to atmospheric pressure evaporation and concentration, and the distilled light component weight is 58%, and the concentrated solution obtained is divided into 2 parts:

[0046](1) 1 part was oxidized with nitric acid with a content of 60%, the reaction temperature was raised by gradient: 60±5°C, 70±5°C, 80±5°C, 90±5°C, the total reaction time was 4h, and the amount of...

Embodiment 3

[0048] Embodiment 3 adopts the inventive method to produce adipic acid and C 4~6 -a

[0049] Get 75kg hexanaphthene air oxidation liquid from hexanaphthene air oxidation device, wash with deionized water according to the oil / water ratio of 95 in the extraction tower, the washing aqueous solution that obtains uses fresh hexanaphthene according to oil / water ratio 4. Perform backwashing to obtain a total of 1.209 kg of aqueous washing solution, wherein the organic matter content is 18.5 wt%, the washing temperature is 65° C., and the operating pressure is normal pressure. The obtained washing water is subjected to atmospheric pressure evaporation and concentration, and the distilled light component weight is 62%, and the concentrated solution obtained is divided into 2 parts:

[0050] (1) 1 part was oxidized with nitric acid with a content of 65%, and the reaction temperature was raised by gradient: 60±5°C, 70±5°C, 80±5°C, 90±5°C, the total reaction time was 4h, and the amount o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com