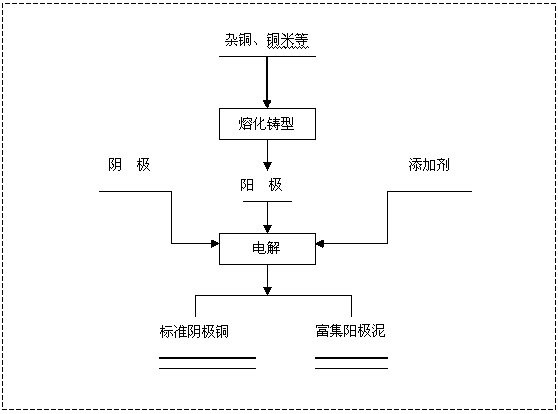

Method of directly melting and molding scrap copper to extract copper by electrolysis

A technology of electrolytic extraction and waste miscellaneous copper, which is applied to the improvement of process efficiency, photography technology, instruments, etc., can solve the problems of shortening the production process, low metal recovery rate, and high environmental protection pressure, so as to improve the comprehensive recovery capacity and shorten the production process. Technological process, the effect of improving the level of environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment one: raw material is 92% miscellaneous copper

[0028] 1. Melt the miscellaneous copper and cast it into a rectangular hole, and use the copper conductive rod as the anode, and the thin copper sheet as the cathode;

[0029] cast anode components

[0030]

[0031] 2. Prepare the electrolyte solution with copper sulfate, sulfuric acid and hydrochloric acid and add it to the electrolytic cell. The electrolyte composition: the concentration of copper sulfate is 53 g / L, the concentration of sulfuric acid is 170 g / L, and the concentration of hydrochloric acid is 0.06 g / L, so as to keep the composition of the electrolyte stable;

[0032] 3. The temperature of the electrolyte is controlled at 62°C;

[0033] 4. The cathode current density is 200A / m3, and the concentration range of copper ions, chloride ions and sulfuric acid in the electrolyte is maintained during the production process;

[0034] 5. Add 300 g / ton of bone glue to precipitate copper, and 30 g / ton o...

Embodiment 2

[0038] Embodiment two: raw material is the miscellaneous copper copper rice that contains copper 94%.

[0039] 1. The mixed copper copper rice is melted and cast into an anode plate as the anode, and a thin copper sheet as the cathode.

[0040] The cast anode composition is:

[0041]

[0042] 2. Prepare the electrolyte composition: copper ion 50 g / L, sulfuric acid 180 g / L, chloride ion 0.05 g / L, add hydrochloric acid to maintain the chloride ion concentration;

[0043] 3. The temperature of the electrolyte is controlled at 62°C;

[0044] 4. The cathode current density is 240A / m3, and the concentration range of copper ions, chloride ions and sulfuric acid in the electrolyte is maintained during the production process;

[0045] 5. Add additive bone glue 200 g / ton to precipitate copper, thiourea 20 g / ton to precipitate copper.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com