Umami-increasing seasoning and production process thereof

A technology for adding freshness to seasonings and manufacturing techniques, applied in the field of seasonings, can solve the problems of insufficient technical level, difficulty in carrying, and low price, and achieve the effect of strong and unique flavor, easy to carry, and wide range of uses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

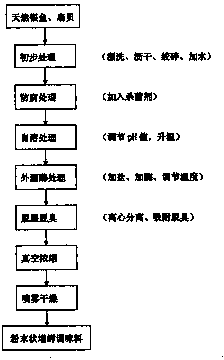

Image

Examples

Embodiment 1

[0029]Embodiment 1: The natural whitebait and scallop are sorted to remove impurities, rinse and drain, take 50 kg of natural whitebait and 50 kg of scallop, add 100 kg of water, and beat with a beater. Add 0.05% fungicide to the weight of the slurry to keep fresh and preserve; then, autodissolve the fish slurry at pH 7.0 and temperature 0-4°C for 36 hours. Then, under the conditions of pH 7.0, temperature 50°C, and sodium chloride concentration 0.5%, add 0.1 kg of papain (enzyme activity 1×104u / g), 0.1 kg of compound enzyme (enzyme activity 1.2×104u / g), 0.2 kg of flavor enzyme (enzyme activity 1.2×104u / g) was enzymatically hydrolyzed for 8 hours; then at 55°C for 8 hours; finally at 60°C for 8 hours. After the above hydrolyzate was centrifuged at a high speed by a centrifuge, 0.5% β-cyclodextrin was added to boil for 6 minutes, and then 0.05% (W / V) activated carbon was added to stir and adsorb. Afterwards, filter under a filter pressure of 0.6Mpa. Then place it in a vacuum ...

Embodiment 2

[0030] Embodiment 2: Separate the natural whitebait and scallop to remove impurities, rinse and drain, take 50 kg of natural whitebait and 50 kg of scallop, add 100 kg of water, and beat with a beater. Add 0.05% fungicide by weight of the above slurry to preserve freshness and preserve; autodissolve the fish slurry at pH 7.0 and temperature 0-4°C for 36 hours. Under the conditions of pH 7.0, temperature 50°C, and sodium chloride concentration of 0.5%, add 0.1 kg of papain (enzyme activity 1×104u / g), 0.1 kg of compound enzyme (enzyme activity 1.2×104u / g), flavor enzyme 0.2 kg (enzyme activity 1.2×104u / g) was enzymatically hydrolyzed for 8 hours; then at 55°C for 8 hours; finally at 60°C for 8 hours. Centrifuge the above hydrolyzate at high speed with a centrifuge, add 1.6 kg of β-cyclodextrin and boil for 5 minutes, then add 0.4 kg of yeast powder and heat at 40°C for 30 minutes. Then filter under the pressure of 0.6Mpa. Then place it in a vacuum concentration device, contro...

Embodiment 3

[0031] Embodiment 3: The natural whitebait and scallop are sorted to remove impurities, rinse and drain, take 50 kg of natural whitebait and 50 kg of scallop, add 100 kg of water, and beat with a beater. Add 0.05% fungicide to the weight of the slurry to keep fresh and preserve; the fish slurry is autodissolved at room temperature for 8 hours at pH 7.0. Under the conditions of pH 7.0, temperature 50°C, and sodium chloride concentration 0.5%, add 0.1 kg of papain (enzyme activity 1×104u / g), 0.1 kg of compound enzyme (enzyme 1.2×104u / g), flavor enzyme 0.2 kg (enzyme activity 1.2×104u / g) for 8 hours; then at 55°C for 8 hours; finally at 60°C for 8 hours. Centrifuge the above hydrolyzate at high speed with a centrifuge, add 1.6 kg of β-cyclodextrin and boil for 5 minutes, then add 0.4 kg of yeast powder and heat at 40°C for 30 minutes. Then filter under the pressure of 0.6Mpa. Then place it in a vacuum concentration device, control the vacuum concentration pressure to 0.08MPa, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com