Brass alloy

A brass alloy and compound phase technology, applied in the field of metal materials, can solve the problems of low tensile strength, yield strength, impact toughness, and inability to fully meet the requirements of working conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

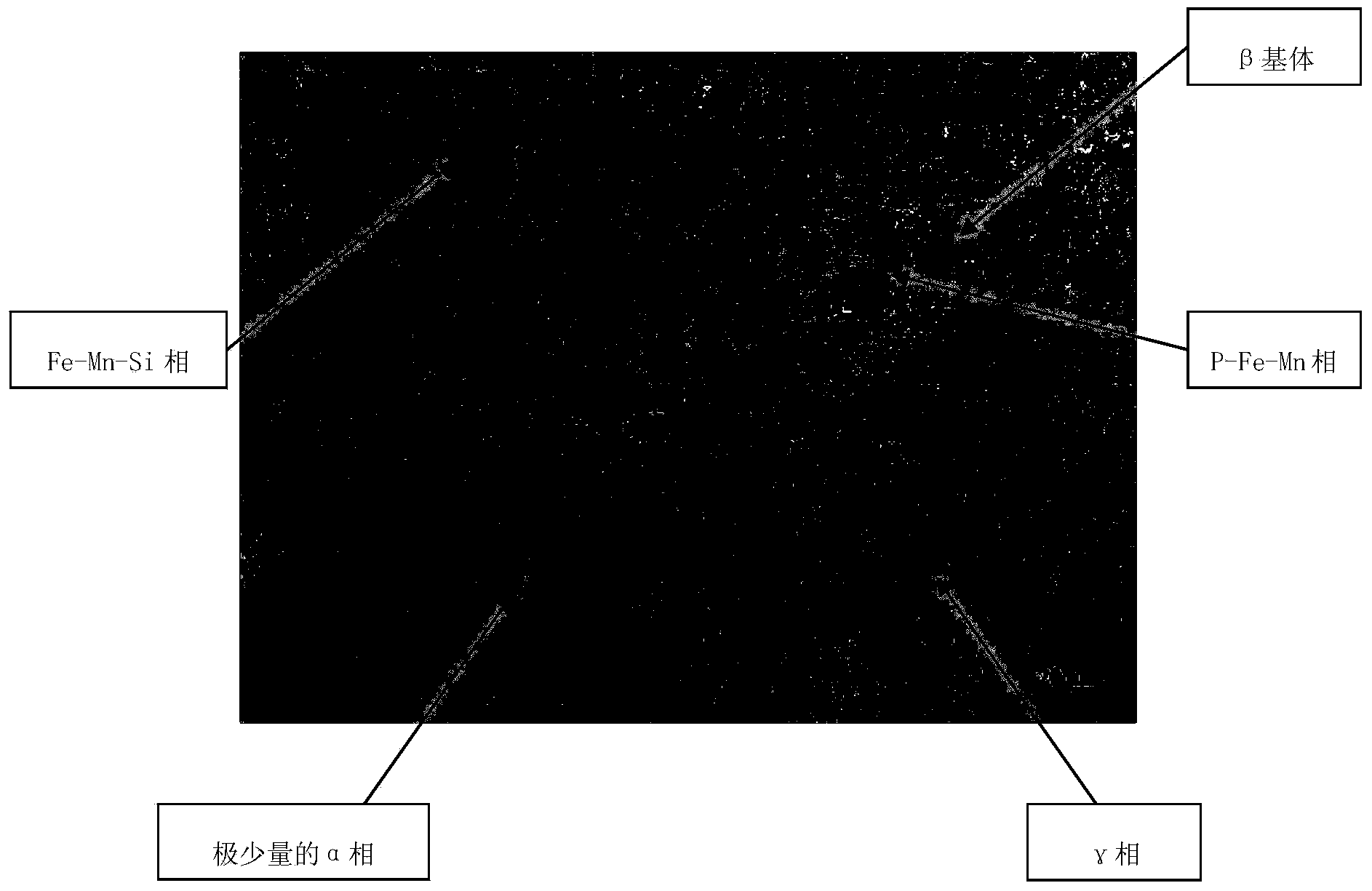

Image

Examples

preparation example Construction

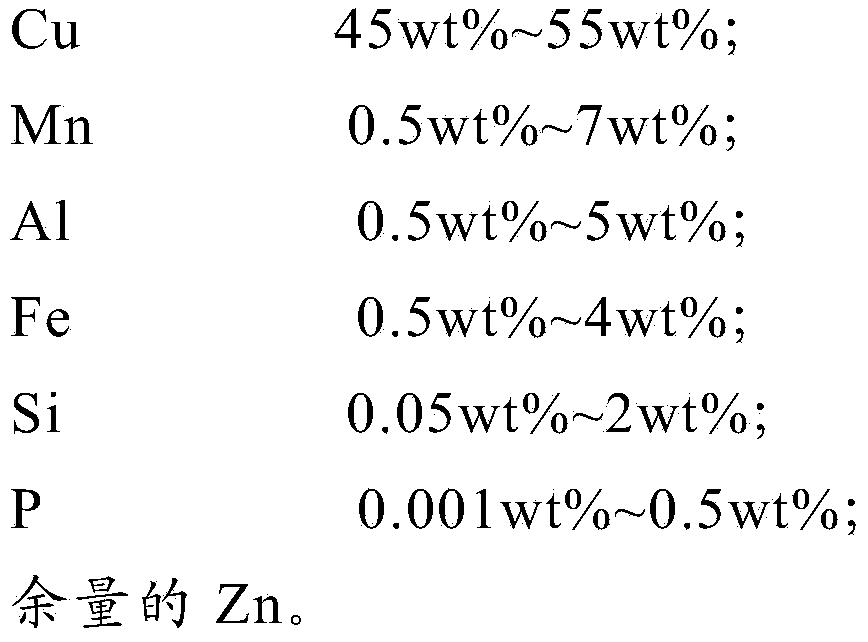

[0042] The application also provides a method for preparing a brass alloy, comprising the following steps:

[0043] preparing a brass alloy ingot, the brass alloy ingot comprising: 45wt% to 55wt% of Cu, 0.5wt% to 7wt% of Mn, 0.5wt% to 5wt% of Al, 0.5wt% to 4wt% of Fe, 0.05wt%-2wt% of Si, 0.001wt%-0.5wt% of P and the balance of Zn;

[0044] The brass alloy ingot is extruded, and the extruded brass alloy billet is heat-treated to obtain the brass alloy.

[0045] In the process of preparing the brass alloy, the present application first prepared a brass alloy ingot, in which copper, manganese, aluminum, iron, silicon, phosphorus and zinc were added; in the brass alloy Lead, nickel, chromium, tin, rare earth elements, cobalt, boron, magnesium, antimony and bismuth are also added, and the raw materials of the above metal elements are industrial pure metals or industrial pure nonmetals. The preparation process of the brass alloy ingot can be carried out in the following manner:

...

Embodiment 1

[0052] Add copper, iron, and silicon into the low-frequency smelting furnace to melt, then add manganese, aluminum, bismuth, antimony, and zinc, and finally add boron and phosphorus, and smelt at 950°C. Carry out casting afterward, obtain brass alloy ingot, the content of copper in the brass alloy ingot is 54.96wt%, the content of iron is 1.2624wt%, the content of silicon is 0.0709wt%, the content of manganese is 6.489wt%, the content of aluminum The content of bismuth is 0.9338wt%, the content of bismuth is 0.4768wt%, the content of boron is 0.1588wt%, the content of antimony is 0.0287wt%, the content of phosphorus is 0.0025wt% and the balance of zinc;

[0053] The prepared brass alloy ingot is extruded in an extruder at a temperature of 600°C, the extruded billet is annealed at a temperature of 200°C, and finally the annealed brass alloy is Straightening, sizing, packaging, and brass alloy finished products.

[0054] The properties of the brass alloy prepared in this embodi...

Embodiment 2

[0056] Add copper block, iron block, nickel block, silicon block and cobalt block into the low-frequency melting furnace, then add manganese block, aluminum block and zinc block after melting, and finally add phosphorus block, melt at 1250 °C, and cast after melting , obtain brass alloy ingot, the content of copper in the brass alloy ingot is 48.63wt%, the content of iron is 0.5321wt%, the content of silicon is 0.0557wt%, the content of manganese is 5.852wt%, the content of aluminum is 0.3402wt%, the content of nickel is 1.085wt%, the content of cobalt is 0.9587wt%, the content of phosphorus is 0.0112wt% and the balance of zinc;

[0057] The prepared brass alloy ingot is extruded in an extruder at a temperature of 750°C, the extruded billet is annealed at a temperature of 450°C, and finally the annealed brass alloy is Straightening, sizing, packaging, and brass alloy finished products.

[0058] The properties of the brass alloy prepared in this embodiment were tested, as show...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com