A kind of preparation method of low hydrolysis chloroitaconic acid epoxy resin

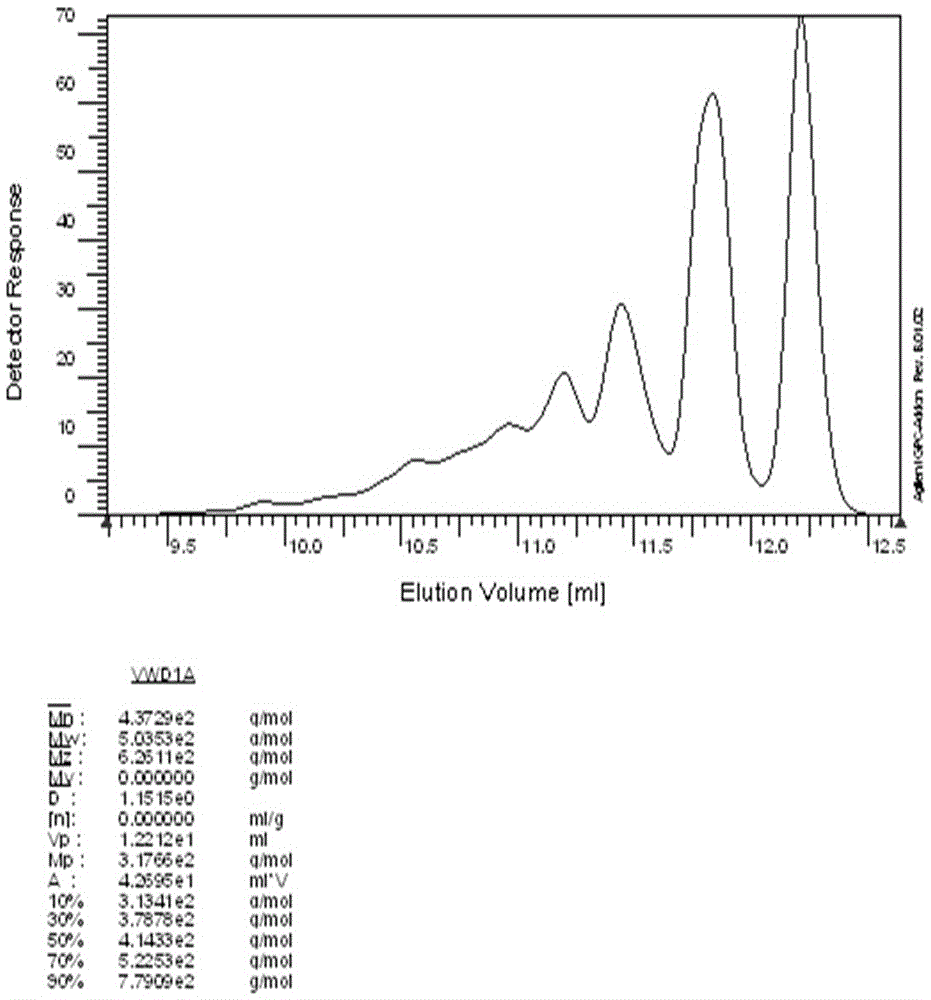

A technology of chloritaconic acid epoxy resin and itaconic acid, which is applied in the direction of organic chemistry, can solve the problems of difficult control of one-time addition of alkali, high temperature of closed-loop reaction of alkali addition, and high hydrolyzed chlorine, so as to achieve narrow molecular weight distribution and reduce Side reaction, low viscosity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

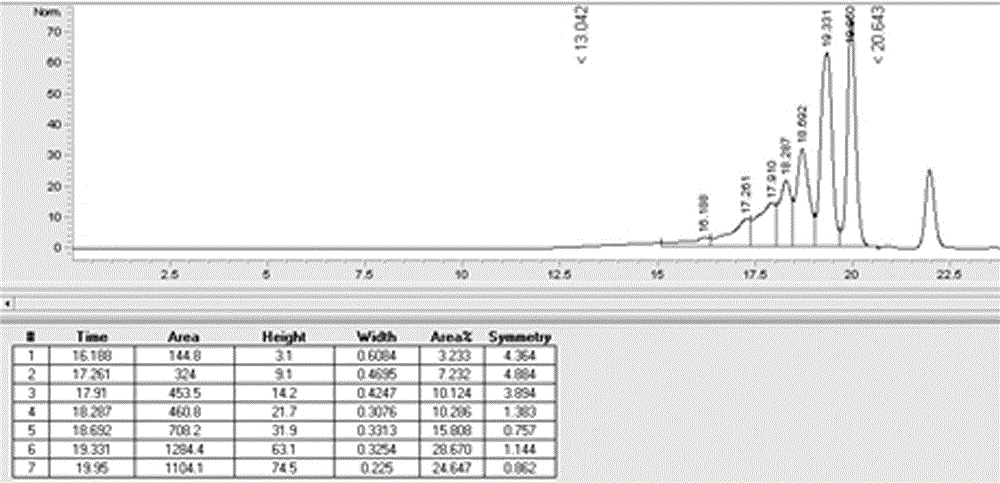

Embodiment 1

[0033] Add 100g itaconic acid (Qingdao Langyatai product, content ≥99.6%), 1986g epichlorohydrin (Shandong Haili product, content ≥99.8%), and 0.05g tetraethylammonium chloride into a 2L reaction bottle, and stir at room temperature Dissolve for 30min. Then turn on the vacuum pump, use high-purity nitrogen to break the vacuum, discharge the material and the air in the reaction bottle, and replace the air twice. Introduce high-purity nitrogen gas, raise the temperature to 90°C under normal pressure, and react at constant temperature for 2 hours. Turn on the vacuum pump, depressurize and reflux, the vacuum degree is 130Torr, cool down to 60°C, add 64.5g of 50% NaOH solution dropwise within 6h, remove the water in the system by decompression and reflux during the dropwise addition, and heat up after the dropwise addition To 88 ° C, continue to react for 3 hours, remove part of the excess epichlorohydrin. Remove the remaining epichlorohydrin by rotary evaporation, add 429g of to...

Embodiment 2

[0036] Add 100g itaconic acid (Qingdao Langyatai product, content ≥99.6%), 2065g epichlorohydrin (Shandong Haili product, content ≥99.8%), and 0.03g tetrabutylammonium bromide into a 2L reaction bottle, and stir at room temperature Dissolve for 30min. Then turn on the vacuum pump, use high-purity nitrogen to break the vacuum, discharge the material and the air in the reaction bottle, and replace the air twice. Introduce high-purity nitrogen, raise the temperature to 80°C under normal pressure, and react at constant temperature for 5 hours. Turn on the vacuum pump, depressurize and reflux, the vacuum degree is 115Torr, cool down to 55°C, add 68.9g of 50% KOH solution dropwise within 4h, remove the water in the system by decompression and reflux during the dropwise addition, and raise the temperature after the dropwise addition is completed At 90°C, continue the reaction for 3 hours to remove part of the excess epichlorohydrin. Remove the remaining epichlorohydrin by rotary ev...

Embodiment 3

[0038]Add 100g itaconic acid (Qingdao Langyatai product, content ≥99.6%), 2120g epichlorohydrin (Shandong Haili product, content ≥99.8%), 0.04g benzyltrimethylammonium chloride into a 2L reaction bottle, Stir at room temperature to dissolve for 30 minutes. Then turn on the vacuum pump, use high-purity nitrogen to break the vacuum, discharge the material and the air in the reaction bottle, and replace the air twice. Introduce high-purity nitrogen, raise the temperature to 85°C under normal pressure, and react at constant temperature for 4 hours. Turn on the vacuum pump, depressurize and reflux, the vacuum degree is 110Torr, cool down to 53°C, add 72.3g of 50% KOH solution dropwise within 3h, remove the water in the system by decompression and reflux during the dropwise addition, and raise the temperature after the dropwise addition is completed At 80°C, continue the reaction for 3 hours to remove part of the excess epichlorohydrin. The remaining epichlorohydrin was removed by...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com