Preparation method of high-strength biomass carbonaceous fuel

A biomass charcoal, high-strength technology, applied in the chemical industry, can solve the problems of poor strength and density, difficult to control quality, uneven heat, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

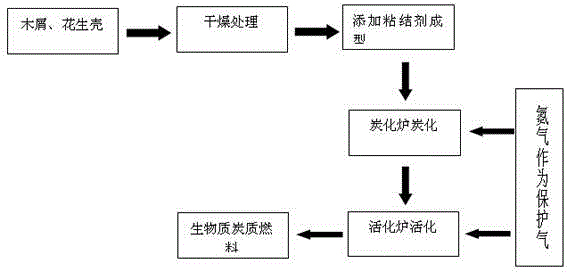

Embodiment 1

[0024] First, the sawdust and peanut shells are crushed by a crusher, and the raw materials with a particle size of no more than 1 mm are selected with a sieve, placed in a drying oven, and dried at a temperature of 105 ° C for 2 to 3 hours to control the moisture content of the materials. 7—10%, calculated according to 100g of starch, take 200ml of water, keep warm to 60°C, add 100g of starch, add 2ml of concentrated H 2 SO 4 , 2gKMnO 4 Oxidize for 1 hour, add 100g of water, 1g of quicklime and 0.4g of magnesium oxide (or iron oxide) after fully oxidizing for 1 hour, then add a solution prepared by 8g of NaOH, add 30g of borax after 20 minutes of gelatinization, and finally add water so that the mass fraction of the starch binder reaches The required percentage is 13%. Mix 70% of the above raw materials (choose peanut shells: sawdust = 1:1) with 30% starch binder (starch mass fraction 5.6%), then press and mold on the molding machine and then dry it. Treat the shaped biomas...

Embodiment 2

[0027] First, the sawdust and peanut shells are crushed by a crusher, and the raw materials with a particle size of no more than 1 mm are selected with a sieve, placed in a drying oven, and dried at a temperature of 105 ° C for 2 to 3 hours to control the moisture content of the materials. 7—10%, calculated according to 100g of starch, take 200ml of water, keep warm to 60°C, add 100g of starch, add 2ml of concentrated H 2 SO 4 , 2gKMnO 4 Oxidize for 1 hour, add 100g of water, 1g of quicklime and 0.4g of magnesium oxide (or iron oxide) after fully oxidizing for 1 hour, then add a solution prepared by 8g of NaOH, add 30g of borax after 20 minutes of gelatinization, and finally add water so that the mass fraction of the starch binder reaches The required percentage is 14%. Mix 72.5% of the above raw materials (choose peanut shells: sawdust = 1:1) with 27.5% starch binder (starch mass fraction 5.0%) and then press and mold on the molding machine and then dry it. Treat the shaped...

Embodiment 3

[0030] First, the sawdust and peanut shells are crushed by a crusher, and the raw materials with a particle size of no more than 1 mm are selected with a sieve, placed in a drying oven, and dried at a temperature of 105 ° C for 2 to 3 hours to control the moisture content of the materials. 7—10%, calculated according to 100g of starch, take 200ml of water, keep warm to 60°C, add 100g of starch, add 2ml of concentrated H 2 SO 4 , 2gKMnO 4Oxidize for 1 hour, add 100g of water, 1g of quicklime and 0.4g of magnesium oxide (or iron oxide) after fully oxidizing for 1 hour, then add a solution prepared by 8g of NaOH, add 30g of borax after 20 minutes of gelatinization, and finally add water so that the mass fraction of the starch binder reaches The required percentage is 14%. Mix 75% of the above raw materials (choose peanut shells: sawdust = 1:1) with 25% starch binder (starch mass fraction 4.4%), then press and mold on the molding machine and then dry it. Treat the shaped biomass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com