Denitration and demercuration composite catalyst and preparation method thereof

A technology of composite catalyst and co-catalyst, which is applied in the direction of catalyst carrier, chemical instrument and method, organic compound/hydride/coordination complex catalyst, etc. High cost and other issues, to achieve good adsorption and dispersion, improve activity and catalytic efficiency, and strong resistance to SO2 poisoning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

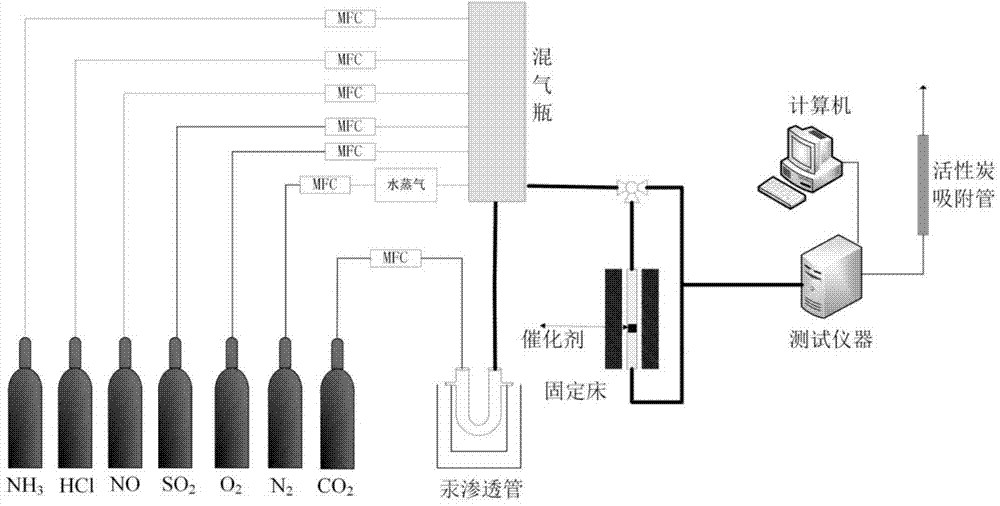

Method used

Image

Examples

Embodiment 1

[0022] Weigh 20g of chitosan, add it into 100ml, 1mol / L acetic acid solution, and stir with a magnetic stirrer for 12 hours, so that the chitosan is completely dissolved into a yellow viscous suspension. 0.588g MnO 2 and 8.823g TiO 2 into the solution, and use 10mol / L NaOH to adjust the pH value of the mixed solution to 10. The mixed solution was thoroughly stirred on a magnetic stirrer for 30 minutes, and dispersed using ultrasonic waves for 1 hour. The mixed solution was transferred into an autoclave built with polytetrafluoroethylene, and hydrothermally reacted at 160° C. for 24 hours. After the reaction, the product was centrifugally washed 5 times with distilled water and 2 times with absolute ethanol, and vacuum-dried at 60° C. for 12 hours to constant weight to obtain the catalyst. Its composition is 30% TiO 2 , 68% chitosan and 2% MnO 2 . The characteristics of the catalyst are: the specific surface area is 95m 2 / g, pore volume 0.28cm 3 / g, pore size 10.62nm. ...

Embodiment 2

[0024] Weigh 20g of chitosan, add it into 200ml, 2mol / L acetic acid solution, and stir with a magnetic stirrer for 10 hours, so that the chitosan is completely dissolved into a yellow viscous suspension. 1.052g CuO and CeO 2 Mixture, 14.035g TiO 2 Add it into the solution, and use 15mol / L NaOH to adjust the pH value of the mixed solution to 12. The mixed solution was thoroughly stirred on a magnetic stirrer for 60 minutes, and dispersed using ultrasonic waves for 2 hours. The mixed solution was transferred into an autoclave built with polytetrafluoroethylene, and subjected to hydrothermal reaction at 140° C. for 20 hours. After the reaction, the product was centrifugally washed 5 times with distilled water and 2 times with absolute ethanol, and vacuum-dried at 50° C. for 10 hours to constant weight to obtain the catalyst. Its composition is 40% TiO 2 , 57% chitosan and 3% CuO and CeO 2 . The characteristics of the catalyst are: the specific surface area is 101m 2 / g, po...

Embodiment 3

[0026] Weigh 20g of chitosan, add it into 100ml, 2mol / L acetic acid solution, and stir with a magnetic stirrer for 11 hours, so that the chitosan is completely dissolved into a yellow viscous suspension. 0.968g MnO 2 and CeO 2 Mixture, 11.291g TiO 2 Add into the solution, and use 10mol / L NaOH to adjust the pH value of the mixed solution to 9. The mixed solution was thoroughly stirred on a magnetic stirrer for 45 minutes, and dispersed using ultrasonic waves for 2 hours. The mixed solution was transferred into an autoclave built with polytetrafluoroethylene, and hydrothermally reacted at 130° C. for 22 hours. After the reaction, the product was centrifugally washed 5 times with distilled water and 2 times with absolute ethanol, and vacuum-dried at 40° C. for 11 hours to constant weight to obtain the catalyst. Its composition is 35% TiO 2 , 62% chitosan and 3% MnO 2 and CeO 2 . The characteristics of the catalyst are: the specific surface area is 120m 2 / g, pore volume ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com