A sampling device for online collection of near-infrared spectra of pulverized coal

A technology for pulverized coal and sample preparation, which is applied in sampling devices, measuring devices, material analysis by optical means, etc., to achieve the effects of convenient maintenance, high spectral repeatability, and improved adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

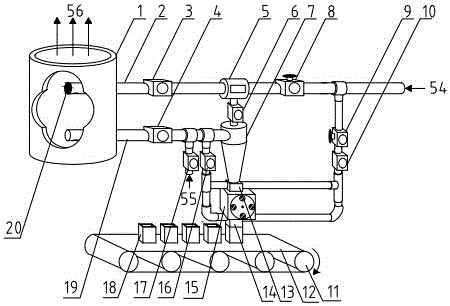

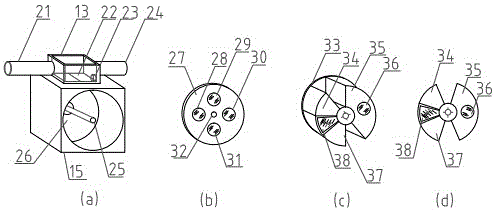

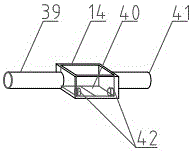

[0020] according to Figure 1~5 The specific structure and working process of the present invention will be described in detail.

[0021] The sampling and sample preparation device includes a sample processing unit, a system control unit and an outer casing.

[0022] The sample processing unit installed inside the shell box for retrieving from the pulverized coal pipeline 1 into the furnace and making a pulverized coal sample scanned by the near-infrared spectrometer 45 includes an exhaust pipe 2, a sampling pipe 19, a first electric valve 3, a second Second electric valve 6, third electric valve 4, fourth electric valve 17, fifth electric valve 16, sixth electric valve 10, negative pressure device 5, cyclone separator 7, first electric pressure regulator 8, second electric valve Pressure regulator 9, stepping track roller 11, stepping track 12, first pulverized coal temporary storage bin 13, second pulverized coal temporary storage bin 14, pulverized coal sampler 15, sample ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com