Grapheme-based composite film using bacterium as template and preparation method and application thereof

A composite film, graphene-based technology, applied in the field of nanomaterials and electrochemistry, can solve the problems of low power density, poor mechanical properties of asymmetric electrochemical capacitors, poor mechanical properties, etc., to increase the contact area, excellent Cycle stability, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

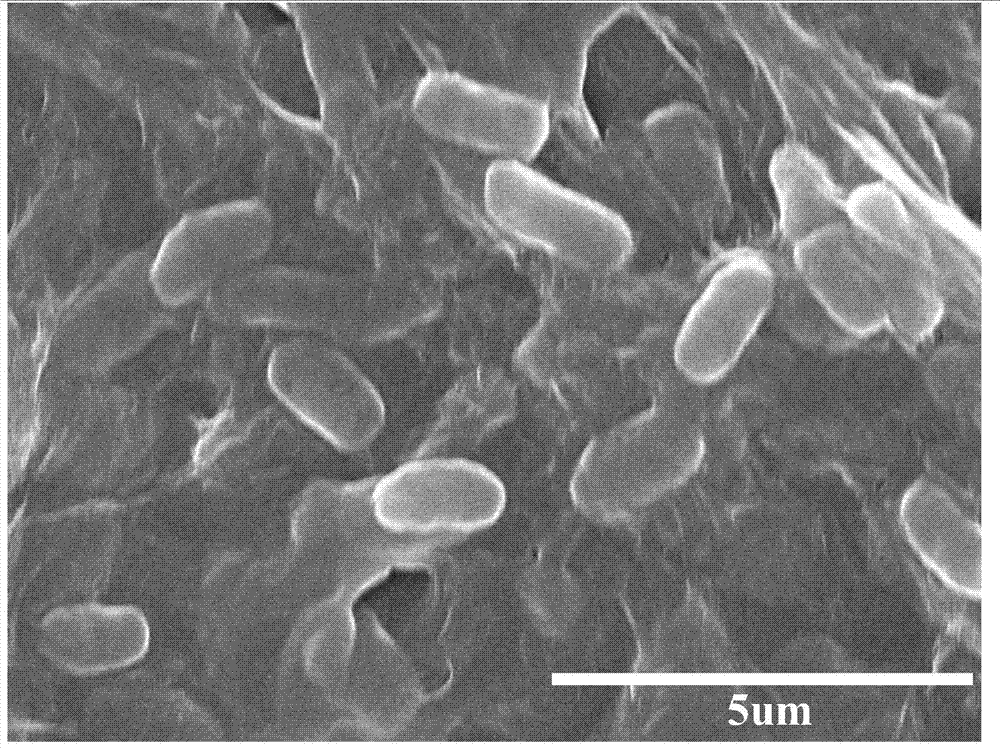

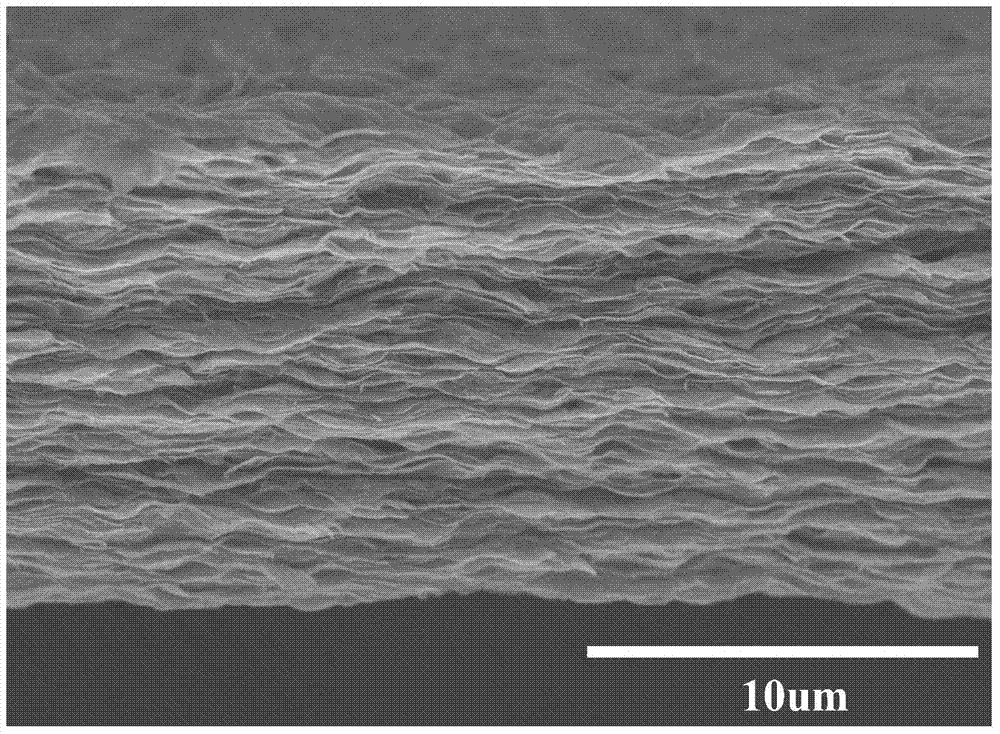

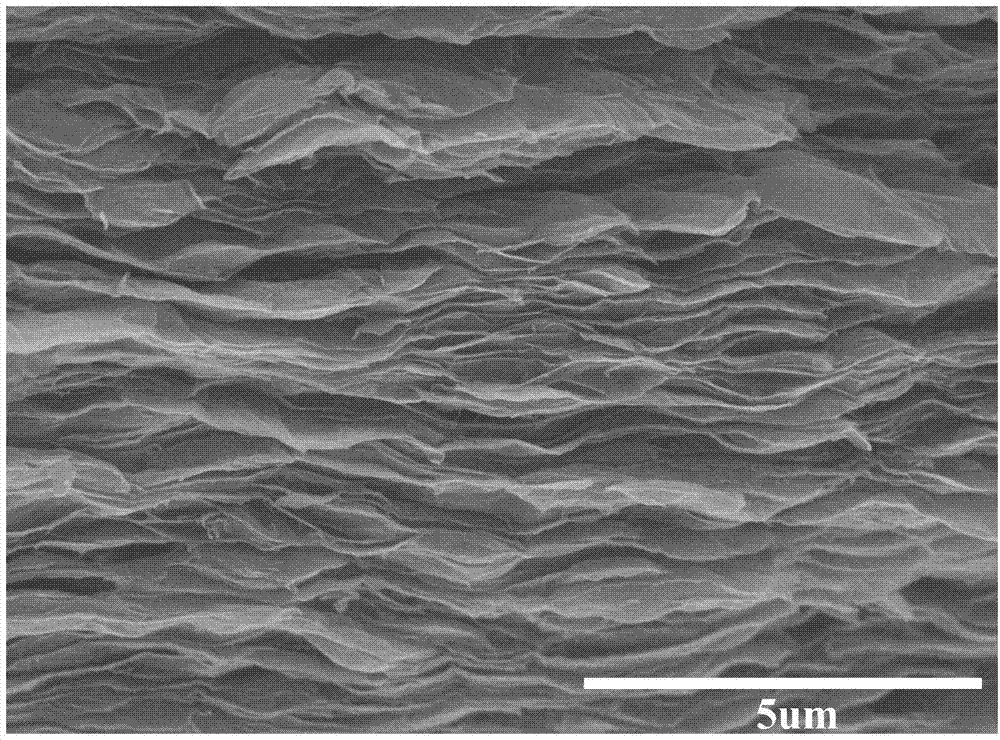

[0052] Take 30mL of Bacillus subtilis aqueous solution (OD 600nm 2.0) with 20mL MnSO 4 (50mM) and Na 2 SO 4 (50mM) mixed solution was stirred and reacted at room temperature for 10h, then centrifuged and washed with deionized water; the product was dispersed in 10mL graphene oxide solution (2.0mg / mL), oscillated evenly, and the homogeneous mixed solution was vacuum filtered , the filter cake was peeled off from the filter membrane, dried naturally, and then annealed at 500°C for 5h under argon atmosphere to obtain graphene / MnO x Composite film.

[0053] The resulting composite film was cut into The wafers can be directly used as supercapacitor electrode materials without any binder and conductive agent. Select two pieces of similar quality as the electrode material, glass fiber membrane as the diaphragm, 1M NaSO 4 Using aqueous solution as the electrolyte, a two-electrode supercapacitor was assembled with a Swagelok cell, and its electrochemical performance was tested o...

Embodiment 2

[0059] Take 30mL of Bacillus subtilis aqueous solution (OD 600nm 2.0) with 20mL MnSO 4 (20mM) and Na 2 SO 4 (20 mM) the mixed solution was stirred and reacted for 5 h in the dark, then centrifuged, and the obtained product was washed with deionized water. Disperse the product in 10 mL of graphene oxide solution (2.0 mg / mL), vacuum filter the homogeneous mixture, peel off the filter cake from the filter membrane, dry it naturally, and then anneal at 500 °C for 5 h under an argon atmosphere. Graphene / MnO x Composite film.

[0060] The resulting composite film was cut into The wafers can be directly used as supercapacitor electrode materials without any binder and conductive agent. Select two pieces of similar quality as the electrode material, glass fiber membrane as the diaphragm, 1M NaSO 4 The aqueous solution was used as the electrolyte, and a two-electrode supercapacitor was assembled with a Swagelok cell, and its electrochemical performance was tested on the two-ele...

Embodiment 3

[0062] Take 30mL of micrococcus aqueous solution (OD 600nm 2.0) with 30mL Mn(NO 3 ) 2 (50mM) and NaNO 3 (50 mM) the mixed solution was stirred and reacted for 10 h under dark conditions, then centrifuged, and the obtained product was washed with deionized water. Disperse the product in 10 mL of graphene oxide solution (2.0 mg / mL), vacuum filter the homogeneous mixture, peel off the filter cake from the filter membrane, dry it naturally, and then anneal at 500 °C for 5 h under an argon atmosphere. Graphene / MnO x Composite film.

[0063] The resulting composite film was cut into The wafers can be directly used as supercapacitor electrode materials without any binder and conductive agent. Select two pieces of similar quality as the electrode material, glass fiber membrane as the diaphragm, 1M NaSO 4 The aqueous solution was used as the electrolyte, and a two-electrode supercapacitor was assembled with a Swagelok cell, and its electrochemical performance was tested on the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com