Slow release aromatic base material, particles as well as preparation method and application thereof

A slow-release, fragrance-retaining technology, applied in applications, tobacco, e-liquid filters, etc., can solve the problems of unreachable fragrance additives, high production costs, and insufficient fragrance, so as to achieve a perfect and harmonious aroma of tobacco and alcohol. , Improve the quality of suction, strengthen the effect of characteristic style

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] 1. Experimental raw materials

[0055] Chitosan, polyethylene glycol 400, polyacrylic acid resin, calcium carbonate, sodium bicarbonate, porous starch

[0056] 2. Experimental method

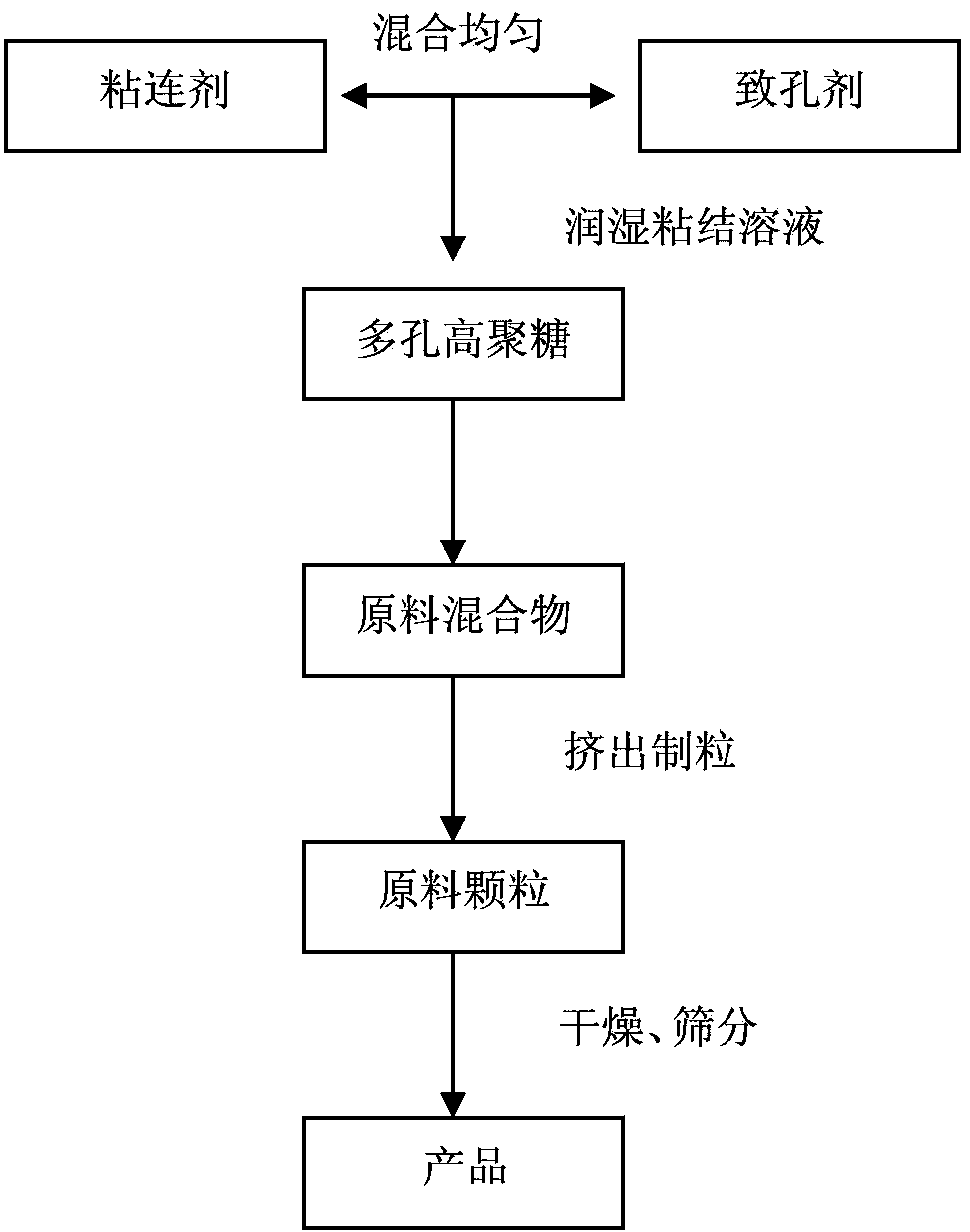

[0057] 1. Mix chitosan, polyethylene glycol 400, polyacrylic acid resin, calcium carbonate, and sodium bicarbonate in a ratio of 1:1:1:1:2 to obtain a porogen.

[0058] 2. Mix the porogen mixed in the previous step with pure water at a ratio of 5:16, and fully dissolve (the pure water used in the present invention is ionized water) to obtain a bonding mixed solution.

[0059] 3. Spray the wet bonding solution prepared in 2 evenly on the porous polysaccharide according to the ratio of 9:1, change from spray to mix evenly, and prepare the raw material mixture.

[0060] 4. The raw material mixture prepared in 3 is made into raw material granules by extrusion granulation.

[0061] 5. Put the granules made in 4 into a microwave plate according to the quantity of 800 grams per portion, put t...

Embodiment 2

[0068] 1. Experimental raw materials

[0069] Chitosan, polyethylene glycol 400, polyacrylic acid resin, calcium carbonate, sodium bicarbonate, porous polysaccharide

[0070] 2. Experimental method

[0071] 1. Mix chitosan, polyethylene glycol 400, polyacrylic acid resin, calcium carbonate, and sodium bicarbonate in a ratio of 2:3:3:8:0.

[0072] 2. Mix the porogen mixed in 1 with purified water at a ratio of 8:1, and dissolve fully to prepare a wetting and bonding solution.

[0073] 3. Spray the wetting and bonding solution prepared in 2 evenly on the porous polysaccharide according to the ratio of 1:7, change the spraying and mixing evenly, and make a raw material mixture that is lightly kneaded into a ball and disperses when lightly pressed.

[0074] 4. The raw material mixture prepared in 3 is made into raw material granules of a certain shape and size by extrusion granulation.

[0075] 5. Put the granules made in 4 into a microwave plate according to the quantity of 80...

Embodiment 3

[0082] 1. Experimental raw materials

[0083] Chitosan, polyethylene glycol 400, polyacrylic acid resin, calcium carbonate, sodium bicarbonate, porous polysaccharide

[0084] 2. Experimental method

[0085] 1. Mix chitosan, polyethylene glycol 400, polyacrylic acid resin, calcium carbonate, and sodium bicarbonate in a ratio of 1:2:1:1:3.

[0086] 2. Mix the porogen mixed in 1 with purified water at a ratio of 4:11, and dissolve fully to prepare a wetting and bonding solution.

[0087] 3. Spray the wetting and bonding solution prepared in 2 evenly on the porous polysaccharide according to the ratio of 2:7, change the spraying and mixing evenly, and make a raw material mixture that is lightly kneaded into a ball and disperses when lightly pressed.

[0088] 4. The raw material mixture prepared in 3 is made into granules of a certain shape and size by extrusion granulation.

[0089] 5. Put the granules made in 4 into a microwave plate according to the quantity of 800 grams per ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com