Laminated microneedle system and preparation method thereof

A microneedle and lamination technology, applied in the field of microneedle arrays, can solve the problems of limited hardness of soluble materials, insufficient compression resistance, unfavorable operation, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

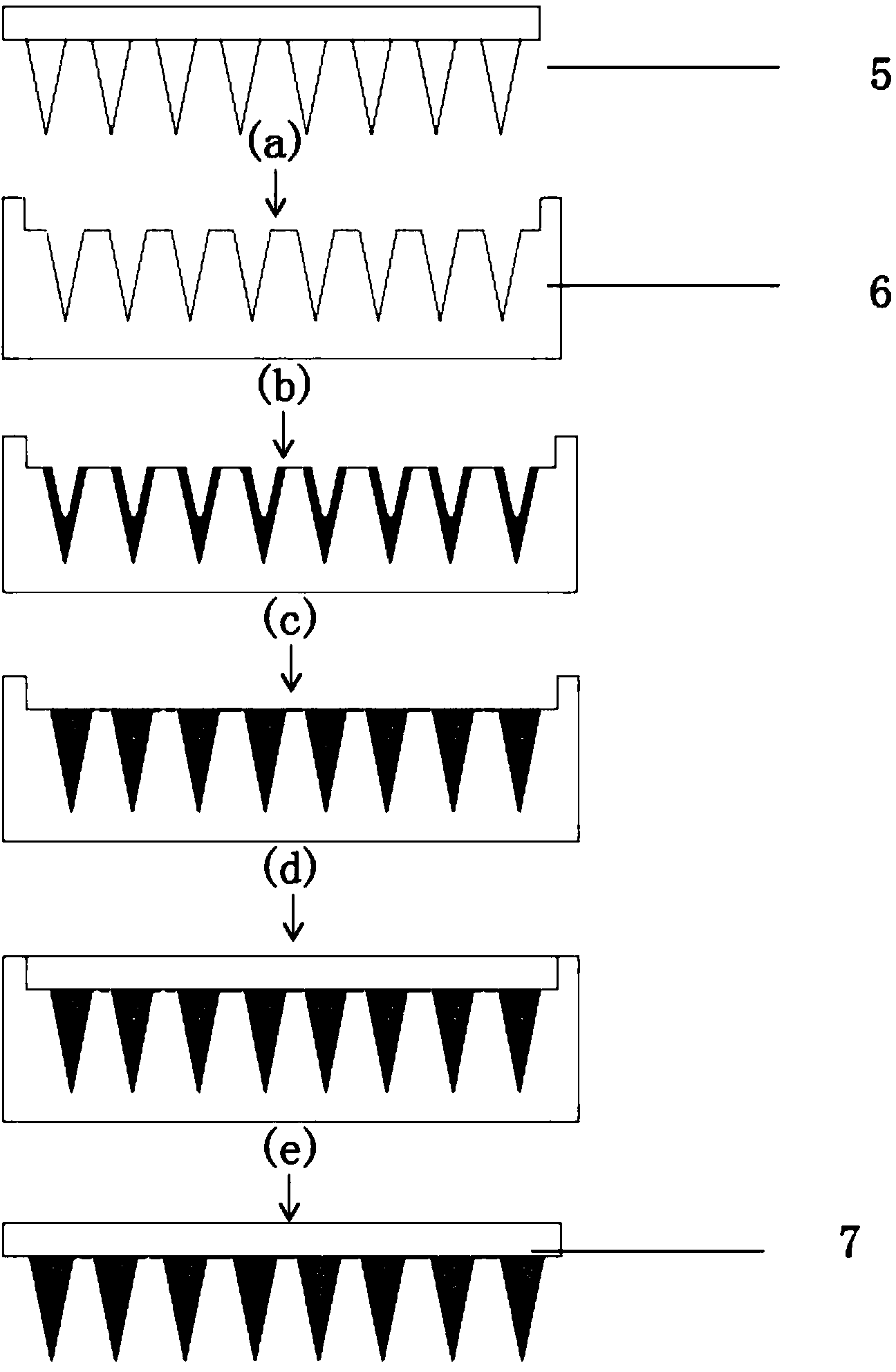

[0024] The preparation method of the laminated microneedle system provided by the invention (see image 3 ), specifically include the following steps:

[0025] (a) Making a microneedle master 5: preparing a microneedle master of silicon material or metal material by using micro-nano processing technology, laser cutting or mechanical engraving;

[0026] (b) Make microneedle template 6: Mix polydimethylsiloxane prepolymer and curing agent in a volume ratio of 8:1 to 12:1 (the curing agent is preferably a silicone rubber curing agent or other types of curing agent) agent), after fully stirring evenly and vacuuming, remove the air bubbles, then pour the liquid polydimethylsiloxane with curing agent onto the microneedle motherboard, and place it in an oven at 70-85°C for 1 to 2 hours. Obtain solid polydimethylsiloxane, and then tear it off from the microneedle master to form a microneedle template with arrayed microholes;

[0027] (c) Preparation of the outer layer of the needle ...

Embodiment 1

[0034] (a) Microneedle master plate of stainless steel material prepared by laser cutting method;

[0035] (b) Fabrication of polydimethylsiloxane microneedle templates using microneedle masters. Mix polydimethylsiloxane prepolymer and silicone rubber curing agent at a volume ratio of 8:1, stir well and vacuumize, remove air bubbles, and then add the liquid polydimethylsiloxane with curing agent Pour alkane onto the microneedle master, place it in an oven at 70°C for 2 hours, and obtain solid polydimethylsiloxane, which is then torn off from the microneedle master to form an array of microneedles. Porous polydimethylsiloxane microneedle template;

[0036] (c) Preparation of the outer layer of the needle body: After mixing the silk fibroin solution with a mass volume ratio of 7.8% and 0.2IU insulin in a volume ratio of 4:1 to form a mixed solution, the needle body array with a volume of 3 / 4 The total volume of the mixed solution was poured onto the polydimethylsiloxane micron...

Embodiment 2

[0040](a) Microneedle master plate of silicon material prepared by micro-nano processing technology;

[0041] (b) Fabrication of polydimethylsiloxane microneedle templates using microneedle masters. Mix the polydimethylsiloxane prepolymer and the silicone rubber curing agent at a volume ratio of 10:1, stir well and vacuumize, remove the air bubbles, and then add the curing agent to the liquid polydimethylsiloxane Pour alkane onto the microneedle master, place it in an oven at 80°C for 1.5 hours to obtain solid polydimethylsiloxane, and then tear it off from the microneedle master to form an array of microneedles. Porous polydimethylsiloxane microneedle template;

[0042] (c) Preparation of the outer layer of the needle body: After mixing the hyaluronic acid solution with a mass volume ratio of 15% and the hepatitis B vaccine of 20 μg / mL in a volume ratio of 10:1 to form a mixed solution, the needle with a volume of 5 / 8 The mixed solution of the total volume of the body array...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com