Perishable organic matter oxidizing agent, treatment system and method for preparing humic acid-contained fertilizers

A treatment system and organic matter technology, applied in the preparation of organic fertilizers, organic fertilizers, bio-organic part treatment, etc., can solve problems such as uneven treatment, equipment corrosion, and affecting product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

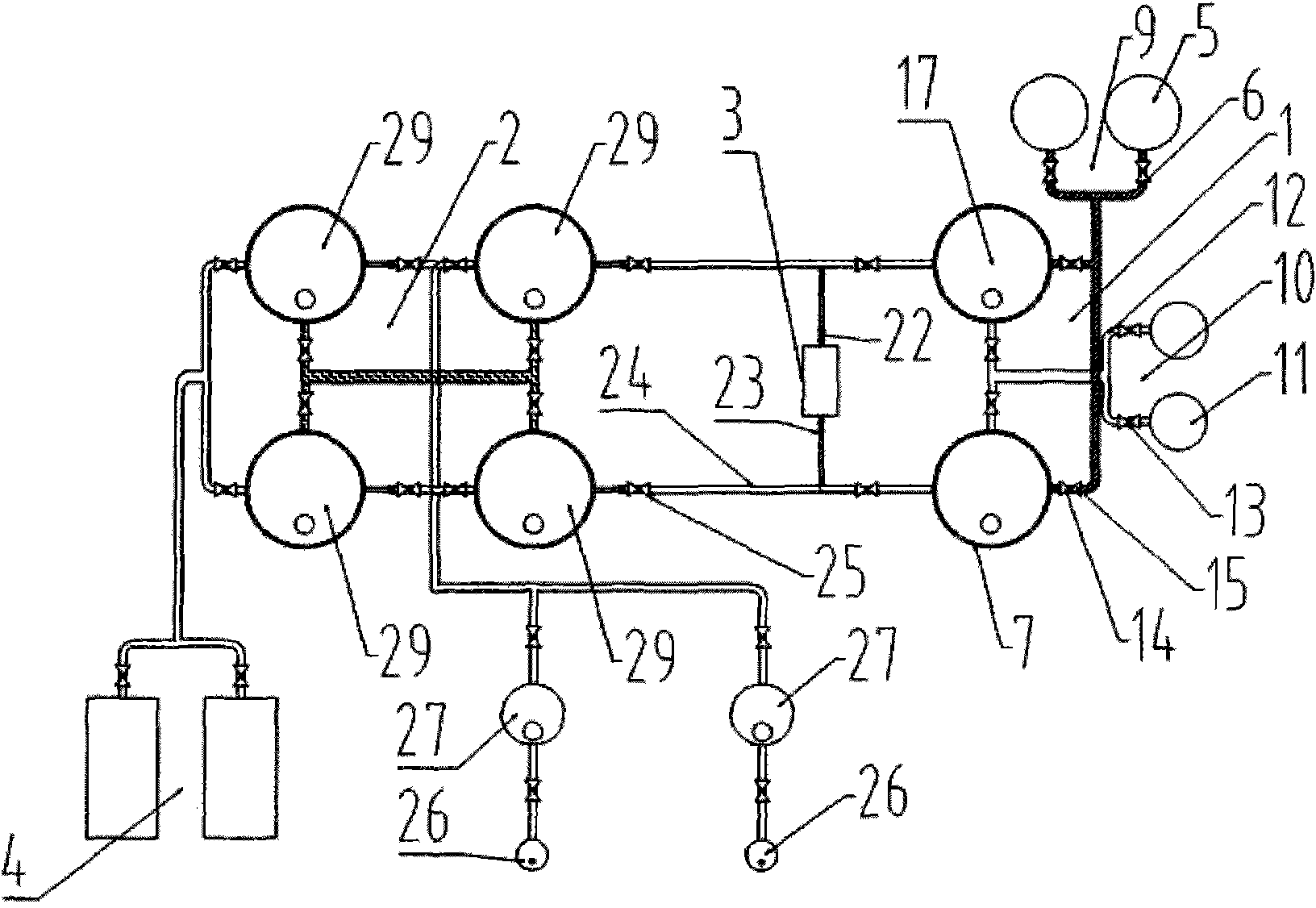

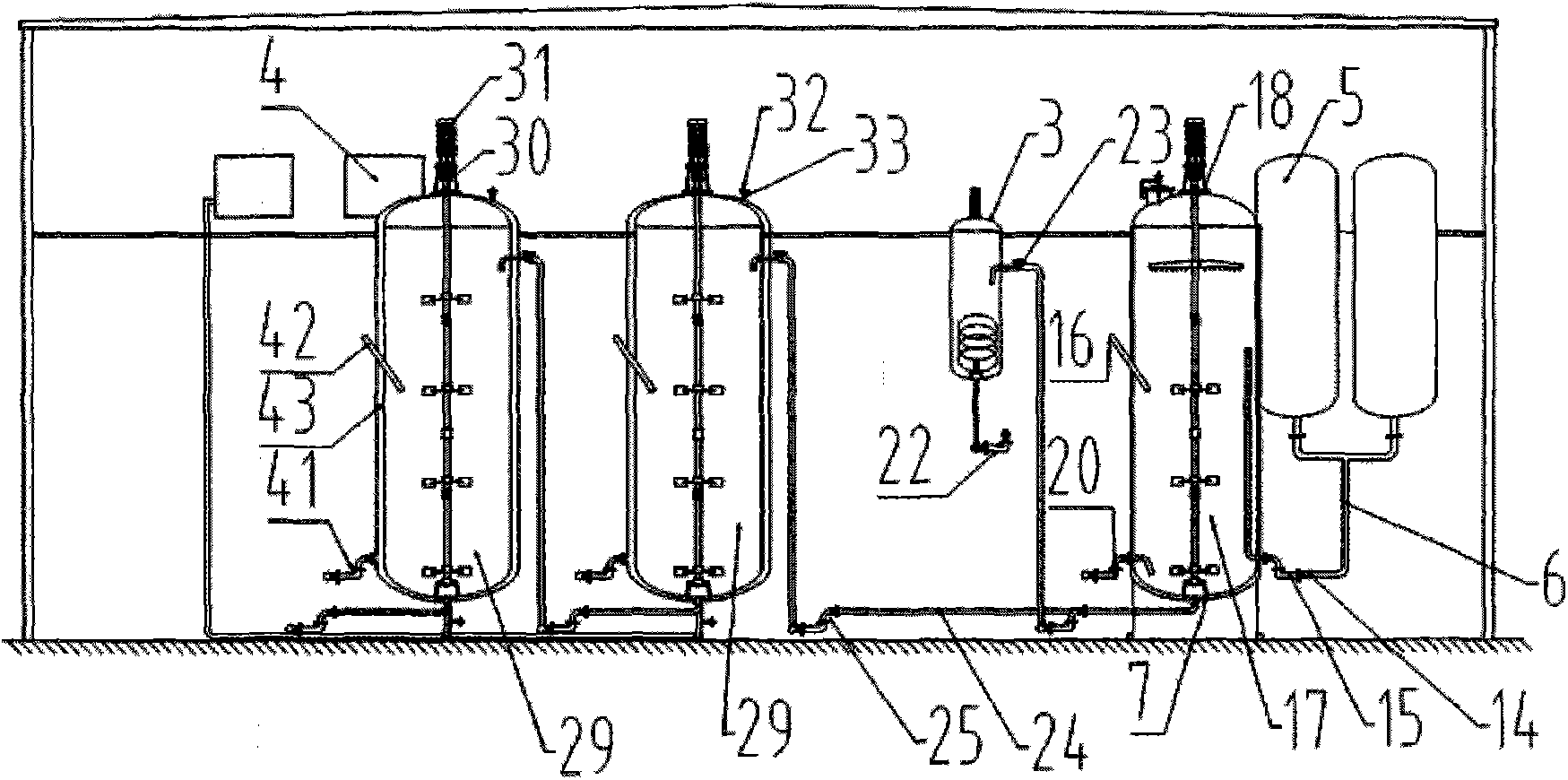

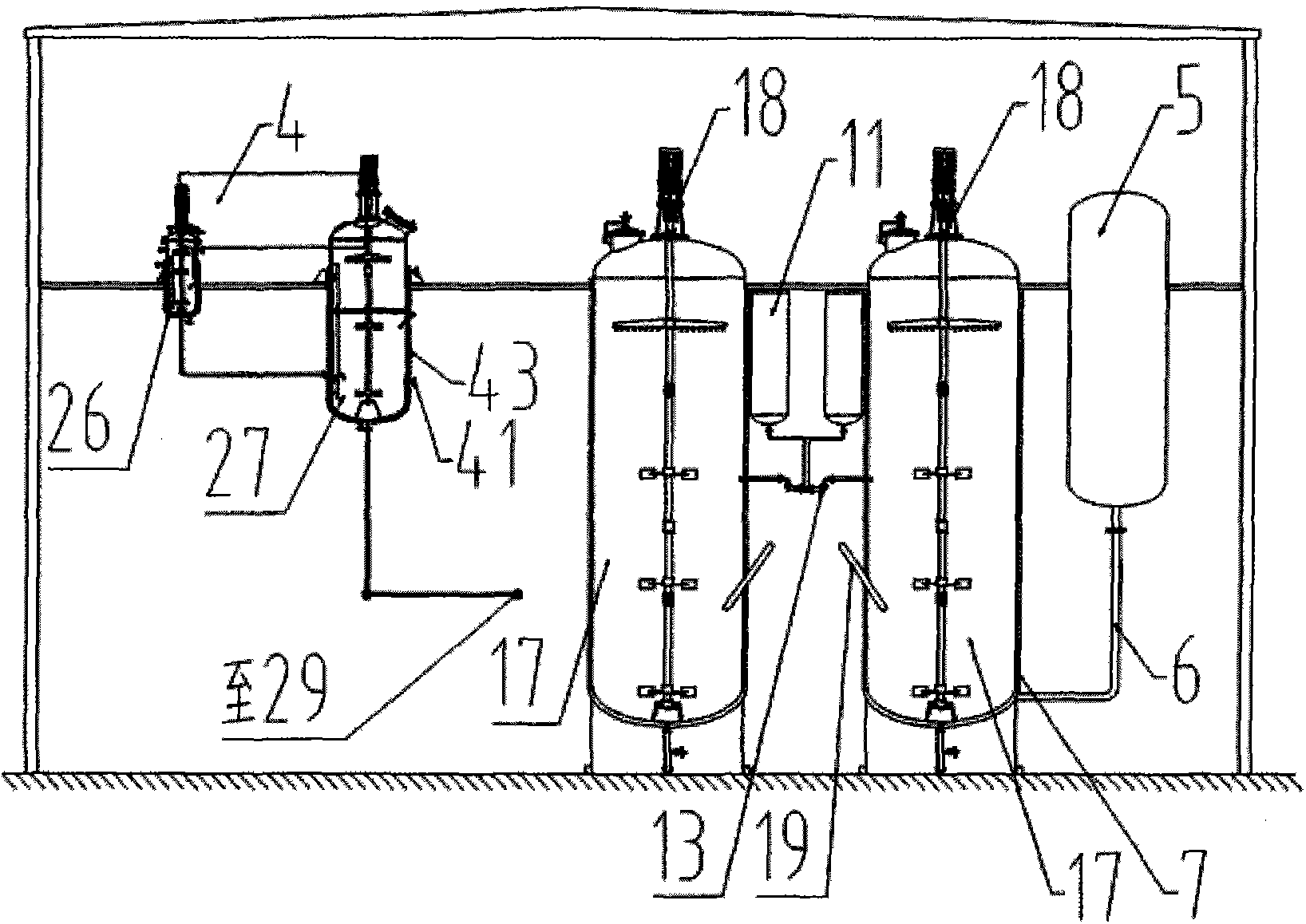

[0073] Example 1 Sewage Plant Dewatered Sludge Treatment System

[0074] Such as figure 1 , figure 2 , image 3 As shown, the closed pipeline pressure pump (25) is opened, the feed valve (23) is opened, the reaction tank (7) is connected with the mill (3), and the mill (3) is connected with another reaction tank (7) , two reaction tanks (7) form a series connection.

[0075] The present invention prepares humic acid-containing water-soluble fertilizer, comprising the following steps:

[0076] (a) The first H 2 o 2 Oxidation: The H 2 o 2 Oxidation unit 1, comprises: reaction tank device 17, the H2 that is connected with reaction tank device 17 2 o 2 Liquid device 9, the lye adding device 10 connected with the reaction tank device 17; the alkaline protective agent is added in the dewatered sludge, and the pH value is adjusted to be greater than 6.5; the dehydrated sludge, 5wt% sodium hydroxide solution, 10wt% h 2 o 2 The mass parts of the solution are 91.9:0.1:8; th...

Embodiment 2

[0087] Example 2 Sewage Plant Dewatered Sludge Treatment System

[0088] Such as figure 1 , figure 2 , image 3 As shown, the closed pipeline pressure pump (25) is opened, the feed valve (23) is opened, the reaction tank (7) is connected with the mill (3), and the mill (3) is connected with another reaction tank (7) , two reaction tanks (7) form a series connection.

[0089] The present invention prepares humic acid-containing water-soluble fertilizer, comprising the following steps:

[0090] (a) The first H 2 o 2 Oxidation: The H 2 o 2 Oxidation unit 1, comprises: reaction tank device 17, the H2 that is connected with reaction tank device 17 2 o 2 Liquid device 9, the lye adding device 10 connected with the reaction tank device 17; the alkaline protective agent is added in the dewatered sludge, and the pH value is adjusted to be greater than 6.5; the dehydrated sludge, 10wt% sodium silicate solution, 10wt% h 2 o 2 The mass parts of the solution are 91.9:0.1:8; th...

Embodiment 3

[0101] Example 3 Sewage Plant Dewatered Sludge Treatment System

[0102] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, close the feed valve (23), open the pipeline pressure pump (25), the reaction tank (7) is connected with the biological acidification tank (29), and the two reaction tanks (7) form a parallel connection.

[0103] The present invention prepares the compound fertilizer containing humic acid, comprises the following steps:

[0104] (a)H 2 o 2 Oxidation: The H 2 o 2 Oxidation unit 1, comprises: reaction tank device 17, the H2 that is connected with reaction tank device 17 2 o 2 Liquid device 9, the lye adding device 10 connected with the reaction tank device 17; the alkaline protective agent is added in the dewatered sludge, and the pH value is adjusted to be greater than 6.5; the dehydrated sludge, 5wt% sodium hydroxide solution, 20wt% h 2 o 2 The mass parts of the solution are 91.85:0.15:8; the oxidation temperature: 105°C, react for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com