Ultraviolet-proof and biodegradable packaging film

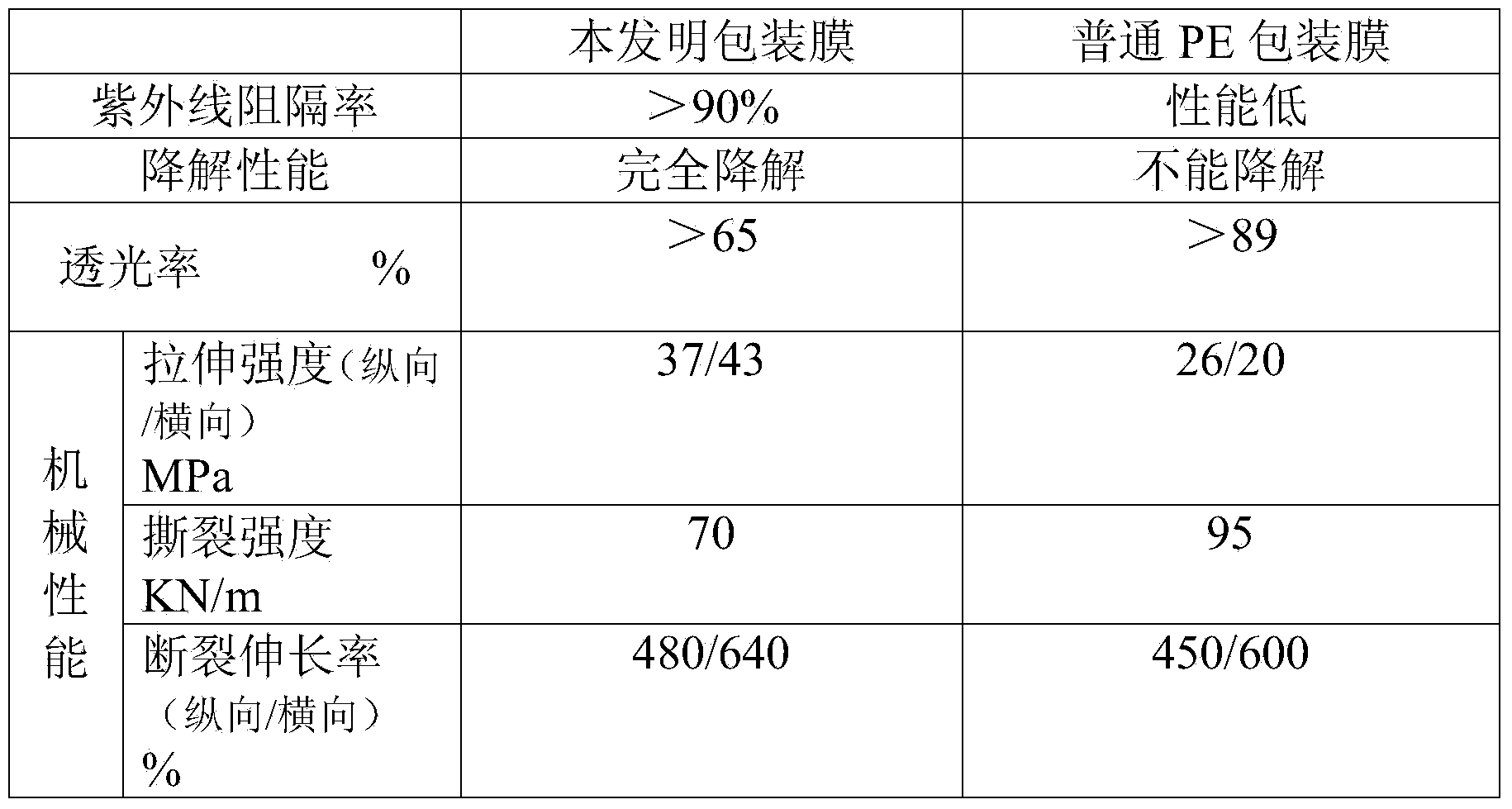

A biodegradable and ultraviolet technology, applied in the field of packaging film, can solve the problem of poor anti-ultraviolet ability, achieve good physical and mechanical properties, strong ultraviolet blocking rate, and long-term packaging protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0025] Take 2.5 parts of 2-hydroxy-4-n-octyloxybenzophenone, 3 parts of 2,4,6-tris(2'n-butoxyphenyl)-1,3,5-triazine, 1 part of 2 -(2'-Hydroxy-3',5'-di-tert-phenyl)-5-chlorinated benzotriazole and 1.5 parts of 4-benzoyloxy-2,2,6,6-tetramethylpiper Pyridine, added to a high-speed mixer for mixing and compounding, then granulated, and then dried in an electric dryer at 60°C for 8 hours to make an anti-ultraviolet compound agent for use.

[0026] Take 60 parts of poly-β-hydroxybutyric acid (product of Jiangsu Nantian Group Co., Ltd.) and 40 parts of β-hydroxyvaleric acid (Ningbo Tianan Biomaterials Co., Ltd.), add them to a high-speed mixer for mixing and compounding, and then granulate them. Use an electric dryer to dry at 60°C for 8 hours to prepare poly-β-hydroxybutyric acid and β-hydroxyvaleric acid copolymer for later use.

[0027] Take 100 parts of poly-β-hydroxybutyric acid and β-hydroxyvaleric acid copolymer, 5 parts of aluminum powder (product of Angang Industrial Fine A...

example 2

[0031] Take 2.5 parts of 2-hydroxy-4-n-octyloxybenzophenone, 3 parts of 2,4,6-tris(2'n-butoxyphenyl)-1,3,5-triazine, 1 part of 2 -(2'-Hydroxy-3',5'-di-tert-phenyl)-5-chlorinated benzotriazole and 1.5 parts of 4-benzoyloxy-2,2,6,6-tetramethylpiper Pyridine, added to a high-speed mixer for mixing and compounding, then granulated, and then dried in an electric dryer at 60°C for 8 hours to make an anti-ultraviolet compound agent for use.

[0032] Take 60 parts of poly-β-hydroxybutyric acid (product of Jiangsu Nantian Group Co., Ltd.) and 40 parts of β-hydroxyvaleric acid (Ningbo Tianan Biomaterials Co., Ltd.), add them to a high-speed mixer for mixing and compounding, and then granulate them. Use an electric dryer to dry at 60°C for 8 hours to prepare poly-β-hydroxybutyric acid and β-hydroxyvaleric acid copolymer for later use.

[0033] Take 100 parts of poly-β-hydroxybutyric acid and β-hydroxyvaleric acid copolymer, 5 parts of aluminum powder (product of Angang Industrial Fine A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com