Porphyrin optical sensing functional film suitable for detecting heavy metal ions and preparation method of porphyrin optical sensing functional film

A heavy metal ion and optical sensing technology, applied in the field of membrane materials, can solve the problems that optical indicators are difficult to recycle and affect practical applications, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Dissolve the dried polysulfone (PSF) in chloroform, then place the round-bottomed flask in an ice-water bath, add paraformaldehyde, trimethylchlorosilane, tin tetrachloride, and the molar ratio of the three It is 100:100:1. After the temperature was raised to 50° C., the reaction was stirred by magnetic force for 40 h. After the reaction stopped, most of the solvent was removed by rotary evaporation and the concentrated solution was precipitated in 10 times the volume of ethanol, and then purified by dissolution and precipitation, the product was dried in a vacuum drying oven until the quality was constant, and the chloromethylation rate was 80%. .

[0024] (2) Chloromethylated polysulfone (CMPSF, 15wt%), polyethylene glycol 400 (PEG400, 10wt%), N-N dimethylacetamide (DMAC, 75wt%) were added in the three-necked flask successively according to the proportion, and heated Stir at 60°C for 4 hours to obtain a homogeneous and transparent casting solution. After standin...

Embodiment 2

[0030] (1) According to the method of step (1) (2) in Example 1, a CMPSF film with a chloromethylation rate of 30% and a thickness of 110 μm was prepared.

[0031] (2) Immerse the CMPSF membrane obtained in step (1) in a certain volume of 20% trimethylamine aqueous solution, and magnetically stir for 10 h in a water bath at 30° C. to obtain a quaternized polysulfone (QAPSF) membrane. Wash the QAPSF membrane with pure water until it is neutral.

[0032] (3) Immerse the QAPSF membrane in a certain concentration and volume of TPPS solution, realize the loading of TPPS by electrostatic action, and then get the QAPSF / TPPS membrane after washing with pure water, the loading of TPPS on the membrane is relative to the weight of the QAPSF membrane 3mg / g.

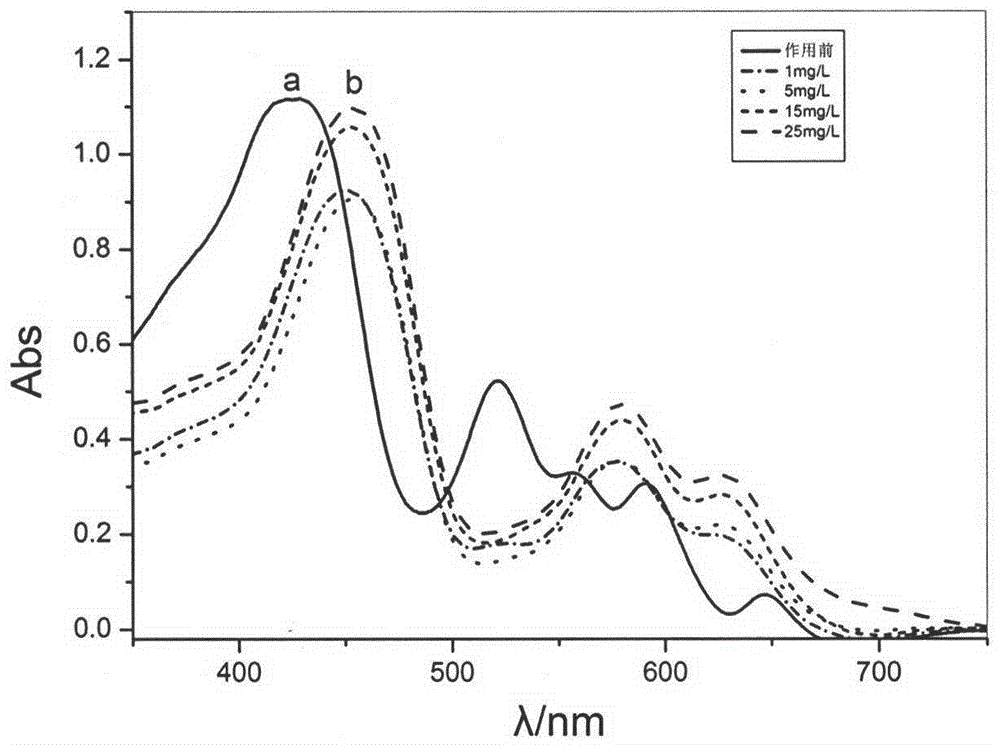

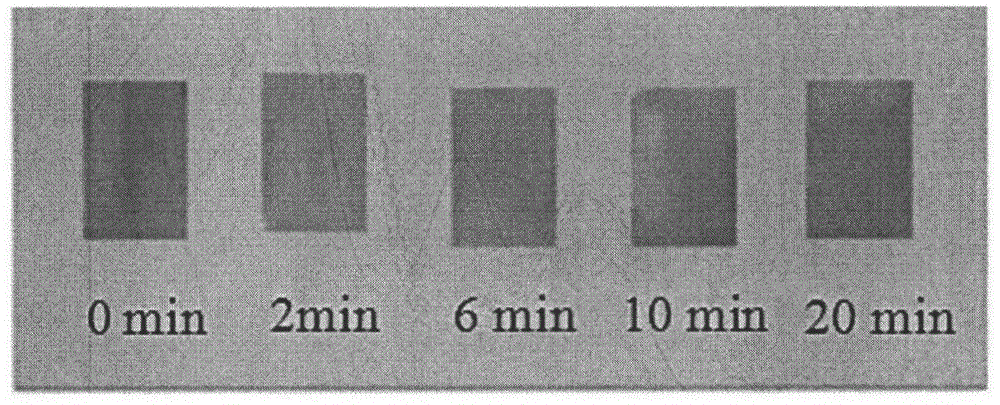

[0033] (4) The obtained film was characterized by an ultraviolet spectrophotometer, and its absorption wavelength in the ultraviolet absorption spectrum was 422 nm. When the membrane was placed in Tris / HCl buffer solution of pH=9.0...

Embodiment 3

[0036] (1) Add PVA (10wt%) and deionized water (90wt%) into a three-necked flask, heat and stir at 100°C until the PVA is completely dissolved, add oxalic acid (0.01-10wt%) and sulfuric acid (0.01-1wt%) to the PVA In the solution, continue heating and stirring for 3 hours to obtain an oxalic acid cross-linked casting solution, cast the casting solution on a smooth and clean glass plate, and evaporate to form a film at room temperature. The film thickness was 50 μm.

[0037] (3) Immerse the PVA film in a TAPP aqueous solution of a certain concentration and volume, oscillate and adsorb to realize the load of TAPP, and then get the PVA / TAPP film after washing with pure water, and the TAPP load is 8 mg / g relative to the weight of PVA.

[0038] (4) The obtained film was characterized by an ultraviolet spectrophotometer, and its absorption wavelength in the ultraviolet absorption spectrum was 420 nm. When the membrane was placed in Tris / HCl buffer solution of pH=9.0 with different ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com