Natural antibacterial adsorption ultrafine powder and preparation method thereof

An ultra-fine powder, natural antibacterial technology, applied in botanical equipment and methods, chemical instruments and methods, other chemical processes, etc., can solve the problems of complex preparation process, low efficiency, limited development and promotion, etc., to achieve adsorption performance The effect of lifting, high specific surface area, good decontamination effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The preparation method of the present embodiment comprises the following steps:

[0027] (1) Carry out pretreatment to raw material eggshell and shell, remove residual impurity;

[0028] (2) crushing the pretreated eggshells and shells to 120 μm;

[0029] (3) Sintering the pulverized shells and eggshells at 510° C. for 4 hours, and cooling to room temperature;

[0030] (4) grinding the sintered and cooled shell powder and egg shell powder;

[0031] (5) adding hot water to the ground shell powder and eggshell powder to form a suspension;

[0032] (6) heating and stirring the suspension at 110° C. for 7 hours;

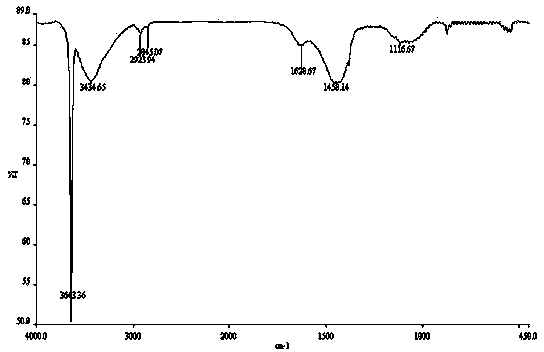

[0033] (7) The suspension after described heating is filtered, separates out powder and dry, cool, and the infrared spectrum of gained powder shows that calcium carbonate and a small amount of calcium oxide are mainly in this powder, as figure 1 shown;

[0034] (8) Add a total of 65 parts of the various raw materials according to egg powder and shell powder, ...

Embodiment 2

[0036] The preparation method of the present embodiment comprises the following steps:

[0037] (1) Carry out pretreatment to raw material eggshell and shell, remove residual impurity;

[0038] (2) crushing the pretreated eggshells and shells to 200 μm;

[0039] (3) Sintering the pulverized shells and eggshells at 550° C. for 3 hours, and cooling to room temperature;

[0040] (4) grinding the sintered and cooled shell powder and egg shell powder;

[0041] (5) adding hot water to the ground shell powder and eggshell powder to form a suspension;

[0042] (6) heating and stirring the suspension at 120° C. for 6 hours;

[0043] (7) filtering the heated suspension, separating out powder and drying and cooling;

[0044] (8) Add a total of 75 parts of the various raw materials according to egg powder and shell powder, 10 parts of sodium bicarbonate, and 15 parts of lipase into the dry powder mixer and stir for 25 minutes, and the finished product is discharged.

[0045] The pres...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com