Potassium fertilizer granules and granulating method thereof

A potash fertilizer and granule technology, applied in potash fertilizers, inorganic fertilizers, fertilization devices and other directions, can solve the problems of difficult operation of agglomeration granulation process, high cost of melt spray granulation, irregular potash fertilizer granules, etc., and achieve excellent biodegradation performance, Low cost and good liquidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

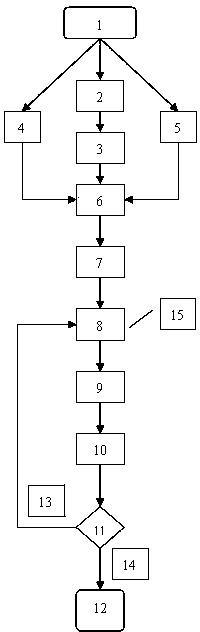

Image

Examples

Embodiment 1

[0043] 1) Weigh 85kg of potassium chloride powder, 14kg of thermoplastic starch, 0.4kg of stearic acid, and 0.6kg of tributyl phosphate, and mix the materials evenly.

[0044] 2) Use a twin-screw extruder with a screw diameter of 65mm, a length-to-diameter ratio of 20:1, and two sets of compression screw blocks in the compression section.

[0045] 3) The temperature of each zone of the twin-screw extruder is set as follows: feed section 90°C, conveying section 120°C, mixing section 130°C, compression section 120°C, die 100°C, screw speed set at 150r / min.

[0046] 4) Send the mixed material in step 1) into the twin-screw extruder with each parameter set, after feeding, conveying, mixing, compressing, and finally extruding through the die, and cutting into pellets.

[0047] 5) Cool and sieve the potash fertilizer granules to obtain qualified potash fertilizer granules: the particle size is 3±1mm, the nutrient content is 47, and the particle strength is 59N.

[0048]

Embodiment 2

[0050] 1) Weigh 86 kg of potassium sulfate powder, 12 kg of thermoplastic starch, 1 kg of stearic acid, and 1 kg of isopropyl trioleoyl titanate, and mix the materials evenly.

[0051] 2) Choose a twin-screw extruder with a screw diameter of 85mm, a length-to-diameter ratio of 25:1, and two sets of compression screw blocks in the compression section.

[0052] 3) The temperature of each zone of the twin-screw extruder is set as follows: the feed section is 100°C, the conveying section is 120°C, the mixing section is 130°C, the compression section is 120°C, the die is 100°C, and the screw speed is set to 200r / min.

[0053] 4) Send the mixed material in step 1) into the twin-screw extruder with each parameter set, after feeding, conveying, mixing, compressing, and finally extruding through the die, and cutting into pellets.

[0054] 5) Cool and sieve the potassium fertilizer granules to obtain qualified potassium fertilizer granules: particle size 3±1mm, nutrient content 45, part...

Embodiment 3

[0057] 1) Weigh 87kg of potassium chloride powder, 10kg of thermoplastic starch, 1kg of low molecular weight polyethylene, and 2kg of tributyl phosphate, and mix the materials evenly.

[0058] 2) Use a twin-screw extruder with a screw diameter of 105mm, a length-to-diameter ratio of 25:1, and two sets of compression screw blocks in the compression section.

[0059] 3) The temperature of each zone of the twin-screw extruder is set as follows: the feed section is 100°C, the conveying section is 120°C, the mixing section is 130°C, the compression section is 120°C, the die is 110°C, and the screw speed is set to 200r / min.

[0060] 4) Send the mixed material in step 1) into the twin-screw extruder with each parameter set, after feeding, conveying, mixing, compressing, and finally extruding through the die, and cutting into pellets.

[0061] 5) Cool and sieve the potash fertilizer granules to obtain qualified potash fertilizer granules: particle size 3±1mm, nutrient content 48, part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com