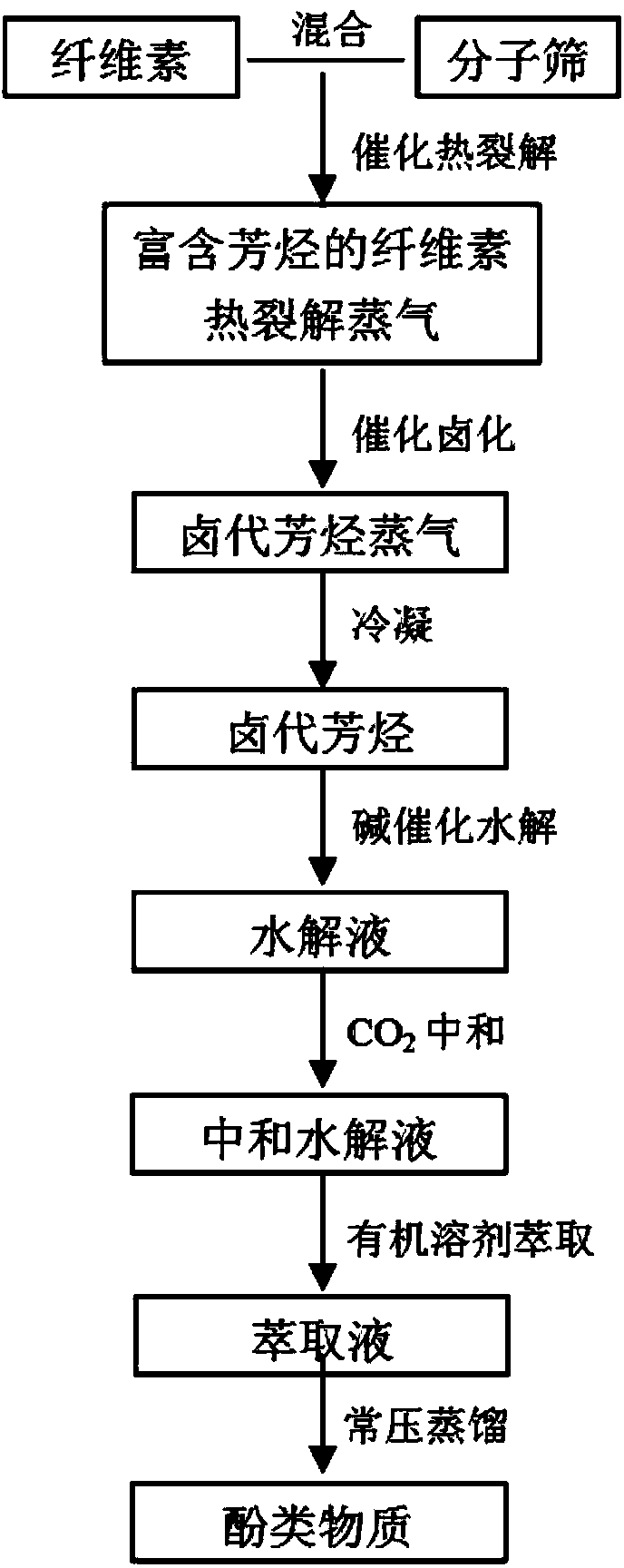

Method for preparing phenolic substances through catalytic pyrolysis conversion of cellulose

A technology of catalytic pyrolysis and phenolic substances, applied in the field of cellulose catalytic pyrolysis conversion to prepare phenolic substances, to achieve the effect of improving the utilization value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Taking the β-cellulose extracted from wheat straw as raw material to introduce the implementation process of the present invention is as follows:

[0036] Mix the cellulose raw material and HZSM-5 molecular sieve evenly at a mass ratio of 1:5, and react at 600°C for 5 seconds under a nitrogen atmosphere. The gas generated after the reaction reacts with chlorine gas under the action of an iron powder catalyst, and the reaction volume space velocity is 1000h -1 , the reaction temperature is 300°C, the reaction pressure is 0.1Mpa, and the reaction time is 30 seconds. The gas after the reaction is condensed at 0°C to generate liquid halogenated aromatic hydrocarbons; Hydrolyze under the condition of ℃, when the pH of the solution is 7.5, the material is discharged to obtain the hydrolyzed solution; carbon dioxide gas is passed into the hydrolyzed solution, and when the pH=4.5, the carbon dioxide gas is stopped to generate a neutralized hydrolyzed solution; Extract the neut...

Embodiment 3

[0041] Taking the microcrystalline cellulose extracted from rice straw as raw material to introduce the implementation process of the present invention is as follows:

[0042] Mix the cellulose raw material and HY molecular sieve evenly at a mass ratio of 1:30, and react at 650°C under a nitrogen atmosphere for 10 seconds. The gas generated after the reaction reacts with bromine chloride gas under the action of ferric chloride catalyst, and the reaction volume is empty Speed is 5000h -1 , the reaction temperature is 500°C, the reaction pressure is 0.3Mpa, and the reaction time is 30 seconds. The gas after the reaction is condensed at a temperature of 10°C to generate liquid halogenated aromatic hydrocarbons; Hydrolyze under the condition of ℃, when the pH of the solution is 7, the material is discharged to obtain the hydrolyzed solution; carbon dioxide gas is passed into the hydrolyzed solution, and when the pH=4, the carbon dioxide gas is stopped to generate a neutralized h...

Embodiment 4

[0044] Taking the microcrystalline cellulose extracted from bagasse as raw material to introduce the implementation process of the present invention is as follows:

[0045] Mix the cellulose raw material with the mixed molecular sieve of HZSM-5 and NaY at a mass ratio of 1:25, and react for 8 seconds at 625°C under a nitrogen atmosphere. The gas generated after the reaction and the bromine chloride gas act on the aluminum chloride catalyst Under the reaction, the reaction volume space velocity is 3000h -1 , the reaction temperature is 450°C, the reaction pressure is 0.4Mpa, and the reaction time is 10 seconds. The gas after the reaction is condensed at a temperature of 5°C to generate liquid halogenated aromatic hydrocarbons; in 5mol / L potassium hydroxide solution, 70 Hydrolyze under the condition of ℃, when the pH of the solution is 7.5, the material is discharged to obtain a hydrolyzed solution; carbon dioxide gas is passed into the hydrolyzed solution, and when the pH=4.5, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com