Lignin flame-retardant fiberboard adhesive and production method thereof

A production method and technology of flame retardant fibers, which are applied in the field of lignin flame retardant fiberboard adhesives, can solve the problems of formaldehyde residue and formaldehyde free, and achieve the effects of high bonding strength, low surface tension and improved adhesive performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

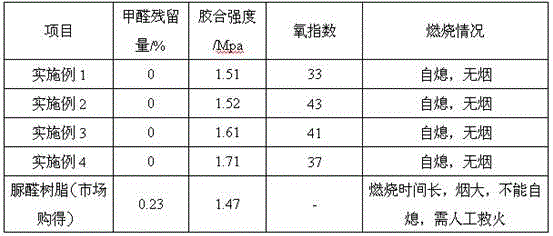

Examples

Embodiment 1

[0027] Embodiment 1 Lignin flame-retardant fiberboard adhesive production formula and method 1

[0028] Recipe composition:

[0029] 25 parts of lignin;

[0030] 25 parts of phenol;

[0031] 15 parts tapioca starch;

[0032] 0.5 parts of vinyltriethoxysilane;

[0033] 0.5 parts of anilinomethyltriethoxysilane;

[0034] 5 parts of ammonium polyphosphate;

[0035] Polydimethylsiloxane 0.1 part.

[0036] Production method: Firstly, the obtained lignin is subjected to a pretreatment reaction to obtain a lignin modified product, and then tapioca starch, vinyltriethoxysilane and anilinomethyltriethoxy are added to the stirred reactor according to the formula ratio Mix silane, ammonium polyphosphate and defoamer evenly, and grind for 1 hour with a three-roll mill to obtain an adhesive with a viscosity of 0.15 Pa·s at 18-20°C

[0037] Lignin modified products are prepared by the following methods:

[0038] (1) Preparation of lignin: add 50wt% sulfuric acid to the pulp black liqu...

Embodiment 2

[0040] Example 2 Production formula and method of lignin flame-retardant fiberboard adhesive 2

[0041] Recipe composition:

[0042] 20 parts of lignin;

[0043] 20 parts of phenol;

[0044] 18 parts of potato starch;

[0045] Anilinomethyltriethoxysilane 1 part

[0046] 1 part of γ-chloropropyltrimethoxysilane;

[0047] 10 parts of magnesium hydroxide;

[0048] Tributyl phosphate 0.1 parts

[0049] Production method: Firstly, the obtained lignin is subjected to a pretreatment reaction to obtain a modified lignin product, and then potato starch, anilinomethyltriethoxysilane and γ-chloropropyltrimethylsilane are added to the stirred reactor according to the formula ratio Oxysilane, magnesium hydroxide and defoamer are mixed evenly, and then ground for 1 hour with a three-roll mill to obtain an adhesive with a viscosity of 0.35 Pa·s at 18-20°C.

[0050] Lignin modified products are prepared by the following methods:

[0051] (1) Preparation of lignin: add 50wt% sulfuric ...

Embodiment 3

[0053] Example 3 Production formula and method of lignin flame-retardant fiberboard adhesive 3

[0054] Recipe composition:

[0055] 30 parts of lignin;

[0056] 30 parts of phenol;

[0057] 20 parts flour;

[0058] 2 parts of γ-methacryloxypropyltrimethoxysilane;

[0059] 1 part of 3-(2,3 glycidoxy) propyltrimethoxysilane;

[0060] 2 parts of mercaptopropyltrimethoxysilane;

[0061] 3 parts of triphenyl phosphate;

[0062] 4 parts of melamine cyanurate;

[0063] Polydimethylsiloxane 0.18 parts.

[0064] Production method: Firstly, the obtained lignin is subjected to a pretreatment reaction to obtain a lignin modified product, and then flour, γ-methacryloxypropyltrimethoxysilane and 3 - (2,3 glycidoxy)propyltrimethoxysilane, mercaptopropyltrimethoxysilane, melamine cyanurate, triphenyl phosphate and defoamer, mix well and grind with a three-roll mill After 2 hours, an adhesive with a viscosity of 0.50 Pa·s at 18-20° C. was obtained.

[0065] Lignin modified products ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com