Method for measuring thickness of chromium film on photomask

A technology for photolithographic mask plate and thickness measurement, which is applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of inability to measure the thickness of metal thin films and cannot expand, and achieve the effects of convenient operation, low cost, and simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

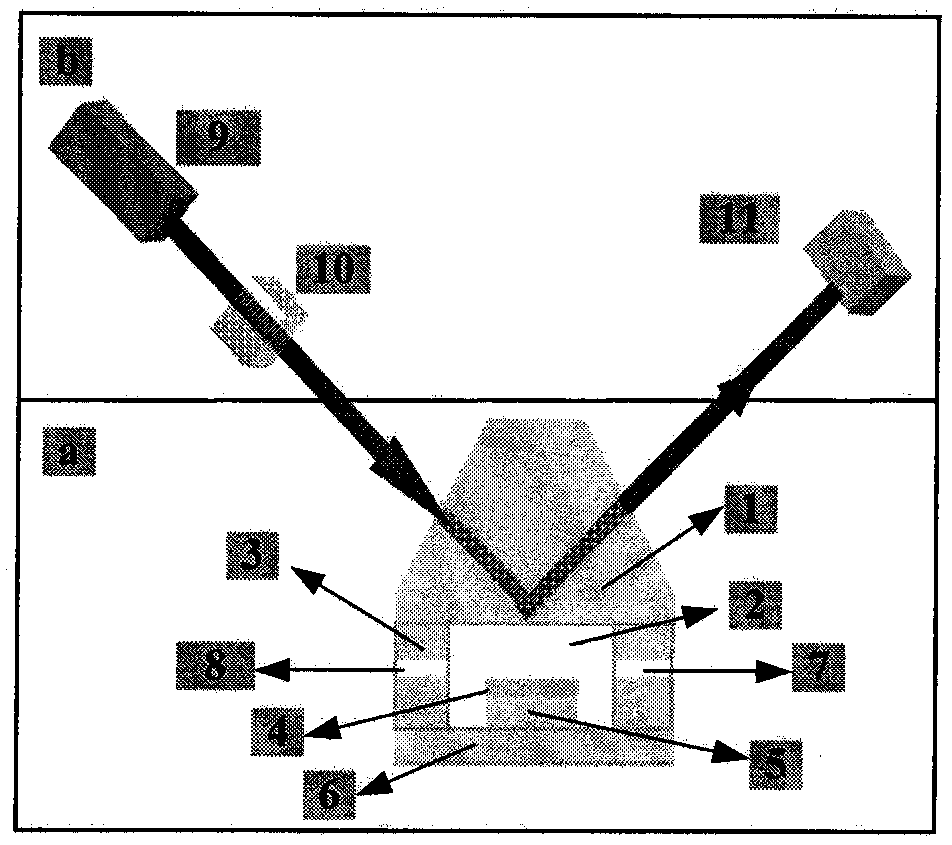

Method used

Image

Examples

Embodiment 1

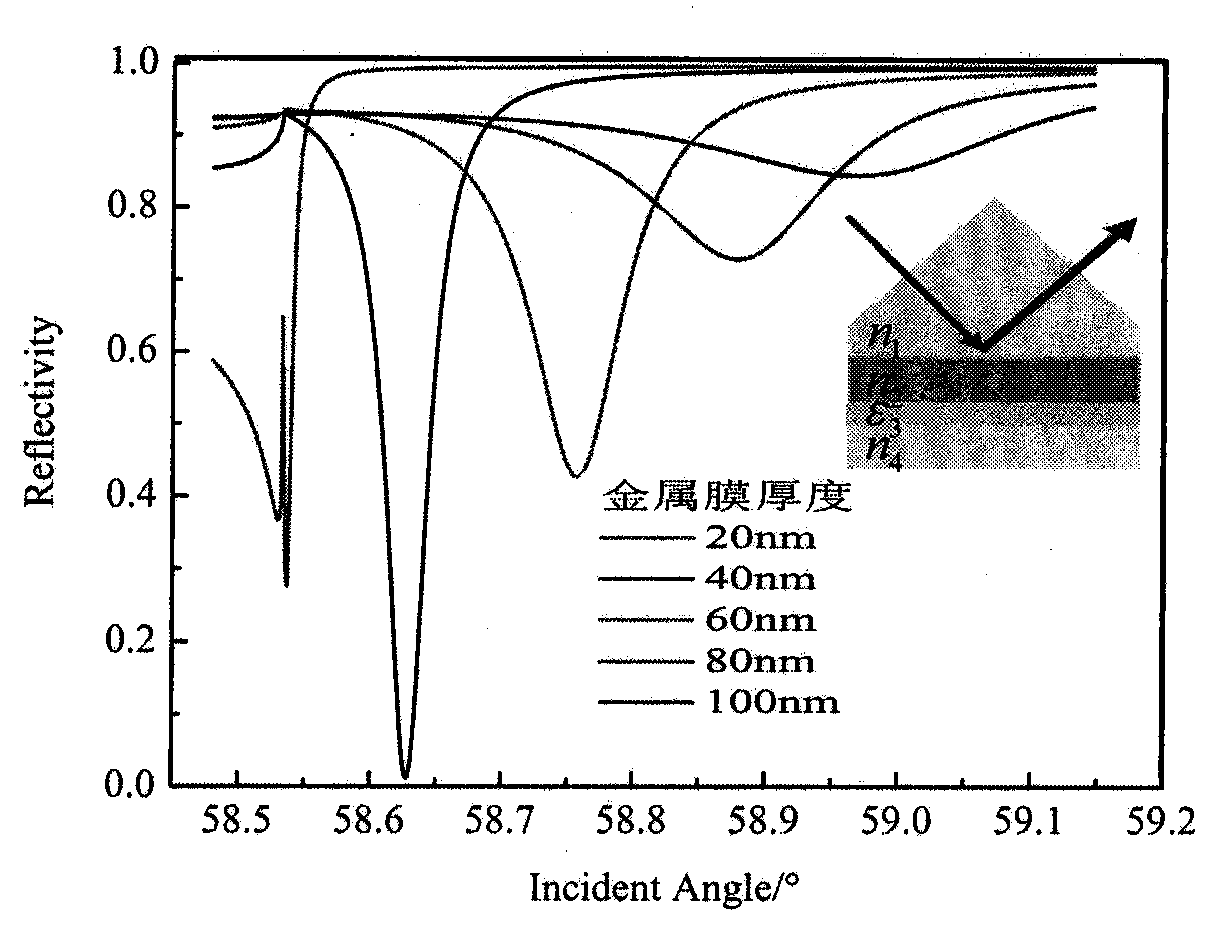

[0020] Suppose the wavelength of the incident laser light λ=3.391um, the refractive index of the glass prism n 1 =1.70, the refractive index n of matching liquid and quartz glass 2 =n 4 =1.45, the thickness h of matching liquid 2 =8.5um, the dielectric coefficient ε of the chromium film 3 =-120+i68, the measuring range of chromium film thickness is 5nm~20nm. When the incident light changes within 58.45°~59.15°, the curve obtained according to the computer simulation is as follows picture 2. Depend on picture It can be seen that using the mid-infrared laser to excite the long-range surface plasmon resonance, since the angular position of the ATR absorption peak of the long-range surface plasmon resonance is a sensitive function of the thickness of the chromium film, the thickness of the chromium film can be accurately measured by this method, and the resolution of the measurement is greater than 0.003° / nm.

Embodiment 2

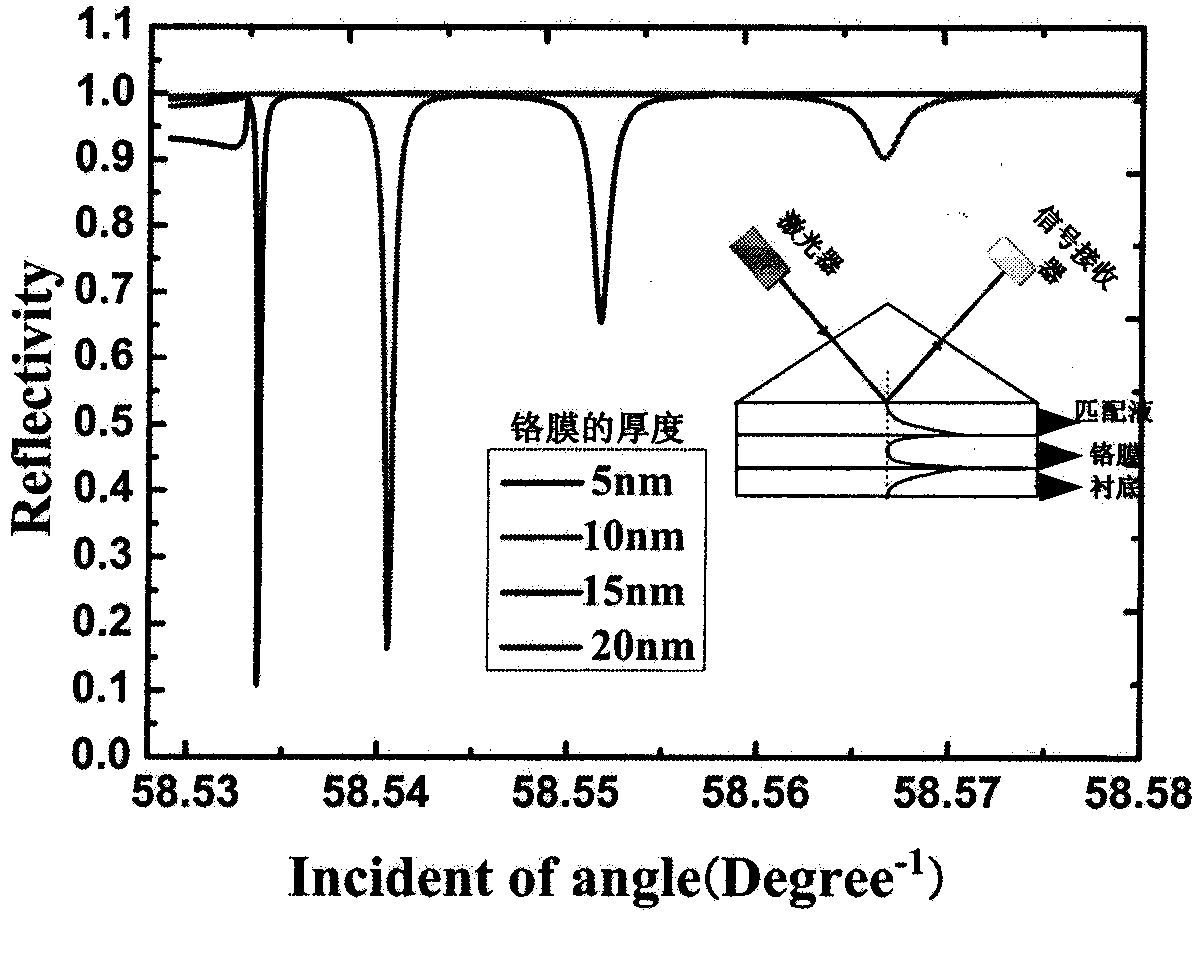

[0022] Suppose the wavelength of the incident laser light λ=3.391um, the refractive index of the glass prism n 1 =1.70, the refractive index n of matching liquid and quartz glass 2 =n 4 =1.45, the thickness h of matching liquid 2 =40um, the dielectric coefficient ε of the chromium film 3 =-120+i68, the measuring range of chromium film thickness is 20nm~100nm. When the incident light changes within 58.534°~58.567°, the curve obtained according to the computer simulation is as follows picture 3. Depend on picture It can be seen that using the mid-infrared laser to excite the long-range surface plasmon resonance, since the angular position of the ATR absorption peak of the long-range surface plasmon resonance is a sensitive function of the thickness of the chromium film, the thickness of the chromium film can be accurately measured by this method, and the resolution of the measurement is greater than 0.001° / nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com