A kind of high-temperature primer for subway wheels and preparation method thereof

A primer and high temperature technology, which is applied to the high temperature primer for subway wheels and its preparation, can solve the problems of poor adhesion performance, room temperature drying performance, solvent resistance performance, poor adhesion, and high toxicity, and achieves the construction environment. Low requirements, good physical and mechanical properties, good chemical resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

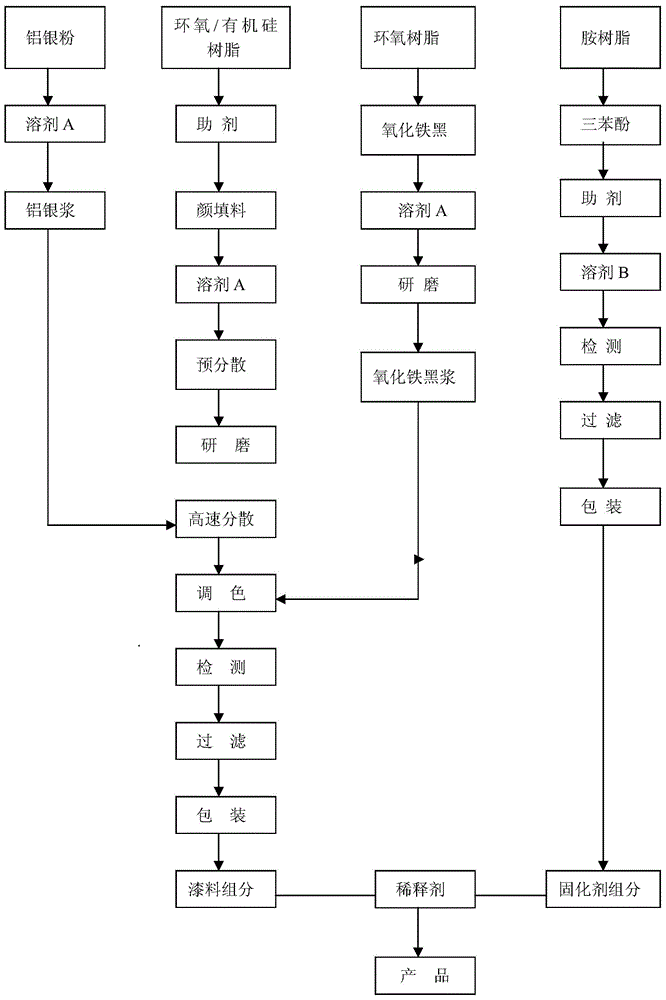

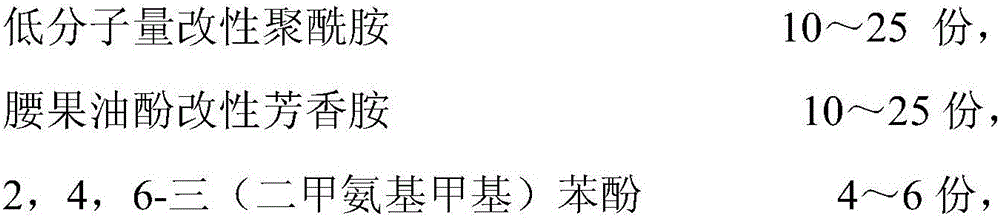

[0052] A method for preparing a high-temperature primer for subway wheels, characterized in that the high-temperature primer for subway wheels includes three parts: a base paint for a high-temperature primer, a curing agent for a high-temperature primer, and a diluent for a high-temperature primer. Made with the following ingredients and steps:

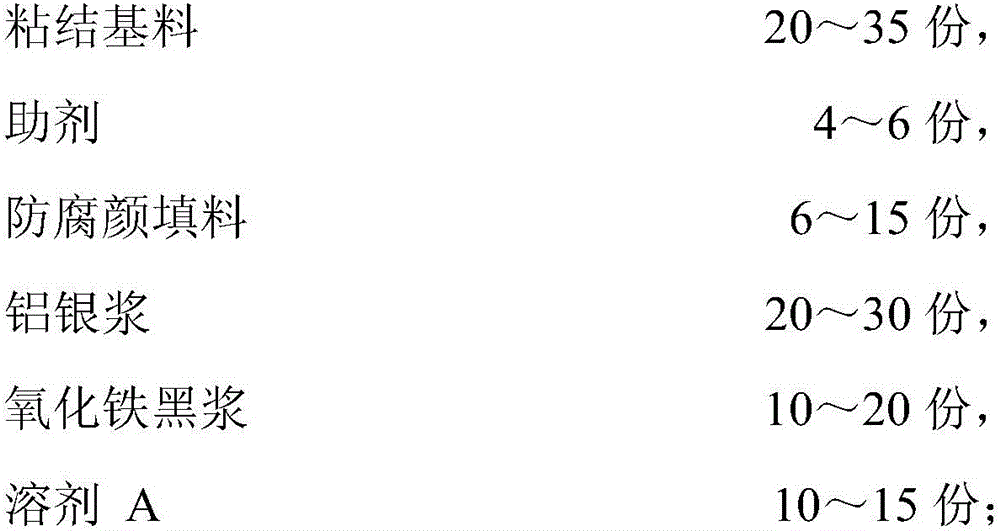

[0053] (1) the weight ratio of each raw material of the basic paint material of the high-temperature primer for the described subway wheel is:

[0054]

[0055] Wherein, the bonding base material is one of methyl phenyl silicone resin and E-20 bisphenol A epoxy resin and E-44 bisphenol A epoxy resin, or two composites;

[0056] Anti-corrosion pigments and fillers are one of mica powder, zinc phosphate, aluminum tripolyphosphate, barium metaborate, ceramic powder, low-temperature glass powder, talc powder, iron oxide series, or a mixture of several;

[0057] The aluminum silver paste is a mixture of aluminum silver powder with high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com