A kind of preparation method of composite cotton fabric electrode for flexible supercapacitor

A technology for supercapacitors and cotton fabrics, used in hybrid capacitor electrodes, hybrid/electric double layer capacitor manufacturing, double layer capacitors, etc. The equipment requires the effect of low performance, stable cycle characteristics, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

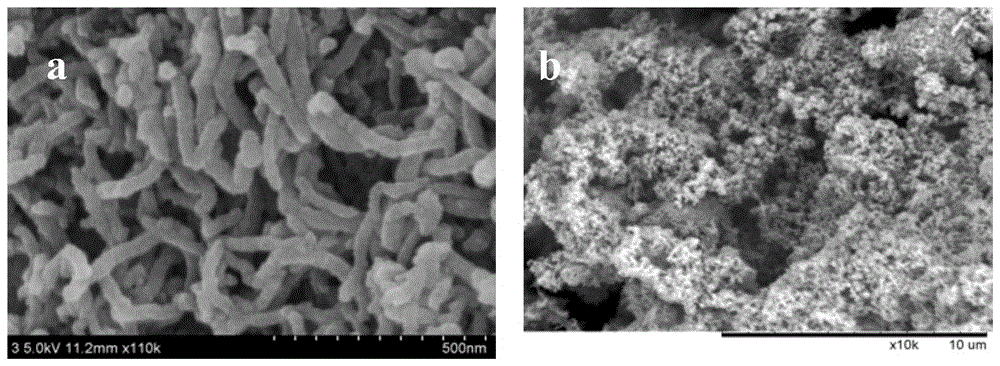

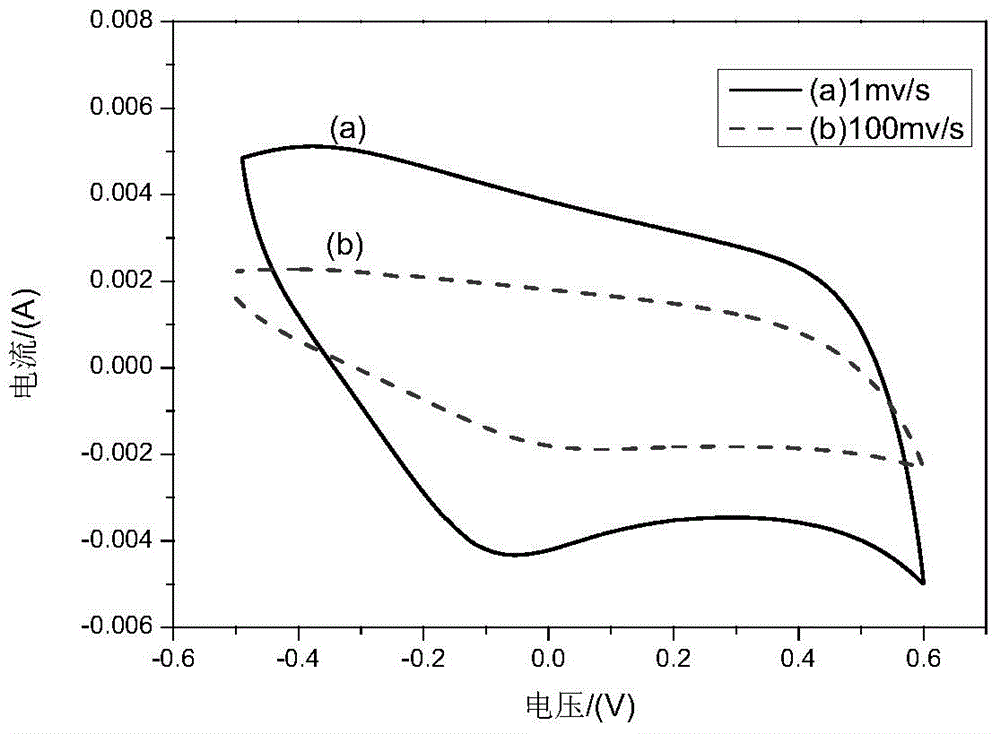

Embodiment 1

[0029] Add multi-walled carbon nanotubes to an aqueous solution composed of 0.005mol / L sodium dodecylbenzenesulfonate and 0.005mol / L hexadecyltrimethylammonium bromide, and disperse them ultrasonically for 60 minutes to form 0.1wt carbon nanotubes % of dispersion A; in dispersion A, add in the aqueous solution that contains 0.002mol / L cetyltrimethylammonium bromide and 0.4mol / L pyrrole, make solution B after ultrasonic vibration 20min; Immerse in solution B for 30min at room temperature, with a bath ratio of 1:50; then add dropwise 0.6mol / L ferric chloride solution C of the same volume as solution B while stirring; after the addition is complete, place the mixture in an ice-water bath ( 0°C) for 120 minutes, after the end, soak in ethanol for 10 minutes and 0.1mol / L hydrochloric acid for 30 minutes, and finally wash with deionized water.

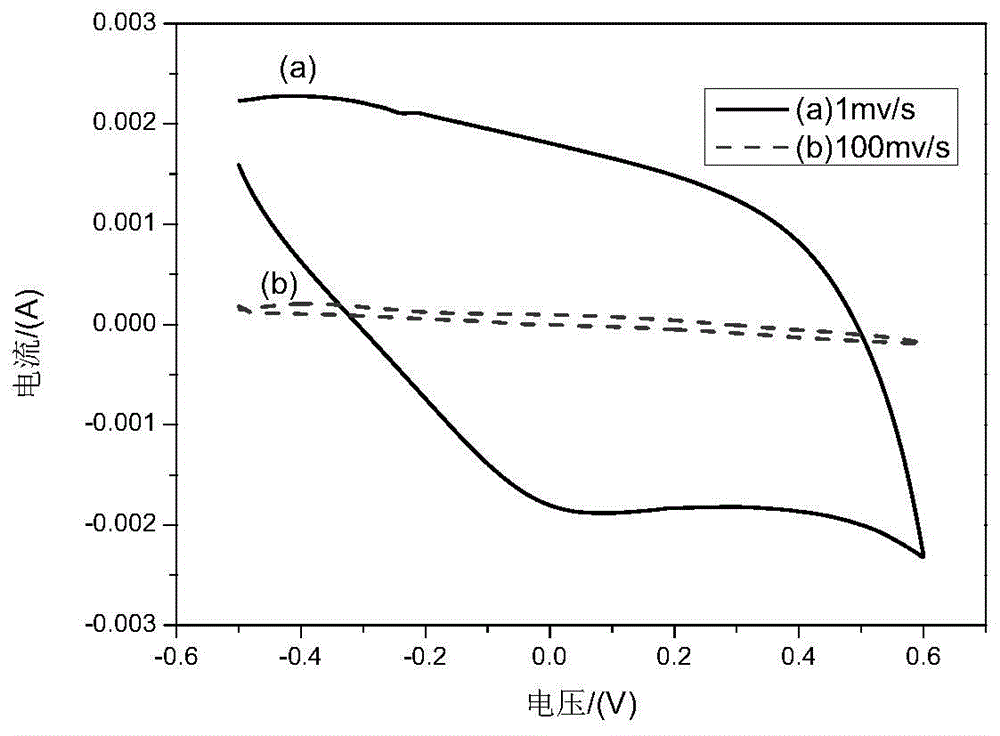

Embodiment 2

[0031] Add single-walled carbon nanotubes to an aqueous solution consisting of 0.006mol / L sodium dodecylsulfonate and 0.004mol / L cetyltrimethylammonium bromide, and ultrasonically disperse them for 60 minutes to form 0.1wt% carbon nanotubes Dispersion A; add to the dispersion A the aqueous solution containing 0.002mol / L dodecyltrimethylammonium bromide and 0.5mol / L aniline, and make solution B after ultrasonic vibration for 30min; put the cotton fabric at room temperature Immerse in solution B for 40min, bath ratio 1:60; then add dropwise 0.6mol / L ammonium persulfate solution C with the same volume as solution B while stirring; ) for 150 minutes, after the end, soak in ethanol for 10 minutes and 0.1mol / L hydrochloric acid for 30 minutes, and finally wash with deionized water.

Embodiment 3

[0033]Add single-walled carbon nanotubes to an aqueous solution composed of 0.005mol / L sodium dodecylsulfonate and 0.003mol / L cetyltrimethylammonium bromide, and ultrasonically disperse them for 60 minutes to form 0.1wt% carbon nanotubes Dispersion A; add to the dispersion A the aqueous solution containing 0.002mol / L dodecyltrimethylammonium bromide and 0.4mol / L aniline, and make solution B after ultrasonic oscillation for 20min; put the cotton fabric at room temperature Immerse in solution B for 30min at a bath ratio of 1:50; then add dropwise 0.5mol / L ammonium persulfate solution C with the same volume as solution B while stirring; ) for 120 minutes, after the end, soak in ethanol for 10 minutes and 0.1mol / L hydrochloric acid for 30 minutes, and finally wash with deionized water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com