Method for producing pinacolone by using fluidized bed process

A pinaconone and fluidized bed technology, applied in the field of fluidized bed process production of pinaconone, can solve the problems of environmental pollution of waste catalysts and low production capacity, and achieve the advantages of improving competitiveness, simple production equipment and solving environmental protection problems. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] According to the titanium / aluminum / cerium molar ratio of 3:1:0.1, take 5000ml of aluminum nitrate, titanium tetrachloride and cerium nitrate to make a mixed solution, and use sodium hydroxide precipitant at 60°C and pH 7-8 Neutralization, washing the filter cake with water until the content of impurity ions is less than 0.1%, adding an appropriate amount of binder to the filter cake, and granulating by spray drying. The spray inlet temperature is 370±2°C, the outlet temperature is 185±2°C, and the average particle size of the catalyst is 85 microns.

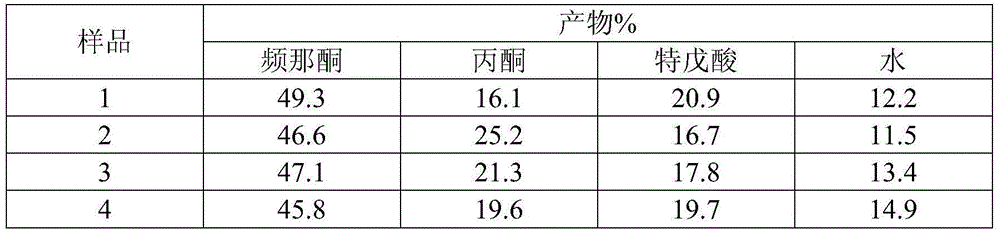

[0016] Add 30g of the prepared catalyst into the reactor, the raw material pivalic acid, acetic acid / acetone molar ratio is 1:1.2, the reactor temperature is 410±2°C, and the space velocity is 0.7. Continuously react for 4 hours, take a sample every hour, and analyze the samples in the collector by chromatography.

[0017] The regenerator temperature is 520±2°C. Add 3.5% (volume percent) methanol to the air. The air flo...

Embodiment 2

[0019] According to the titanium / aluminum / cerium molar ratio of 3:1.5:0.5, take 5000ml of aluminum sulfate, titanium sulfate and cerium nitrate to make a mixed solution, and neutralize it with the precipitant sodium carbonate at 670°C and pH 7-8. The filter cake is washed with water until the content of impurity ions is less than 0.1%, and an appropriate amount of binder is added to the filter cake, and the filter cake is granulated by spray drying. The spray inlet temperature is 370±2°C, the outlet temperature is 185±2°C, and the average particle size of the catalyst is 75 microns.

[0020] Add 30g of the prepared catalyst into the reactor, the raw material pivalic acid, acetic acid / acetone molar ratio is 1:1.2, the reactor temperature is 410±2°C, and the space velocity is 0.8h -1 . Continuously react for 4 hours, take a sample every hour, and analyze the samples in the collector by chromatography.

[0021] The regenerator temperature is 520±2°C. Add 3.5% (volume percent) ...

Embodiment 3

[0023] According to the titanium / aluminum / cerium molar ratio of 3:1.5:0.1, take 5000ml of aluminum nitrate, titanium tetrachloride and cerium nitrate to make a mixed solution, and make a mixed solution with the precipitating agent sodium hydroxide at 70°C and pH 7-8. Neutralization, washing the filter cake with water until the content of impurity ions is less than 0.1%, adding an appropriate amount of binder to the filter cake, and granulating by spray drying. The spray inlet temperature is 370±2°C, the outlet temperature is 185±2°C, and the average particle size of the catalyst is 70 microns.

[0024] Add 30g of the prepared catalyst into the reactor, the raw material pivalic acid, acetic acid / acetone molar ratio is 1:1.2, the reactor temperature is 405±2°C, and the space velocity is 0.7h -1 . Continuously react for 4 hours, take a sample every hour, and analyze the samples in the collector by chromatography.

[0025] The regenerator temperature is 530±2°C. Add 4.5% (volum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com