PH responsive fluorescent carbon nanoparticle hybrid microgel and preparation method thereof

A carbon nanoparticle and microgel technology, which is applied in the chemical industry, can solve problems that limit the practical application of hydrogels, and achieve good pH responsiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

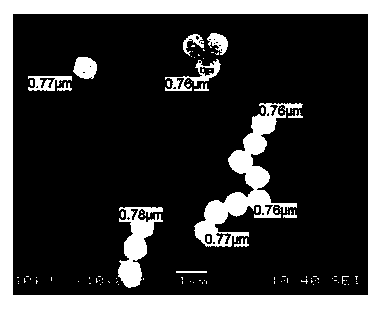

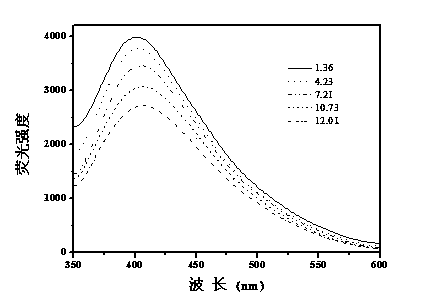

[0025] Weigh an appropriate amount of fluorescent carbon nanoparticles 100 mg, dissolve in dichloromethane, prepare a fluorescent carbon particle solution with a concentration of 0.5-10 mg / mL, add 4 mg of acryloyl chloride, react at room temperature for 10 h, remove the reaction solvent, add water, spin After drying, double-bonded fluorescent carbon nanoparticles are obtained.

[0026] Weigh 40 mg of double-bonded fluorescent carbon particles, add 20 mL of distilled water, and transfer it to a three-neck flask equipped with a stirrer, a reflux condenser, and a thermometer. Turn on the stirrer and evenly ventilate nitrogen to completely exhaust the air in the container and the solution. Add 5 mg of cross-linking agent N-N methylenebisacrylamide, 5 mg of sodium dodecylsulfonate (SDS) and 600 mg of refined acrylic acid. Continue nitrogen sparging to completely vent the container and solution of air. Heating, after the reaction solution starts to reflux, weigh 5 mg of potassium ...

Embodiment 2

[0028] Weigh an appropriate amount of 100 mg of fluorescent carbon nanoparticles, dissolve them in dichloromethane, and prepare a fluorescent carbon particle solution with a concentration of 0.5-10 mg / mL. Add 4 mg of acryloyl chloride. After reacting at room temperature for 10 h, the reaction solvent was removed, water was added, and double-bonded fluorescent carbon nanoparticles were obtained after spin-drying.

[0029] Weigh 35 mg of double-bonded fluorescent carbon particles, add 100 mL of distilled water, and transfer it to a three-necked flask equipped with a stirrer, a reflux condenser, and a thermometer. Turn on the stirrer and evenly ventilate nitrogen to completely exhaust the air in the container and the solution. Add 8 mg of cross-linking agent N-N methylenebisacrylamide, 10 mg of sodium dodecylsulfonate (SDS) and 550 mg of refined acrylic acid. Continue nitrogen sparging to completely vent the container and solution of air. Heating, after the reaction solution s...

Embodiment 3

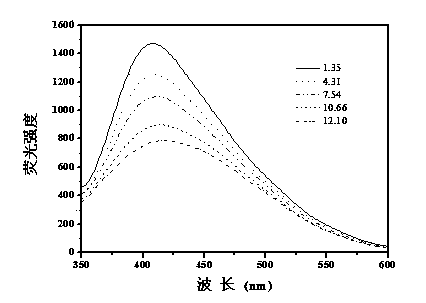

[0031] Weigh an appropriate amount of 100 mg of fluorescent carbon nanoparticles, dissolve them in dichloromethane, and prepare a fluorescent carbon particle solution with a concentration of 0.5-10 mg / mL. Add 5 mg of acryloyl chloride. After reacting at room temperature for 10 h, the reaction solvent was removed, water was added, and double-bonded fluorescent carbon nanoparticles were obtained after spin-drying.

[0032] Weigh 30 mg of double-bonded fluorescent carbon particles, add 100 mL of distilled water, and transfer it to a three-necked flask equipped with a stirrer, a reflux condenser, and a thermometer. Turn on the stirrer and evenly ventilate nitrogen to completely exhaust the air in the container and the solution. Add 10 mg cross-linking agent N-N methylenebisacrylamide, 10 mg sodium dodecylsulfonate (SDS) and 600 mg refined acrylic acid. Continue nitrogen sparging to completely vent the container and solution of air. Heating, after the reaction solution starts to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com