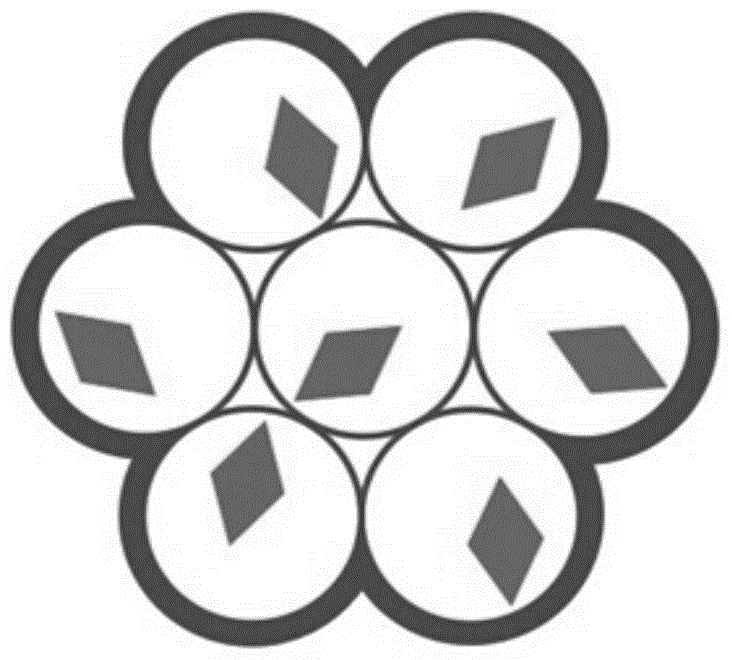

A silicon-carbon composite electrode material with core-shell structure and preparation method thereof

A core-shell structure and electrode material technology, applied in structural parts, battery electrodes, circuits, etc., can solve the problems of low specific capacity, large volume expansion, poor cycle performance, etc., to prevent mutual agglomeration, improve capacity, and good conductivity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

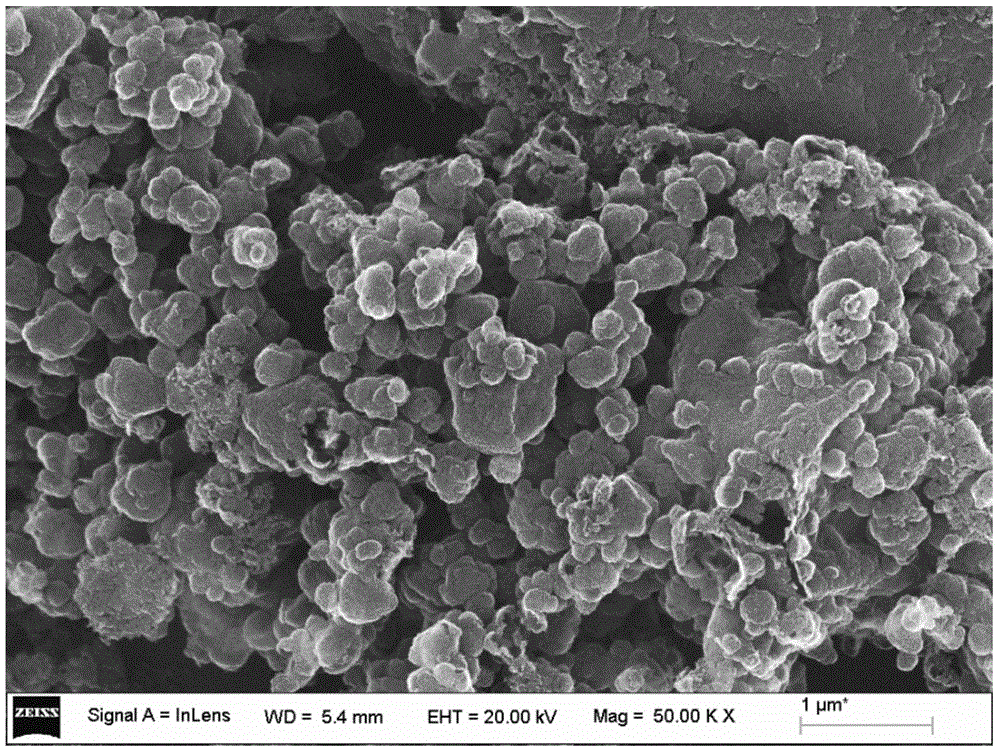

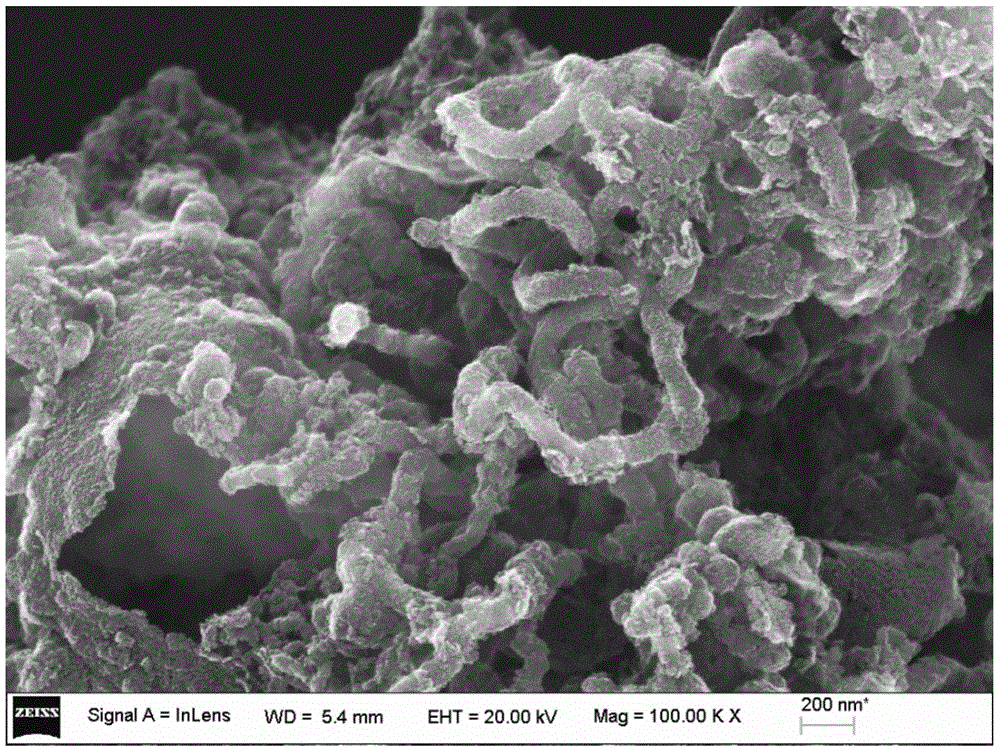

Embodiment 1

[0032] Disperse 400 mg of negative electrode active material silicon monoxide (purity mass fraction greater than or equal to 99.99%, particle diameter is 100-300 nanometers) after ball mill ball milling in 320 milliliters of ethanol and 80 milliliters of deionized water, ultrasonically make it Disperse evenly, then add 4 ml of concentrated ammonia water (mass fraction 28%), the pH value is between 7-9. Subsequently, under vigorous stirring (stirring rate 600-800rpm), 1.6 ml of ethyl orthosilicate was added into the dispersion, and the stirring state was kept for 12 hours to obtain a silica-coated product. 200 mg of the obtained coated silicon dioxide sample was placed in a tube furnace reactor, and nitrogen gas was introduced at a flow rate of 100 ml / min. Raise the temperature to 620°C, replace the acetylene / nitrogen mixed gas (the volume fraction of acetylene content is 5%) with chemical vapor deposition gas, the flow rate is 100 ml / min, keep the temperature at 620°C for 20 m...

Embodiment 2

[0034]Disperse 400 mg of negative electrode active material silicon monoxide (purity mass fraction greater than or equal to 99.99%, particle diameter is 100-300 nanometers) after ball mill ball milling in 320 milliliters of ethanol and 80 milliliters of deionized water, and make it Disperse evenly, then add 4 milliliters of concentrated ammonia water (mass fraction 28%). Subsequently, under vigorous stirring (stirring speed 600-800 rpm), 1.6 ml of ethyl orthosilicate was added into the dispersion, and the stirring state was maintained for 12 hours to obtain a silica-coated product. 200 mg of the obtained coated silicon dioxide sample was placed in a tube furnace reactor, and nitrogen gas was introduced at a flow rate of 100 ml / min. The temperature was raised to 620°C, and the mixed gas of acetylene / nitrogen (the content of acetylene was 5% by volume fraction) was replaced with chemical vapor deposition gas, the flow rate was 100 ml / min, and the acetylene carbon was deposited a...

Embodiment 3

[0036] Disperse 400 mg of negative electrode active material silicon monoxide (purity mass fraction greater than or equal to 99.99%, particle diameter is 100-300 nanometers) after ball mill ball milling in 320 milliliters of ethanol and 80 milliliters of deionized water, and make it Disperse evenly, then add 4 milliliters of concentrated ammonia water (mass fraction 28%). Subsequently, under vigorous stirring (stirring speed 600-800 rpm), 1.6 ml of ethyl orthosilicate was added into the dispersion, and the stirring state was maintained for 12 hours to obtain a silica-coated product. 200 mg of the obtained coated silicon dioxide sample was placed in a tube furnace reactor, and nitrogen gas was introduced at a flow rate of 100 ml / min. Raise the temperature to 620° C., replace the acetylene / nitrogen mixed gas (the volume fraction of acetylene content is 5%) with chemical vapor deposition gas, the flow rate is 100 ml / min, and keep at 620° C. for 1 hour to deposit acetylene carbon....

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com