Methane-nitrogen gas double component separation method and device

A separation method and two-component technology, applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of high energy consumption, resource consumption, low enrichment efficiency, etc., and achieve low equipment investment and no methane Loss, flexible effect of driving and parking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

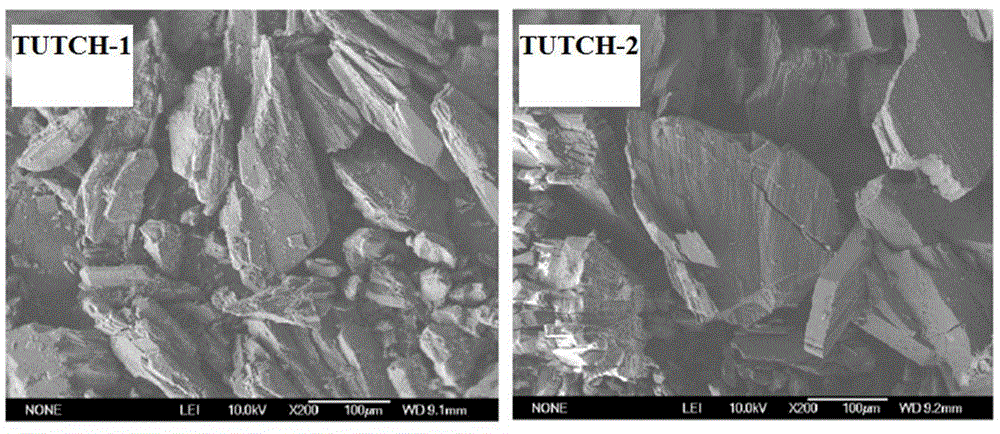

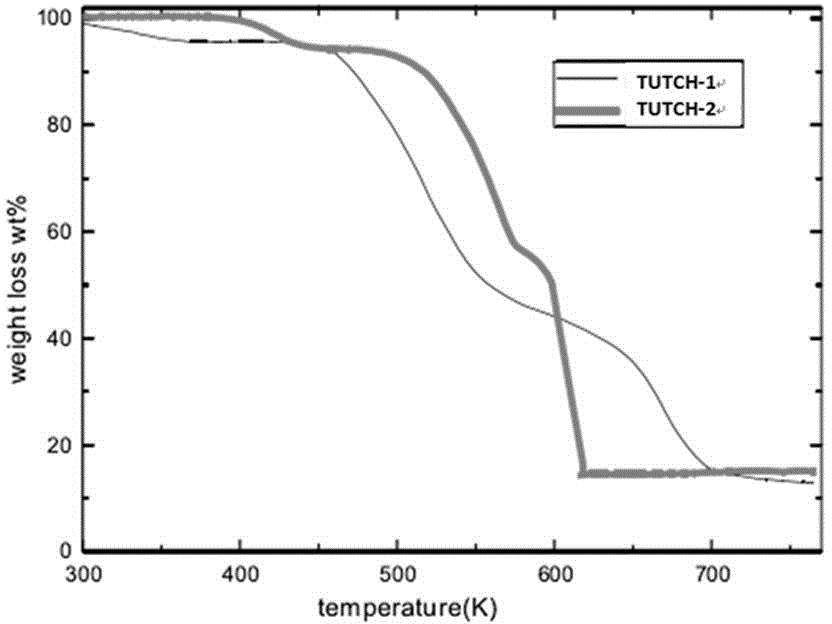

[0024] Preparation of flexible material TUTCH-1

[0025] Weigh 0.5g ± 0.001g of copper nitrate trihydrate, measure 10mL ± 0.001mL of deionized water, place in a beaker, stir and mix for 5min to form a 2mol / L copper nitrate aqueous solution;

[0026] Weigh 0.3g±0.001g of 2,5-dihydroxybenzoic acid, measure 10mL±0.001mL of deionized water, put it in a beaker, stir and mix for 5min to form a 2mol / L aqueous solution of 2,5-dihydroxybenzoic acid;

[0027] Weigh 0.312g±0.001g of 4,4'-bipyridine, measure 10mL±0.001mL of ethanol, put it in a beaker, stir and mix for 5min to form a 2mol / L 4,4'-bipyridine ethanol solution;

[0028] Measure 20mL±0.001mL of copper nitrate aqueous solution and put it in a beaker; measure 20mL±0.001mL of 2,5-dihydroxybenzoic acid aqueous solution into the beaker; measure 40mL±0.001mL of 4,4'-bipyridine ethanol solution and slowly Drop into the beaker, stir while dripping, the dropping speed is 0.5mL / min, mix evenly for 30min.

[0029] The beaker filled wit...

Embodiment 2

[0033] Preparation of flexible material TUTCH-2

[0034] Weigh 0.7g ± 0.001g of copper tetrafluoroborate hexahydrate, measure 10mL ± 0.001mL of deionized water, put it in a beaker, stir and mix for 5min, and form a 2mol / L copper tetrafluoroborate aqueous solution;

[0035] Weigh 0.312g ± 0.001g of 4,4'-bipyridine, measure 10mL ± 0.001mL of ethanol, place in a beaker, stir and mix for 5min to form a 2mol / L 4,4'-bipyridine ethanol solution.

[0036] Measure 20mL±0.001mL of copper tetrafluoroborate aqueous solution and put it in a beaker; measure 40mL±0.001mL of 4,4'-bipyridine ethanol solution and slowly drop it into the beaker, stirring while dropping, the dropping speed is 0.5mL / min, mix well for 30min.

[0037] The beaker filled with the solution was placed in a temperature-controlled magnetic stirrer, and treated at a constant temperature of 25° C. for 120 minutes; the reacted solution was kept at a constant temperature of 25° C., and sealed for 48 hours.

[0038] Filter ...

Embodiment 3

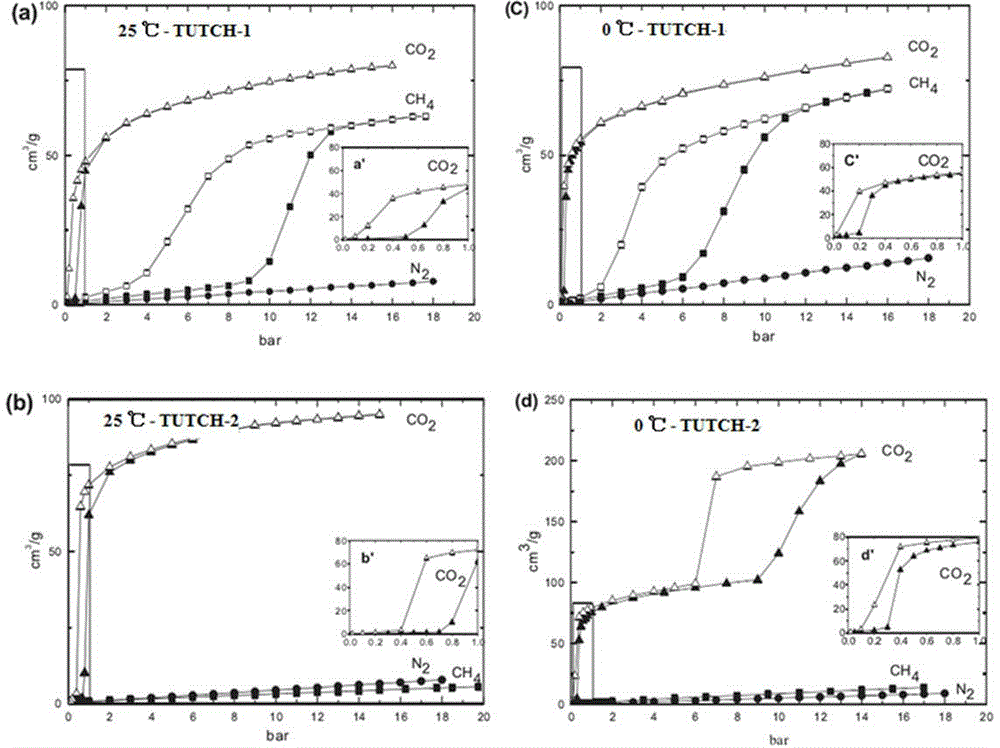

[0044] Embodiment 3 and embodiment 4 are separation CH4 / N2 method, as Figure 4 As shown, the PSA equipment used includes CH4 / N2 mixed feed gas storage tank 1, No. 1 adsorption bed 2 and No. 2 adsorption bed 3, CH4 storage tank 4 and N2 storage tank 5, and the outlet of storage tank 1 is connected to a quality control flowmeter 6 inlets, No. 1 adsorption bed 2 and No. 2 adsorption bed 3 are connected in parallel and equipped with temperature control tank 7 respectively, No. 1 adsorption bed 2 and No. 2 adsorption bed 3 are filled with flexible material TUTCH-1 or flexible material TUTCH-2 as adsorption The inlets of the two adsorption beds are connected to the outlet of the quality control flow meter 6, the outlets of the two adsorption beds are connected to the back pressure valve 8, the CH4 storage tank 4 and the N2 storage tank 5 are connected to the back pressure valve; the first adsorption bed 2 and the second adsorption bed The front and rear sides of the adsorption bed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com