Compound fertilizer for preventing and treating fast-growing eucalyptus red leaf dieback and production method for compound fertilizer

A technology of dead shoots of red leaves and fast-growing eucalyptus, which is applied in the field of pesticides and fertilizers, can solve the problems of difficult spraying operation, difficulty in distinguishing, labor-intensive and time-consuming, etc., and achieves the effects of high control efficiency, reduced removal rate, and reduced use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

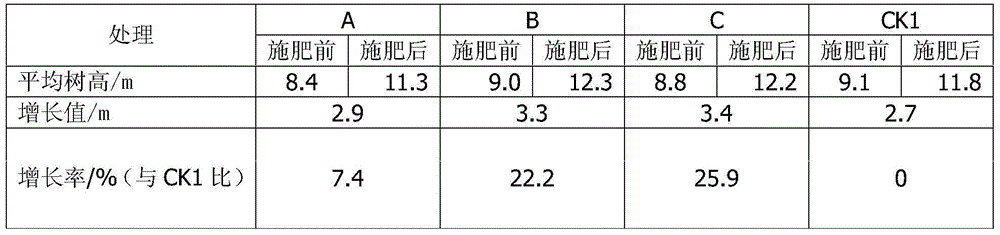

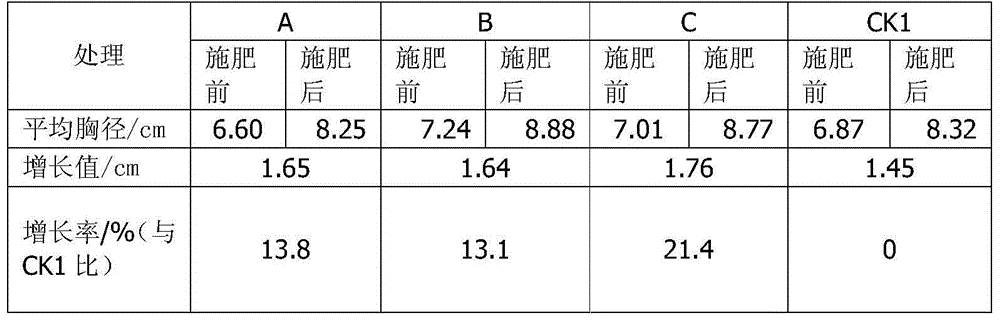

Examples

Embodiment 1

[0030] Example 1 Compound fertilizer for preventing and treating fast-growing eucalyptus red leaf dieback and production method (1)

[0031] Compound fertilizer production process of the present invention is:

[0032] ① Preparation of 25% azoxystrobin wettable powder: according to the processing method of pesticide wettable powder, put 130 kg of azoxystrobin raw powder, 60 kg of sodium lauryl sulfate, 100 kg of calcium lignosulfonate and auxiliary material bentonite into the reaction kettle , after double-helix stirring for 15 minutes, jet crushing, passing through a 375-mesh sieve, and then stirring with a gravity-free mixer for 20 minutes, after passing the test, it is obtained;

[0033] ②Pretreatment of medium and trace elements: after dissolving 275 parts of medium and trace elements borax, 45 parts of copper sulfate, 150 parts of ferrous sulfate, and 45 parts of zinc sulfate in water, add molasses alcohol waste liquid with a concentration of 8-12°BX, and no further Add w...

Embodiment 2

[0037] Example 2 Compound fertilizer for preventing and treating fast-growing eucalyptus red leaf dieback and production method (two)

[0038] Compound fertilizer production process of the present invention is:

[0039] ① Preparation of 25% azoxystrobin wettable powder: according to the processing method of pesticide wettable powder, put 120 kg of azoxystrobin raw powder, 60 kg of sodium lauryl sulfate, 100 kg of calcium lignosulfonate and auxiliary material bentonite into the reaction kettle , after double-helix stirring for 15 minutes, jet crushing, passing through a 375-mesh sieve, and then stirring with a gravity-free mixer for 20 minutes, after passing the test, it is obtained;

[0040] ②Pretreatment of medium and trace elements: after dissolving 460 parts of medium and trace elements borax, 90 parts of copper sulfate, 200 parts of ferrous sulfate and 90 parts of zinc sulfate in water, add molasses alcohol waste liquid with a concentration of 8-12°BX, and no further Add ...

Embodiment 3

[0044] Example 3 Compound fertilizer for preventing and controlling fast-growing eucalyptus red leaf dieback and production method (three)

[0045] Compound fertilizer production process of the present invention is:

[0046] ①Preparation of 25% azoxystrobin wettable powder: according to the processing method of pesticide wettable powder, put 120 kg of azoxystrobin, 60 kg of sodium lauryl sulfate, 100 kg of calcium lignosulfonate and auxiliary material bentonite into the reaction kettle, double After spiral stirring for 15 minutes, jet crushing, passing through a 375-mesh sieve, and stirring with a gravity-free mixer for 20 minutes, after passing the test, it is ready;

[0047] ②Pretreatment of medium and trace elements: after dissolving 727 parts of medium and trace elements borax, 45 parts of copper sulfate, 250 parts of ferrous sulfate, and 130 parts of zinc sulfate in water, add molasses alcohol waste liquid with a concentration of 8-12°BX, and no further Add water to dilu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com