The synthetic method of substituted indole-2-carboxylic acid

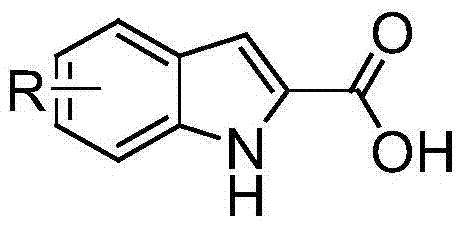

A synthesis method and indole technology, which is applied in the synthesis of important intermediates of medicine and pesticides, and in the field of synthesis of substituted indole-2-carboxylic acid, can solve the problem of waste gas, waste water, waste, unfavorable industrial application, complex process, etc. problems, to achieve environmental friendliness, significant social and economic benefits, and easy access to raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0035] Example 1, the synthesis of indole-2-carboxylic acid

[0036] Using ethanol as a solvent, heat 108 grams of phenylhydrazine, 1 milliliter of acetic acid and 127 grams of ethyl pyruvate in a mixed solvent of 1175 milliliters of ethanol and 235 milliliters of water, reflux at a temperature of 80 ° C, and monitor the completion of the reaction in 3 hours. After solvent, recrystallize with 70% ethanol aqueous solution, filter, and dry to obtain 177 g of light yellow crystal phenylhydrazinepyruvate phenylhydrazone, with a yield of 86%.

[0037] Step 2: Mix 500 grams of polyphosphoric acid and 250 grams of phosphoric acid, stir and heat to 50°C, add 75 grams of raw material phenylhydrazinepyruvate phenylhydrazone in batches, and control the temperature range from 70 to 90°C for 0.5 hours After adding the raw materials, continue the temperature control reaction for 20 minutes, monitor that the reaction is complete, pour it into 1500 grams of ice-water mixture, cool, filter and...

example 2

[0040] The synthesis of example 2,5-fluoroindole-2-formic acid

[0041] Step 1: Using ethanol as a solvent, heat 162.5 grams of 4-fluorophenylhydrazine hydrochloride and 127 grams of ethyl pyruvate in a mixed solvent of 1205 milliliters of ethanol and 241 milliliters of water, and reflux at a temperature of 80 ° C for 4 hours After monitoring the completion of the reaction, after removing the solvent, recrystallize with 70% ethanol aqueous solution, filter, and dry to obtain 186.1 g of light yellow crystal 4-fluorophenylhydrazinepyruvate phenylhydrazone, with a yield of 83%.

[0042] Step 2: Mix 500 grams of polyphosphoric acid and 250 grams of phosphoric acid, stir and heat to 75°C, add 65 grams of raw material 4-fluorophenylhydrazinepyruvate phenylhydrazone in batches, and control the temperature range from 75 to 85°C , add the raw materials in 1 hour, continue the temperature control reaction for 20 minutes, monitor the completion of the reaction, pour it into 1500 grams of...

example 3、5

[0045] The synthesis of example 3,5-chloroindole-2-formic acid

[0046] Using ethanol as a solvent, heat 179.05 grams of 4-chlorophenylhydrazine hydrochloride and 127 grams of ethyl pyruvate in a mixed solvent of 1225 milliliters of methanol and 265 milliliters of water, reflux at a temperature of about 80 ° C, and monitor the reaction for 3 hours Completed, after desolvation, recrystallized with 70% ethanol aqueous solution, filtered, and dried to obtain 219 grams of light yellow crystal 4-chlorophenylhydrazinepyruvate phenylhydrazone, yield 91%.

[0047] Step 2: Mix 500 grams of polyphosphoric acid and 250 grams of phosphoric acid, heat it to 70°C under stirring, add 70 grams of raw material 4-chlorophenylhydrazinepyruvate phenylhydrazone in batches, control the temperature range from 70 to 90°C for 1 hour After adding the raw materials, continue the temperature control reaction for 40 minutes, monitor the completion of the reaction, pour it into 1500 grams of ice-water mixt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com