Composite converting type isotope battery

An isotope battery and battery technology, applied in the field of micro-energy, can solve the problems of reducing the effective utilization rate of rays, reducing conversion performance, failure, etc., and achieving the effects of high battery stability and reliability, large output power density, and wide selection range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

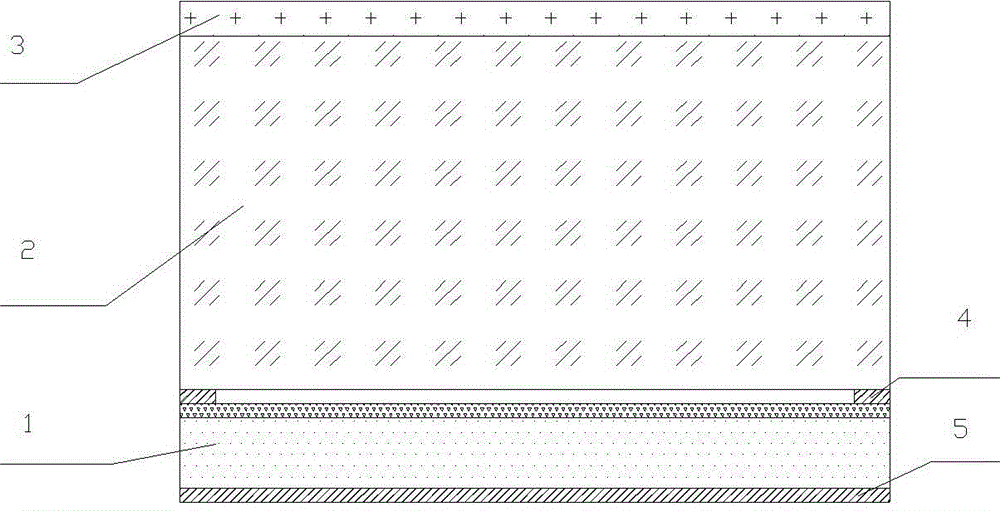

[0022] figure 1 Among them, the transducer device 1 is a monocrystalline silicon PN junction diode prepared by thermal diffusion, the thickness of the base layer is 250 μm, the junction depth is 0.5 μm, and the doping concentration of the base layer is 3×10 15 cm -3 ; The radioluminescence material 2 is a silicate transparent ceramic sheet doped with 4% europium, and the thickness is 5 mm; the loading radiation source 3 is electroplating 147 Pm radiation source; both the battery upper electrode 4 and the battery lower electrode 5 are Ti / Ni / Au with a thickness of 1 micron.

[0023] The working process of the composite isotope battery is: 147 When the Pm radiation source β-ray passes through the radioluminescent material 2 europium-doped silicate transparent ceramic sheet, the low-energy part of the energy spectrum deposits all its energy in the radioluminescent material, and in the process passes through the excitation radiation The luminescent material produces fluorescenc...

Embodiment 2

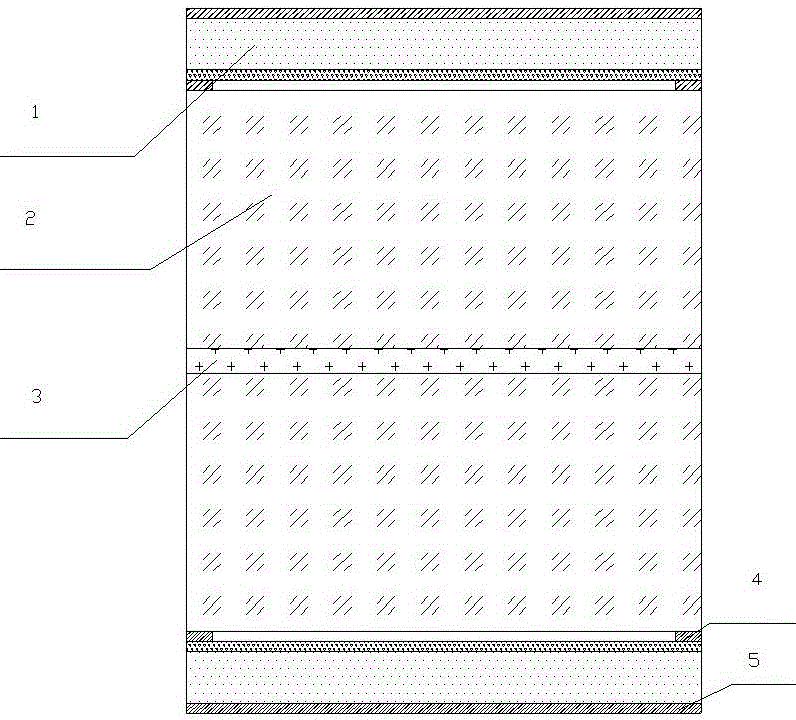

[0025] figure 2 Among them, the transducer device 1 is an epitaxial silicon-based PN junction diode prepared by thermal diffusion, the thickness of the epitaxial layer is 40 μm, the junction depth is 0.5 μm, and the doping concentration of the epitaxial layer is 1×10 16 cm -3 The radioluminescent material 2 is a silicate transparent ceramic sheet doped with 4% europium, and the thickness is 10mm; the loaded radioactive source 3 is prepared by chemical deposition 90 Sr- 90 Y ceramic radiation source; the upper electrode 4 of the battery and the lower electrode 5 of the battery are both Ti / Ni / Au with a thickness of 1 micron.

[0026] The working process of this complex isotope cell is: similar to example 1, 90 Sr- 90 When the gamma radiation source β-ray passes through the radioluminescent material 2 europium-doped silicate transparent ceramic sheet, part of the energy in the ray is deposited in the radioluminescent material to generate light energy; part of the energy of t...

Embodiment 3

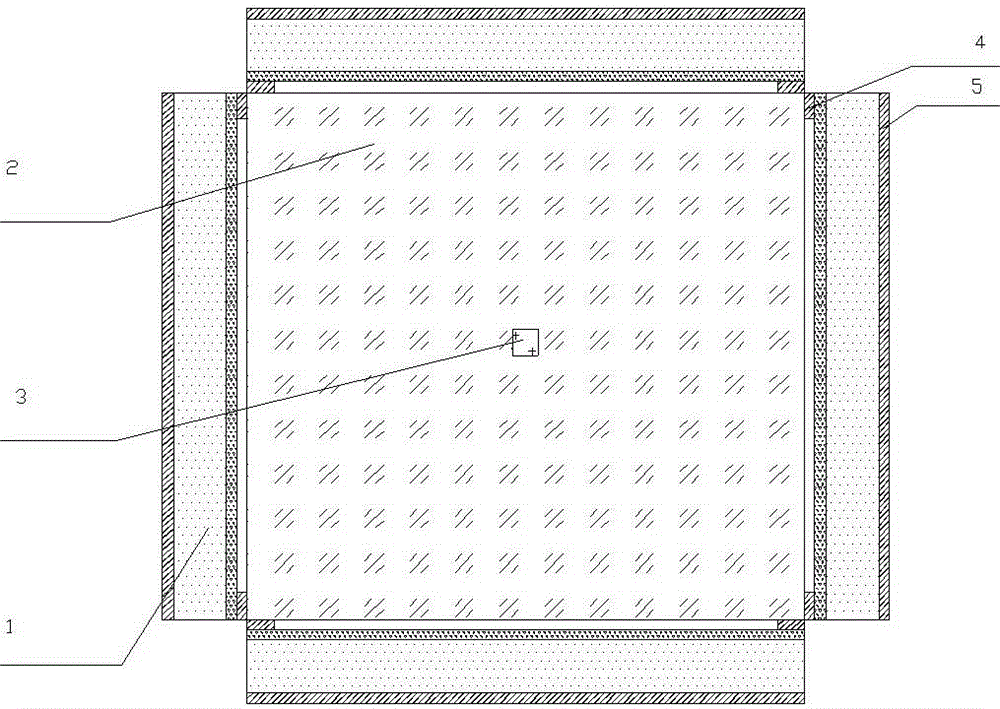

[0029] image 3 Among them, the transducer device 1 is an epitaxial silicon-based PN junction diode prepared by thermal diffusion, the thickness of the epitaxial layer is 40 μm, the junction depth is 0.5 μm, and the doping concentration of the epitaxial layer is 1×10 16 cm -3 ; The radioluminescent material 2 is a plastic scintillator with a wall thickness of 20 mm; the loaded radioactive source 3 is prepared by powder metallurgy 90 Sr- 90 The Y ceramic source is a cube with a size of 10mm×10mm×10mm; the upper electrode 4 of the battery and the lower electrode 5 of the battery are both Ti / Ni / Au with a thickness of 1 micron.

[0030]The working process of this complex isotope battery is the same as that of Example 2, and the radioactive source 3 is loaded 90 Sr- 90 The Y ceramic radiation source is three-dimensionally packaged around the plastic scintillator, and PN junction transducers are placed on the 6 sides of the plastic scintillator cube to fully utilize the 4π emiss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com